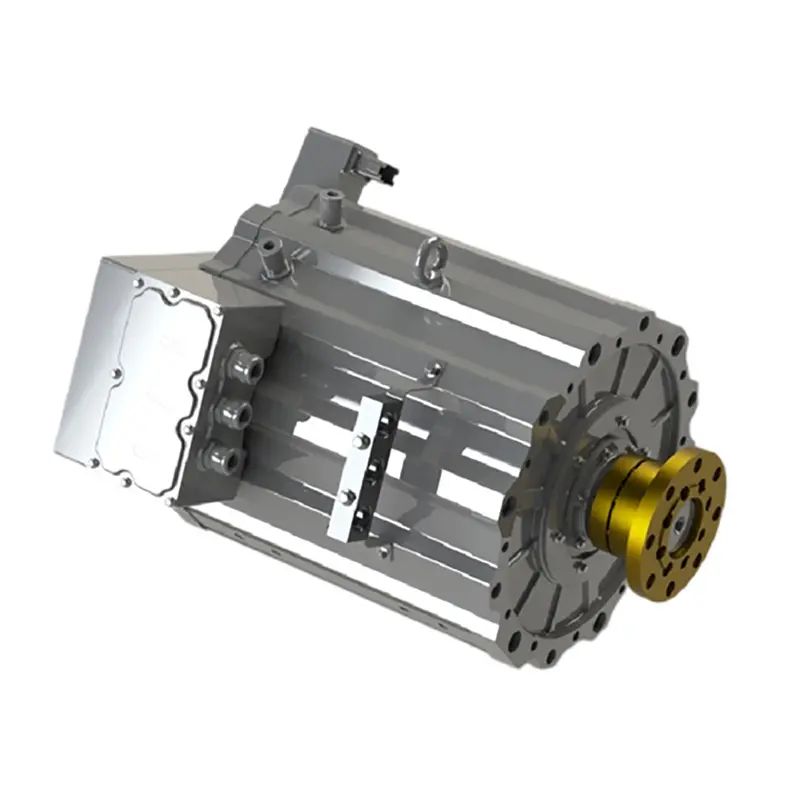

Permanent Magnet Synchronous Electric Motor

Key Features of Permanent Magnet Synchronous Electric Motors

- High Efficiency – PMSM motors offer excellent efficiency, often exceeding 90%, leading to reduced energy consumption and lower operating costs.

-

Compact & Lightweight – The use of permanent magnets allows for a smaller, lighter design without sacrificing output power.

-

High Torque Density – Delivers superior torque performance, making it ideal for demanding applications.

-

Low Maintenance – With fewer mechanical parts and no brushes, PMSM motors require minimal servicing.

-

Smooth & Quiet Operation – The synchronous design ensures low vibration and noise levels, enhancing user comfort in noise-sensitive environments.

description2

Applications of PMSM Motors

Permanent magnet synchronous electric motors are widely used across multiple industries due to their precision, reliability, and energy-saving capabilities. Common applications include:

-

Electric Vehicles (EVs) – For high efficiency, strong acceleration, and extended driving range.

-

Industrial Automation – Powering CNC machines, conveyors, and production line equipment.

-

HVAC Systems – Ensuring efficient operation of compressors, fans, and pumps.

-

Renewable Energy – Used in wind turbines and hydroelectric generators for sustainable power generation.

-

Robotics & Motion Control – Delivering precise positioning and smooth motion for advanced automation.

description2

Why Choose Our Permanent Magnet Synchronous Electric Motors?

We offer PMSM motors designed with advanced materials, precision engineering, and strict quality control to meet the demands of modern industries. Our motors provide:

-

Consistent high performance in demanding environments.

-

Customizable specifications to fit your application needs.

-

Long service life with excellent reliability.

description2

Technical Advantages of PMSM Motors

- Higher Power Factor – Reduces reactive power losses and improves system efficiency.

- Better Control Performance – Works seamlessly with modern variable frequency drives (VFDs) for precise speed and torque control.

- Energy Savings – Lower operational costs compared to induction motors over the long term.

description2