How High-Power EV Charging Systems Improve Performance for Buses, Trucks and Marine EVs

1. Introduction: The Rise of High-Power EV Charging Systems

As electrification expands across commercial transportation, the demand for high-power EV charging systems has accelerated rapidly. Fleets operating electric buses, heavy trucks, and marine vessels require more than consumer-level chargers—they need industrial-grade solutions capable of supporting long duty cycles, large battery capacities, and tight operational schedules. The shift toward high-power charging is driven not only by the need for faster turnaround times but also by the growing expectation for consistent performance in harsh or demanding environments. With larger vehicles becoming a central part of global electrification strategies, choosing the right electric car battery charger is now essential for ensuring operational continuity and long-term reliability.

2. The Difference Between Standard EV Charging Systems and High-Power Industrial Solutions

Standard EV charging systems are designed for passenger vehicles with moderate power needs and predictable charging patterns. These systems typically offer lower charging rates suitable for overnight residential charging or occasional public station use. In contrast, high-power industrial charging solutions are engineered for fleets requiring fast, frequent, and energy-intensive charging. They provide significantly higher voltage and current output, enabling large battery packs to recharge quickly without compromising battery health. Industrial charging also incorporates more advanced thermal management, ruggedized components, and communication protocols tailored for commercial operations. This fundamental difference ensures that heavy-duty EVs can maintain continuous service without extended downtime.

3. Why High-Power EV Charging Systems Are Critical for Heavy-Duty Applications

Buses, trucks, and marine vessels operate under conditions that standard chargers cannot support effectively. These applications require large kilowatt-hour capacities and consistent energy delivery, especially for vehicles running long routes, heavy loads, or multi-shift operations. High-power EV charging systems reduce charging time dramatically, allowing fleets to increase vehicle availability and improve scheduling flexibility. Faster charging also supports opportunity charging during breaks or loading cycles, which is especially valuable for logistics fleets and public transportation networks. Additionally, the thermal stability and power quality provided by industrial chargers help protect batteries from accelerated degradation, contributing to longer operational life and reduced maintenance costs. Without high-power charging, many heavy-duty electrification projects simply would not be feasible.

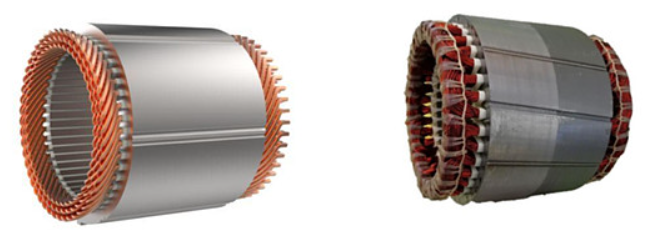

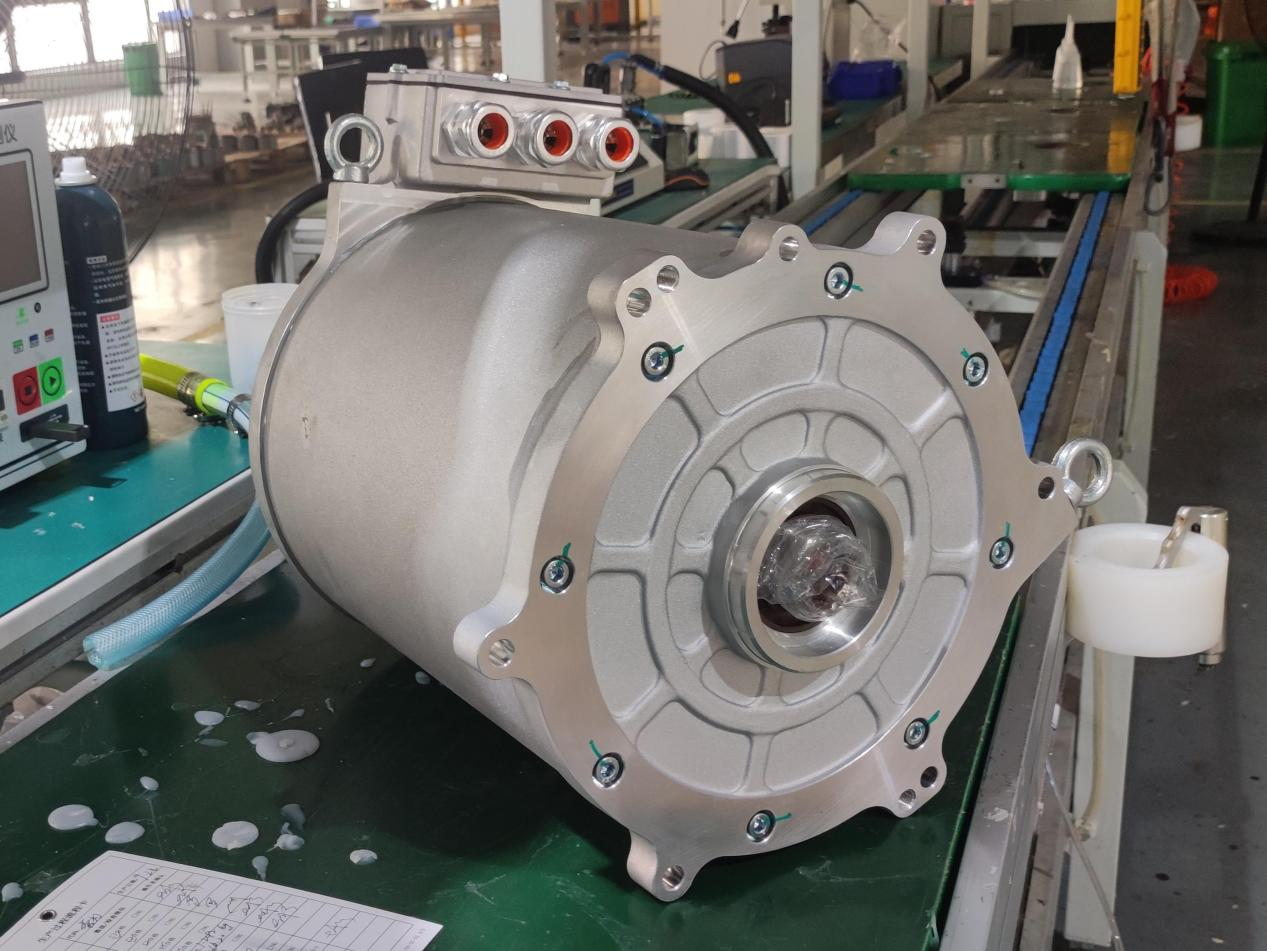

4. Key Components Required Beyond EV Charging Systems

Although the charger itself is essential, commercial electrification requires more than just high-power energy input. EV conversions or OEM development projects need a complete powertrain architecture, including a high-performance motor, sophisticated controller, and robust power management system to support large-scale charging. These components must be compatible with the vehicle’s battery type, operating voltage, load requirements, and thermal conditions. A well-designed electric propulsion system ensures smooth energy delivery, efficient regeneration, and stable performance during high-power charging cycles. When paired with the correct electric car battery charger, the powertrain determines how effectively the vehicle stores, distributes, and utilizes high-energy loads. Therefore, the charger is one part of a larger ecosystem that must be correctly engineered for optimal performance.

5. How Our Powertrain + Charging Conversion Solutions Enhance Performance

Our high-power electric motor, controller, and power system solutions are engineered to integrate seamlessly with advanced EV charging systems used in commercial applications. These components are built for continuous operation under high load, making them ideal for electric buses, industrial trucks, and marine vessels. By designing the propulsion system and charging compatibility together, we ensure stable power delivery, efficient charging behavior, and minimized thermal stress on the battery system. Our electric car battery charger solutions are tailored to meet the demands of high-capacity applications, supporting fast-charging operations without compromising safety or battery health. The result is improved acceleration, smoother power delivery, and greater operational uptime for electrified fleets.

6. Benefits of High-Power EV Charging Systems for Buses, Trucks & Vessels

High-power EV charging systems bring significant operational benefits across commercial transportation sectors. For electric buses, rapid charging reduces depot bottlenecks and allows vehicles to stay on route longer without extended charging breaks. Trucking fleets benefit from faster turnaround during logistics cycles, improving delivery efficiency and reducing idle time. In marine applications, where vessels often operate long hours and return to dock for short intervals, fast charging ensures the vessel is ready for its next deployment without delay. Additionally, high-power charging increases energy throughput while maintaining system stability, allowing operators to maximize the value of their electric powertrain investments. When paired with a durable motor and controller, fleets achieve higher performance, lower fuel costs, and significantly reduced environmental impact.

7. Integration Considerations for Fleets Using High-Power Charging

Integrating high-power charging into an existing or newly electrified fleet requires careful planning. Fleet operators must consider available grid capacity, required charging speed, and operational schedules to select the appropriate charger power rating. The compatibility between the charger, battery chemistry, and propulsion system is also critical for long-term reliability. Thermal management, both onboard and within the charging system, plays a major role in maintaining safe temperatures during high-energy charging cycles. Choosing an industrial-grade **electric car battery charger** ensures durability in demanding environments such as port terminals, bus depots, and logistics hubs. Our engineering team supports customers in evaluating system architecture, recommending optimal powertrain configurations, and ensuring seamless integration of charging infrastructure with vehicle systems.

8. Example Application Scenarios

Electrified city buses using high-power depot chargers can complete overnight fleet-wide charging and still support fast midday opportunity charging for routes that exceed initial battery capacity. Long-haul trucks operating at distribution centers can recharge rapidly during loading periods, improving daily mileage without requiring additional vehicles. Marine vessels such as ferries, workboats, or patrol craft benefit from fast high-power charging between missions, maintaining predictable schedules despite energy-intensive operations. In each scenario, the combination of a strong propulsion system and advanced EV charging systems ensures consistent performance, increased operational efficiency, and minimized downtime.

9. Why Choose Our High-Power Motor, Controller & Power System Solutions

Selecting the right partner for heavy-duty electrification is essential for long-term reliability and fleet performance. Our high-power motor, controller, and power system solutions are engineered for demanding applications and optimized to work in harmony with industrial-grade EV charging systems. Whether powering buses, heavy trucks, or marine vessels, our technology is built for robust performance, efficient energy usage, and seamless charging integration. With extensive engineering expertise and a commitment to quality, we help fleets achieve higher productivity, reduced operating costs, and a smooth transition to zero-emission operations.