The PUMBAA EV Motor: High-Efficiency Power for Next-Gen Electric Vehicles

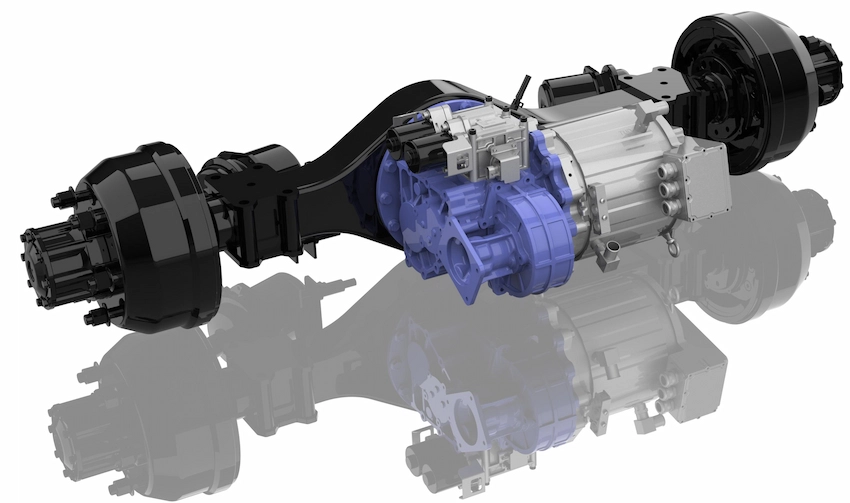

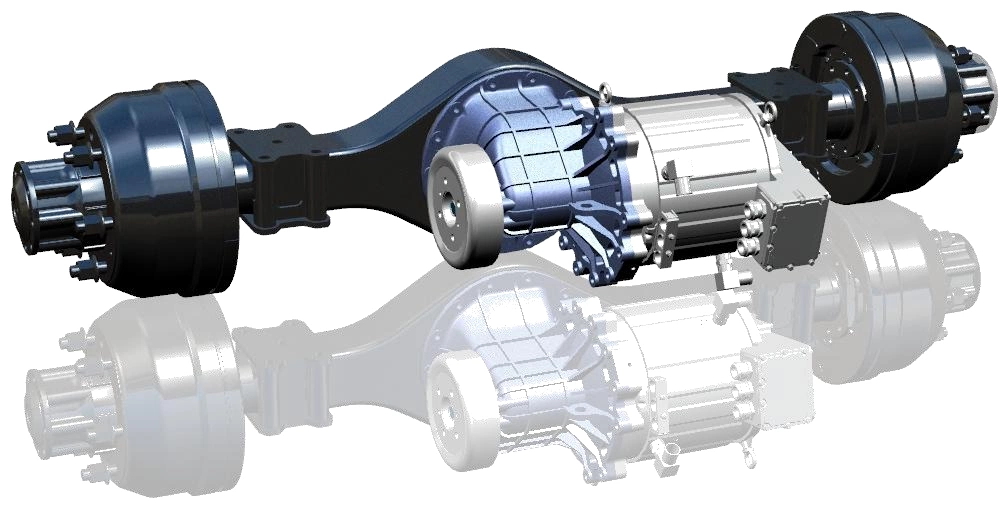

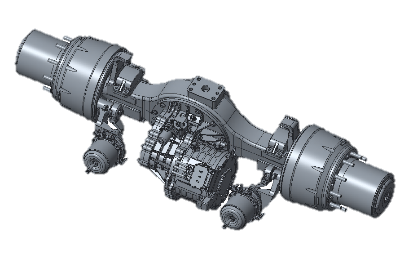

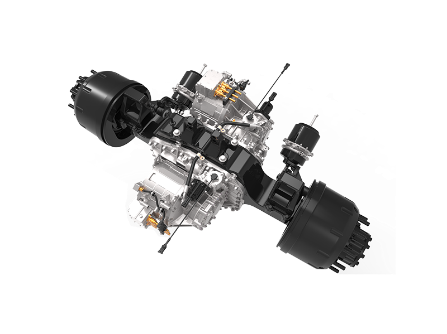

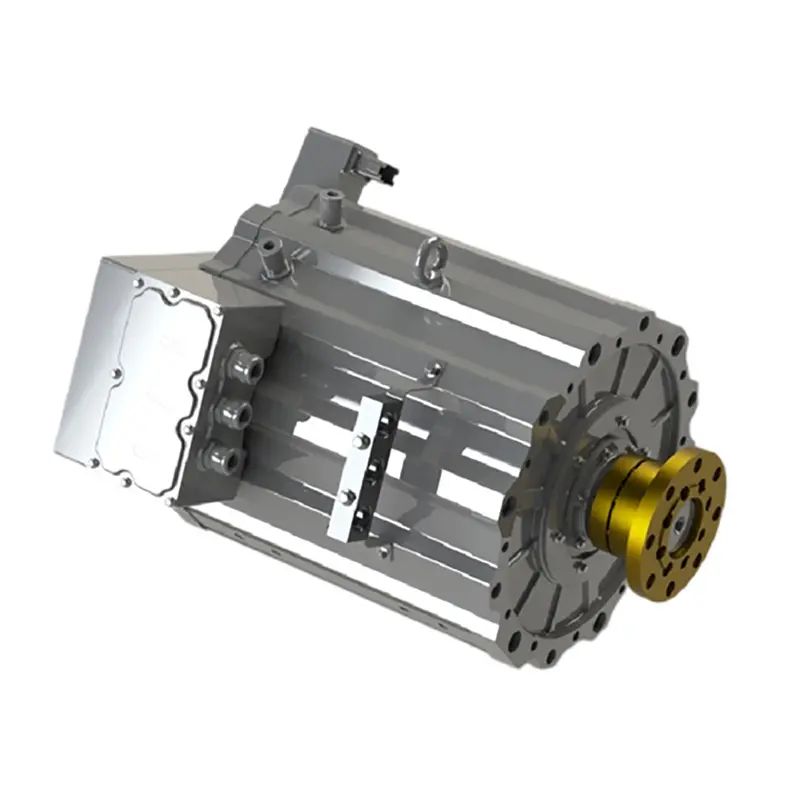

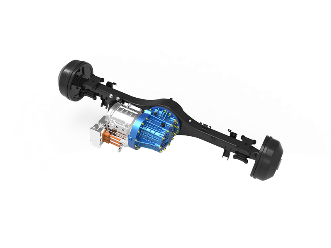

The PUMBAA EV motor is a cutting-edge electric vehicle engine built to deliver high performance, outstanding efficiency, and long-term reliability. As a flagship product in the EV motor kit market, it leverages advanced Permanent Magnet Synchronous Motor (PMSM) technology to provide superior torque density, rapid acceleration, and minimal energy loss—ideal for both OEM integration and custom EV conversions. Whether you're assembling a full EV powertrain or upgrading an existing system, the PUMBAA EV motor kit offers a complete, ready-to-integrate solution.

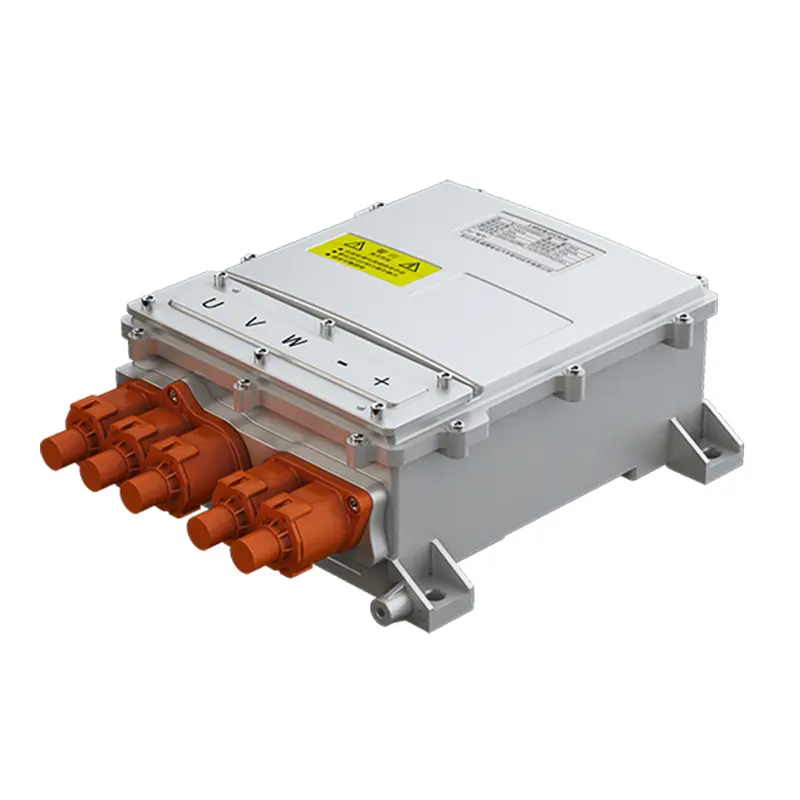

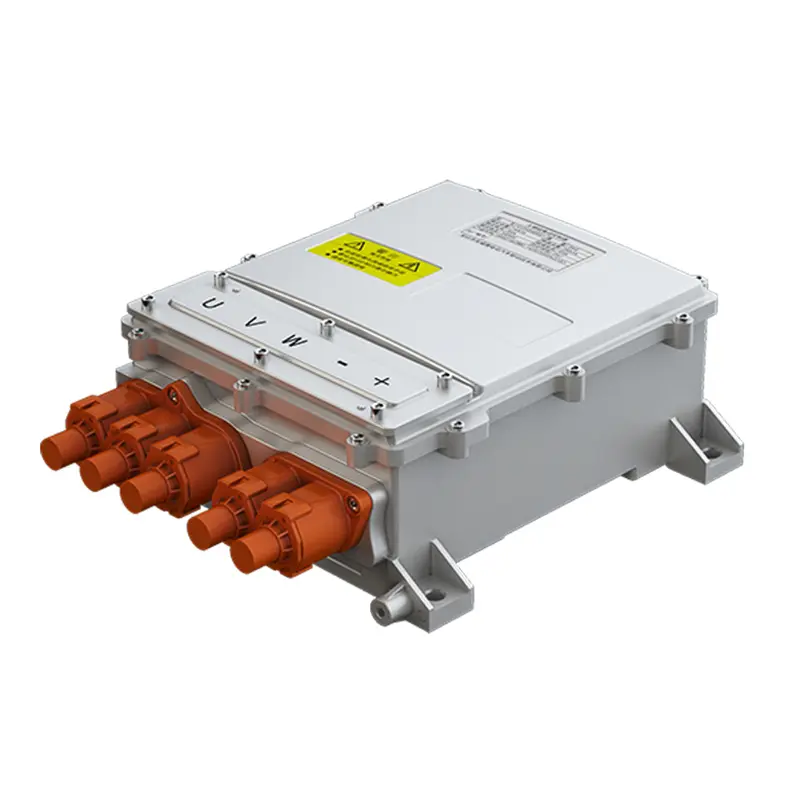

The compact, lightweight design not only ensures space-saving installation but also contributes to overall vehicle efficiency. Thanks to its inverter brushless motor configuration, the system operates with minimal noise and virtually no maintenance, supporting smooth and quiet driving experiences. Engineered for compatibility and scalability, our EV motors for sale can be seamlessly paired with our high-performance inverters and motor controllers, ensuring optimized performance across various load conditions.

From electric sedans to commercial EV platforms, the PUMBAA electric vehicle engine sets a new standard for reliability, responsiveness, and energy conservation. Explore the future of sustainable mobility with the PUMBAA EV motor—where advanced engineering meets real-world performance.

Category list

High Efficiency

Electric motors typically achieve efficiency levels of 85-95%, significantly reducing energy losses compared to internal combustion engines (ICEs). This leads to lower energy consumption and cost savings.

Instant Torque Delivery

Unlike ICEs, electric motors provide immediate torque, resulting in quicker acceleration and smoother driving performance.

Low Maintenance Requirements

With fewer moving parts and no need for oil changes or fuel system maintenance, electric motors require less upkeep and are more reliable over time.

Environmental Benefits

Electric motors produce zero tailpipe emissions, contributing to reduced air pollution and a smaller carbon footprint when powered by renewable energy sources.

High Efficiency

Electric motors typically achieve efficiency levels of 85-95%, significantly reducing energy losses compared to internal combustion engines (ICEs). This leads to lower energy consumption and cost savings.

Instant Torque Delivery

Unlike ICEs, electric motors provide immediate torque, resulting in quicker acceleration and smoother driving performance.

Low Maintenance Requirements

With fewer moving parts and no need for oil changes or fuel system maintenance, electric motors require less upkeep and are more reliable over time.

Environmental Benefits

Electric motors produce zero tailpipe emissions, contributing to reduced air pollution and a smaller carbon footprint when powered by renewable energy sources.

FAQs for electric car motor

PMSMs generally offer higher efficiency across a wide range of speeds due to their reduced rotor losses and higher power density. However, induction motors are favored for cost-sensitive applications or in environments requiring robustness against temperature fluctuations, as they lack rare earth materials.

The choice between liquid and air cooling depends on the motor's power output, thermal tolerance, and vehicle application. High-performance EV motors typically use liquid cooling for superior heat dissipation, enabling prolonged high-power operation. In contrast, air cooling is suitable for smaller or economy-focused EVs with lower thermal loads.

Torque ripple can cause vibrations and reduce the smoothness of vehicle acceleration. High harmonics in the motor drive system may decrease efficiency and increase heat generation. Mitigating these issues requires precision in motor design, including optimized stator winding and advanced control algorithms.

Scalability allows a single motor design to be adapted across various vehicle models by adjusting parameters such as winding configuration or cooling systems. This approach reduces development costs and enhances manufacturing efficiency, making it a cornerstone for EV platforms targeting diverse market segments.

Advanced motor control algorithms, such as field-oriented control (FOC) or direct torque control (DTC), optimize torque and efficiency dynamically. They ensure rapid response to load changes, improve regenerative braking efficiency, and adapt to different terrains or driving styles, significantly enhancing overall vehicle performance.