PMSM motor: The ideal choice for efficient electric vehicle driving

I. Introduction

With the global focus on carbon neutrality and the rapid upgrading of the electric vehicle (EV) industry, the demand for high-efficiency, high-performance drive motors is becoming increasingly stringent. As a core component determining EV range, power performance, and reliability, the PMSM motor has gradually become the mainstream configuration of new energy vehicles, replacing traditional motors in many high-end and mass-market models.

Since the 1970s, the development of rare earth permanent magnet materials has driven the upgrading of permanent magnet motors—relying on the stable magnetic field generated by permanent magnets, pmsm motor for EV has broken through the performance bottlenecks of traditional electrically excited motors, showing obvious advantages in energy saving, miniaturization, and precision control. This article will deeply analyze the technical characteristics, core advantages, and practical value of PMSM motors, and discuss their development prospects in the EV field.

II. Introduction to PMSM Motors and Their Role in Electric Vehicles

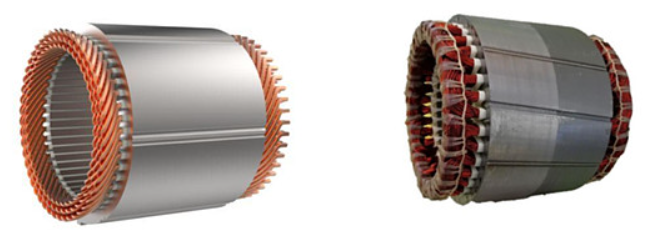

A PMSM motor is an AC motor that uses permanent magnets to establish the rotor magnetic field, realizing synchronous operation between the rotor and the stator rotating magnetic field without slip rings, brushes,s or rotor excitation windings. Unlike traditional motors, its magnetic field is provided by rare-earth permanent magnet materials (such as neodymium-iron-boron Nd2Fe14B), which have excellent magnetic properties such as high coercivity, residual magnetism, and magnetic energy product.

In electric vehicles, the pmsm motor for ev undertakes the core task of converting electrical energy into mechanical energy, directly affecting the vehicle's dynamic response, energy consumption, and driving experience.

With the maturity of vector control, direct torque control,l and power electronic device technology, PMSM motors have solved the historical problems of difficult startup and complex control, and are widely used in passenger cars, commercial vehicles,s and new energy special vehicles. From high-performance EVs pursuing fast acceleration to family cars focusing on long range, PMSM motors can be customized and adjusted to meet diverse product positioning needs.

From the perspective of development history, the first motor in the world was a permanent magnet motor, but it was once replaced by electrically excited motors due to the backward performance of permanent magnet materials. It was not until the emergence of NdFeB rare earth materials in the 1970s that the PMSM motor regained vitality and moved towards the direction of high power, high efficiency, and miniaturization. Today, leading enterprises at home and abroad have achieved breakthroughs in large-power PMSM technology, laying a solid foundation for its popularization in the EV industry.

III. The Working Principle and Technical Features of PMSM Motors

3.1 The Interaction Principle Between Permanent Magnets and Electromagnetic Fields

The core working principle ofPMSM motor is based on the electromagnetic induction and mutual excitation effect between permanent magnets and alternating current. The rotor is equipped with rare-earth permanent magnets, which generate a constant magnetic field after magnetization; the stator winding is connected to a three-phase alternating current to form a rotating magnetic field with adjustable speed and amplitude.

Under the action of electromagnetic force, the rotor is "locked" with the stator's rotating magnetic field and runs synchronously, with the rotation speed equal to the synchronous speed (no slip loss), which fundamentally improves the energy conversion efficiency.

3.2 The Efficient Energy Conversion Process

Compared with traditional electrically excited motors, pmsm motor for ev eliminates the excitation loss of rotor windings and the mechanical loss of brushes and slip rings, and the stator current only needs to provide torque current, thus significantly reducing copper loss and iron loss. In the energy conversion process, the magnetic field of permanent magnets is stable and reliable, and the energy loss is controlled at a low level—even under partial load or low-speed working conditions, it can maintain high efficiency, which is crucial for extending the range of electric vehicles.

3.3 Precise Speed and Torque Control

The precise control of the PMSM motor relies on advanced control algorithms and high-performance power electronic devices. Vector control (FOC) solves the problem of AC motor speed regulation from the principle, realizing smooth speed regulation in a wide range and fast torque response; direct torque control (DTC) simplifies the control structure, with strong robustness to parameter changes and fast dynamic response.

For electric vehicles, this means that the motor can output large torque instantly during startup and acceleration, and maintain stable operation during high-speed cruising, while achieving precise matching between speed and torque according to driving conditions, optimizing energy consumption.

In addition, the application of high-performance processors and power electronic devices has further improved the control precision and response speed of PMSM motors. General frequency converters can convert power frequency power into variable frequency power, solving the startup problem of synchronous motors and providing a reliable technical guarantee for the application of pmsm motor for ev.

IV. Advantages of PMSM Motors for Efficient Driving in Electric Vehicles

4.1 Enhance Range with High Efficiency

The full-load efficiency of PMSM motor can reach 94%-97%, which is 3-5 percentage points higher than that of traditional asynchronous motors. More importantly, it can maintain high efficiency under partial load conditions, which accounts for most of the daily driving scenarios of electric vehicles.

For EVs with limited battery capacity, higher motor efficiency directly translates into longer range—under the same battery configuration, vehicles equipped with pmsm motor for ev can increase their range by 10%-15%, effectively alleviating users' range anxiety.

4.2 Strengthen Power Performance with High Torque Density

Due to the elimination of rotor excitation windings and the adoption of high-performance rare earth permanent magnets, the PMSM motor has the characteristics of compact structure, small size, and light weight. Under the same volume and weight, its torque density is 20%-30% higher than that of asynchronous motors, which can provide stronger power output.

For electric vehicles, this means that the motor can be arranged more flexibly, and at the same time, it can output large torque at low speed, realizing fast acceleration and strong climbing performance, enhancing the driving pleasure.

4.3 Meet Diverse Needs with Wide Speed Regulation Range

With the support of vector control technology and weak magnetic speed expansion technology, pmsm motor for ev has a wide speed regulation range—low-speed, large torque, and high-speed,d constant power can be seamlessly switched. This enables electric vehicles to adapt to complex driving conditions: it can output large torque stably when starting and climbing, and maintain high efficiency and stability when cruising at high speed. Especially for built-in PMSM motors, they have excellent weak magnetic speed expansion ability, which can further expand the high-speed working range and meet the diversified speed requirements of electric vehicles.

4.4 Ensure Driving Safety with High Reliability

The PMSM motor adopts a brushless structure, eliminating the wear and failure risks of brushes and slip rings, and its service life can reach more than 15 years (matching the service life of electric vehicles). At the same time, due to the simplification of the structure, the failure rate is significantly lower than that of traditional motors.

In the design process, by optimizing the pole arc coefficient, slot width, and adopting skewed slots and other measures, the cogging torque is reduced, the vibration and noise during motor operation are minimized, and the driving comfort and safety are improved. In addition, mature thermal management technology can effectively prevent permanent magnet demagnetization caused by high temperature, ensuring stable operation under extreme working conditions.

V. Practical Application Cases of PMSM Motors in Electric Vehicles

Globally, pmsm motor for ev has become the preferred drive motor for mainstream automakers. For example, Tesla Model 3/Y adopts an interior permanent magnet synchronous motor, which realizes a balance between high efficiency and high performance—its motor efficiency reaches 97% under optimal working conditions, and the 0-100km/h acceleration time is as low as 3.3 seconds. BYD, a domestic automaker, has independently developed a blade motor, which is widely used in models such as Han and Tang.

It uses neodymium-iron-boron permanent magnet materials and optimizes the magnetic circuit design, with a torque density of more than 40N·m/kg and a maximum efficiency of 98.5%.

In the commercial vehicle field, SAIC Maxus' electric light buses and Foton's electric trucks are also equipped with customized PMSM motors, which can adapt to the working conditions of frequent start-stop and heavy load, and the energy consumption per 100 kilometers is 15%-20% lower than that of vehicles equipped with asynchronous motors.

Internationally, BMW iX3 and Mercedes-Benz EQC also use PMSM motors as the core drive component, relying on their high reliability and efficiency to enhance the market competitiveness of products.

In terms of industrial support, leading motor enterprises such as Siemens and ABB have also made important breakthroughs in pmsm motor for ev technology. Siemens developed a 1095kW six-phase PMSM motor as early as 1986, which is used for ship propulsion, with a volume reduced by nearly 60% compared with traditional DC motors. ABB's PMSM motor for ship propulsion has a maximum installed capacity of 38MW, laying a technical foundation for the application of PMSM motors in high-power scenarios.

In China, CRRC Zhuzhou has developed a 3MW high-speed permanent magnet wind power generator, and its technology has been transferred to the EV field, promoting the upgrading of domestic PMSM motors.

VI. Comparison of PMSM Motors with Other Driving Motors

6.1 Comparison with Asynchronous Induction Motors

Asynchronous induction motors (IM) have the advantages of low cost, simple structure, and strong robustness, and were once widely used in early electric vehicles. However, compared with the PMSM motor, their disadvantages are obvious: the full-load efficiency is only 90%-93%, and the efficiency drops significantly under partial load; the torque density is low, resulting in larger volume and weight; the speed regulation precision is limited by slip, and the dynamic response is slow.

For electric vehicles pursuing range and performance, pmsm motor for ev has become a more ideal choice, while asynchronous motors are only retained in a small number of low-cost models or high-power special vehicles.

6.2 Comparison with Switched Reluctance Motors

Switched Reluctance Motors (SRM) have the advantages of simple structure, low cost, and no demagnetization risk. However, they have obvious shortcomings such as large torque ripple, high noise and low efficiency, which limit their application in passenger vehicles. PMSM motor has better smoothness, lower noise, and higher efficiency, which can better meet the comfort requirements of electric vehicles.

In addition, the control precision and dynamic response of PMSM motors are far superior to SRM, making them more suitable for scenarios with high driving performance requirements. Therefore, SRM is only used in a small number of low-end electric vehicles and special equipment, while PMSM motors dominate the mainstream EV market.

VII. The Development Trends and Challenges of PMSM Motors

7.1 Development Trends

The future development of PMSM motor will focus on two directions: low cost and high performance. In terms of low cost, the research and application of non-rare earth permanent magnet materials and recycled permanent magnet materials will reduce the dependence on neodymium-iron-boron, and the optimization of design and manufacturing processeswill further reduce production costs.

In terms of high performance, the pmsm motor for ev will develop towards high speed, large torque and intelligence—by adopting silicon carbide (SiC) power devices and advanced control algorithms (such as sliding mode control, adaptive control), the efficiency and response speed will be further improved, and the integration with vehicle-mounted intelligent systems will be realized to realize adaptive adjustment according to driving habits.

In addition, the combination of simulation technology and design technology will become a key development direction. Finite element analysis software can accurately calculate motor parameters such as magnetic field distribution and cogging torque, and the field-circuit combination method can balance calculation efficiency and precision, shortening the development cycle of PMSM motors. At the same time, permanent magnet brushless DC motors (BLDCM) will be further integrated with PMSM technology, and advanced control strategies will be introduced to expand their application in household appliances and small electric vehicles.

7.2 Core Challenges

Despite the obvious advantages, the PMSM motor still faces many challenges in the EV field. First, the price of rare earth permanent magnet materials is volatile, and the supply chain is affected by policies and environmental factors, which brings cost risks to manufacturers. Second, the problem of permanent magnet demagnetization under extreme conditions has not been completely solved, requiring further optimization of thermal management and magnetic circuit design. Third, the control system is complex, and the research and development threshold of sensorless control and low-speed startup technology is high, which restricts the popularization of small and medium-sized enterprises.

In addition, the recycling and reuse technology of permanent magnet materials is not yet mature, which brings environmental pressure to the end-of-life disposal of PMSM motor for ev. Balancing performance, cost, environmental protection, and reliability has become a key issue for the sustainable development of PMSM motors.

VIII. Conclusions and Prospects

With its advantages of high efficiency, high torque density, wide speed regulation range, and high reliability, the PMSM motor has become the ideal choice for efficient driving of electric vehicles, and will further occupy the mainstream position in the EV drive motor market with the upgrading of rare earth material technology and control technology. For electric vehicle manufacturers, optimizing the design of PMSM motor for ev, reducing costs and improving reliability will be the core competitiveness to seize the market; for consumers, vehicles equipped with PMSM motors can bring better driving experience and lower use costs.

Looking forward to the future, with the breakthrough of non-rare earth permanent magnet materials, intelligent control technology, and recycling technology, the technical bottlenecks of PMSM motors will be gradually solved, and their application fields will be further expanded—from passenger cars and commercial vehicles to new energy ships, aerospace, and other high-end fields. As the core component of new energy vehicles, PMSM motor will continue to promote the transformation and upgrading of the global automotive industry, contributing to the realization of carbon neutrality goals.