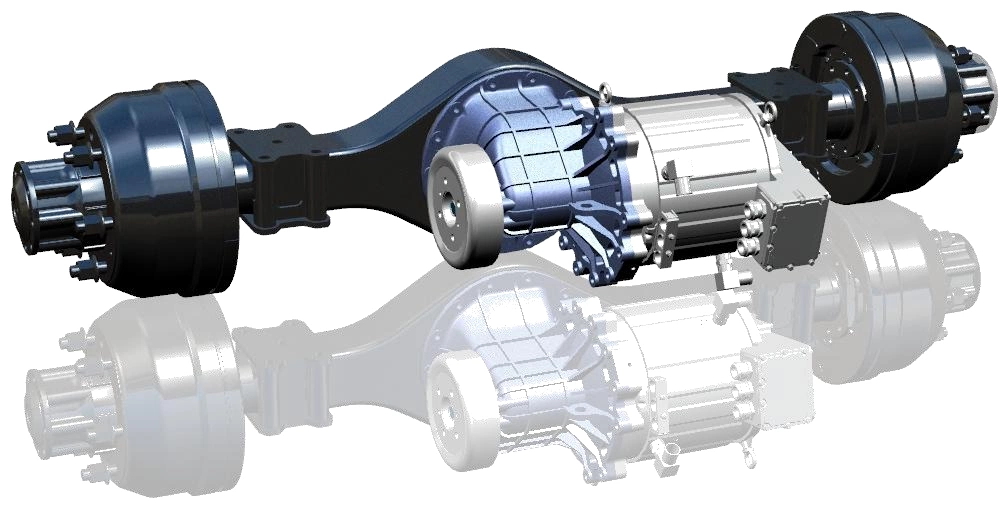

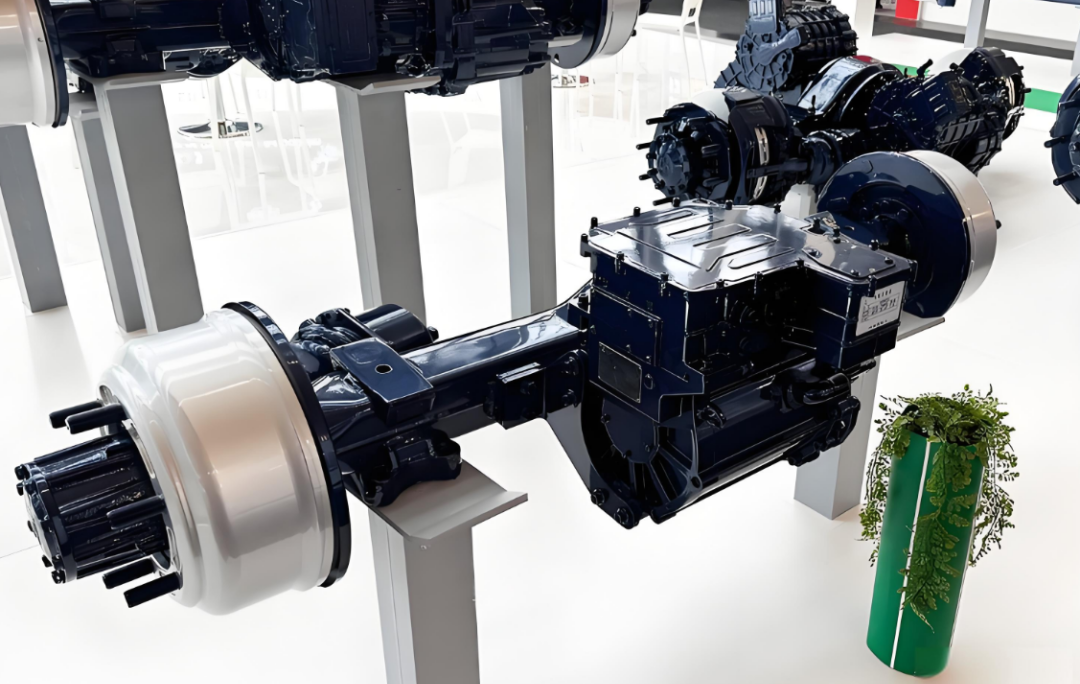

3.5T Rear E-Axle for Minivans/Trucks

Pumbaa 3.5T Rear E-Axle Product Parameters

Model: PMQX2100100A-3.5/160

description2

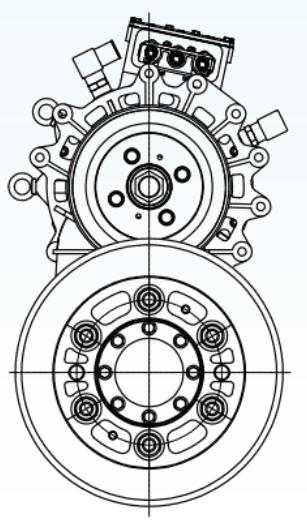

Pumbaa 3.5T Rear E-Axle Structural and Functional Diagram

description2

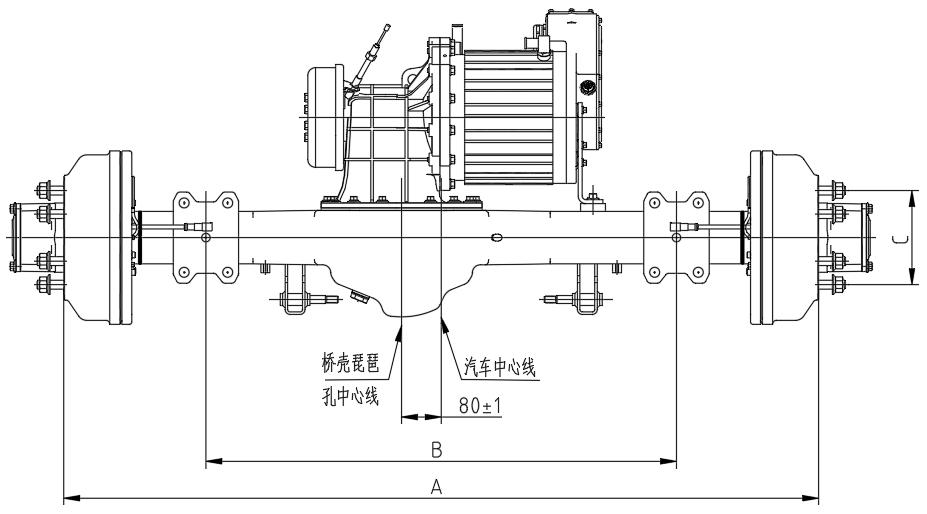

Pumbaa 3.5t Rear E-Axle Configuration Parameters

|

Rated Load(kg) |

3500 |

Gear Ratio |

16.55 |

|

Maximum Load(kg) |

6000 |

Maximum Torque(N.m) |

5800 |

|

Maximum Speed(Km/h) |

≥110 |

Maximum Gradeability |

23% |

|

Sustainable Speed(Km/h) |

80 |

Axle Housing Structural Form |

Stamping and Welding |

|

Rim Mounting Surface Distance A(mm) |

1524±3 |

Axle Housing Cross Section (mm) |

106×106×6 |

|

Spring Distance B ( m m ) |

950±1 |

Brake Specification |

Hydraulic Brake 0310 * 75 (Drum Brake) |

|

Wheel Bolt Circle C(mm) |

ø190 |

Brake Caliper Diameter |

ø28.58 |

|

Wheel Bolt |

6-M18×1.5 |

Brake Hydraulic Line Connection |

M12x1.25 |

|

Rim Lip Diameter |

ø139.8 |

Single Brake Torque |

10Mpa,3100N.m |

|

Compatible Tires |

7.0×R16 |

Hub Mounting Surface Distance |

1496-1612 |

|

Wheel Alignment Method |

Lip Positioning |

Compatible Rims |

5.5J×16 |

|

Optional Configuration |

Maintenance-Free Hub Unit, Pneumatic Brake with S Cam Brake, Pneumatic Brake with Wedge Brake, Disc Brake |

||

|

|

|||

|

Motor Type |

PMSM |

Protection Rating |

IP67 |

|

Motor Peak Power(Kw) |

120 |

Motor Rated Voltage(VDC)(V) |

540 |

|

Motor Rated Power(Kw) |

60 |

Voltage Operating Range(VDC)(V) |

350~750 |

|

Motor Peak Torque(N.m) |

350 |

Motor Maximum Speed(rpm) |

12000 |

|

Motor Rated Torque(N.m) |

125 |

Motor Rated Speed(rpm) |

4580 |

|

Insulation Class |

H |

Duty |

S9 |

description2

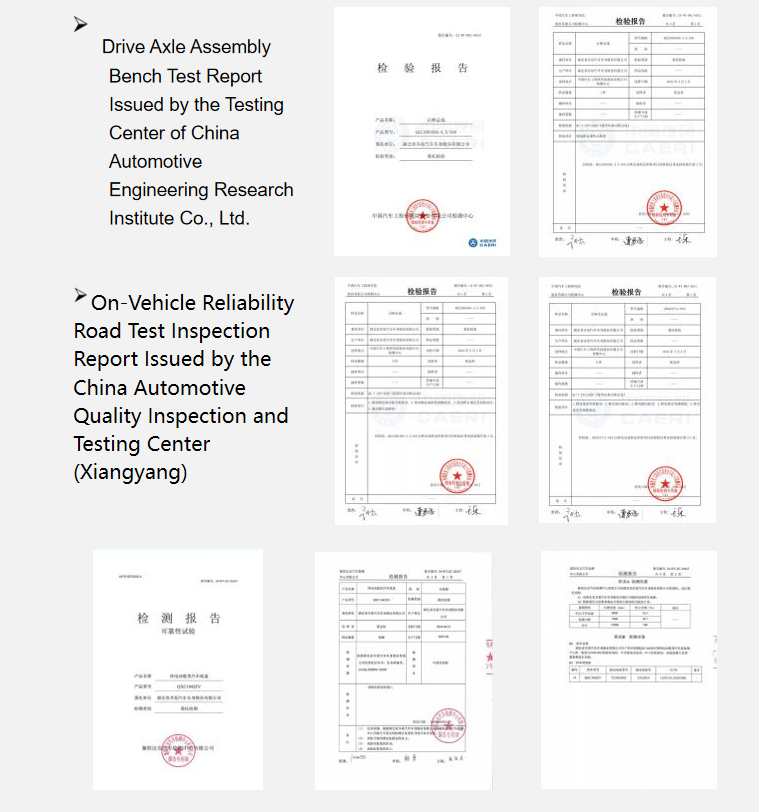

Pumbaa 3.5t Rear E-Axle Inspection and Testing

description2

Vehicle Parameters by Pumbaa 3.5t Rear E-Axle

|

Curb Weight(kg) |

2900 |

|

Full Load/Overloaded Gross Mass(kg) |

4500/6000 |

|

Tire Model, Rolling Radius(mm) |

7.00R16LT、352 |

|

Maximum Gradeability |

23% |

|

Vehicle Maximum Parking Gradeability |

20% |

|

Maximum Speed(km/h) |

110 |

|

Economic Speed(km/h) |

60~80 |

|

0~50km/h Acceleration Time(S) |

≤15 |

|

30~0km/h Braking Distance(m) |

≤9(Unladen)、≤10(Full Load) |

description2

Application for Pumbaa 3.5t Rear E-Axle Products: Electric Mini vans/Trucks

description2

Why Choose an e-axle?

Amid the booming electric vehicle (EV) industry, e-axle are increasingly becoming a popular choice for automakers and consumers alike—backed by numerous significant advantages.

1. Markedly Enhanced Performance

Strong Power & Instant Response: The e-axle integrates the electric motor, reducer, and differential. As the power source, the electric motor efficiently converts electrical energy into mechanical energy. Compared to traditional ICE vehicle powertrains, the motor in an e-axle responds almost instantlywith zero lag. During startup, it delivers powerful torque immediately, enabling rapid acceleration for a smooth, thrilling driving experience. For example, high-performance EVs with advanced e-axle can hit 0-100 km/h in just a few seconds—something traditional ICE vehicles struggle to match.

2. Precise Power Distribution

The differential is a key component of the e-axle. When turning, it allows left and right wheels to rotate at different speeds—ensuring stability and handling in all cornering scenarios, letting drivers control the vehicle’s trajectory with precision. In complex road conditions (e.g., mud, snow), the drive axle further optimizes traction by using electronic controls to distribute power more finely, enhancing the vehicle’s passability.

3. Efficient & Energy-Saving Advantages

Integrated Design Cuts Energy Loss: By combining critical components into a single module, the e-axle shortens the power transmission path. This reduces energy loss between parts—unlike traditional powertrains—allowing electrical energy to be converted into kinetic energy more efficiently. The result? Improved energy utilization, longer EV range, and reduced “range anxiety” for consumers.

Energy Recovery & Reuse: Advanced e-axle feature regenerative braking: when decelerating or braking, the motor acts as a generator, converting the vehicle’s kinetic energy back into stored electricity. This further boosts efficiency, lowers energy consumption, and makes EVs even more eco-friendly.

4. Space Utilization & Design Flexibility

Saves In-Car Space: The integrated design takes up far less room than traditional standalone components (engines, transmissions). This frees up more passenger and cargo space—highly appealing to consumers prioritizing comfort and practicality—and gives designers more freedom to optimize interior layouts.

Streamlines Vehicle Design: With a simpler structure, automakers enjoy greater flexibility in overall vehicle design. They can adjust parameters like ground clearance and wheelbase more freely, improve aerodynamics, and pursue lightweight construction more easily.

5. Lower Maintenance Costs & High Reliability

Reduced Maintenance: Fewer components and a simpler structure mean fewer breakdowns and less frequent servicing compared to ICE powertrains. There’s no need for regular oil changes, spark plug replacements, or other ICE-specific upkeep—cutting owner costs significantly.

Proven Durability: Advances in manufacturing and materials have made e-axle highly reliable. They withstand complex driving conditions and harsh environments, ensuring long-term stable performance for the vehicle.

With its superior performance, energy efficiency, space-saving design, and low maintenance costs, the e-axle has become the ideal choicefor EV development—propelling the electric vehicle industry forward into a more sustainable future.