For a free consultation or sample, contact us at sales@pumbaaev.com. Learn more at www.pumbaaev.com.

Multi-dimensional optimization and performance balance of electric vehicle powertrain motor selection

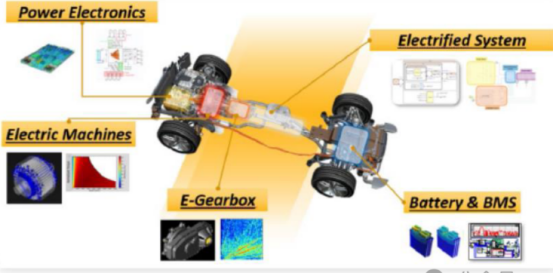

The design of electric vehicle (EV) powertrain constitutes a complex systems engineering challenge, where motor selection plays a pivotal role in determining overall vehicle performance, efficiency, and cost. Traditional motor selection methodologies typically rely on predefined powertrain architecture assumptions (e.g., gear ratios, inter-axle power distribution), while neglecting the comprehensive impact of these parameters on motor performance and the entire system. This study systematically investigates how motor-related powertrain design parameters influence motor performance, vehicle weight, cost, and efficiency through three comparative analyses. Utilizing Ansys software, we conducted case studies with a four-wheel-drive pickup truck, evaluating performance across different motor designs, gear ratio configurations, and power distribution schemes through static/dynamic vehicle requirements and EPA driving cycle testing. The findings demonstrate that systematic optimization—particularly through coordinated design of motors with gear ratios and power distribution—can significantly enhance both the overall performance and economic viability of electric vehicles.

technological superiority

1. System-level optimization methods

Traditional motor design often operates independently from other powertrain components, leading to either over-engineering or under-performance of sub-systems. The proposed system-level optimization methodology achieves optimal overall powertrain performance through iterative evaluation of component interactions including motors, gearboxes, inverters, and batteries. For instance, research demonstrates that gear ratio selection directly impacts motor feasibility and efficiency: high-speed motors (IPM-20krpm) fail to meet performance requirements at low gear ratios (3:1), while significant performance improvements are observed when adjusting the gear ratio to 10:1.

2. Flexibility of motor type and power distribution

The study compared the combined performance of permanent magnet motors (PM) with non-permanent magnet motors such as induction motors (IM) and wound-rotor synchronous motors (WRSM). Results showed that hybrid use of PM and non-PM motors can optimize both efficiency and cost. For instance, the IPM-WRSM combination demonstrated higher overall efficiency in EPA drive cycles, as WRSM outperforms PM in high-load scenarios while PM outperforms it under low-load conditions.

3. Balance between cost and performance

Through optimized design, research has revealed that not all PM motor configurations deliver optimal cost-effectiveness. For instance, while the dual PM motor configuration (IPMB-IPMB) demonstrates superior performance, it incurs higher costs. In contrast, the IPM-WRSM combination reduces costs by 3.3% with only a 1% power loss. Additionally, the choice between MOSFET and IGBT inverters significantly impacts system efficiency and cost—MOSFETs offer higher efficiency but come at a greater expense.

Key technical parameters

1. Motor performance parameters

Speed and Torque: Case A compared three IPM motors with different rated speeds (20,15, and 12 kRPM). The low-speed motor (IPM-12 kRPM) performed best at a gear ratio of 8:1, while the high-speed motor required a higher gear ratio to meet torque demands.

Efficiency and power density: PM motors are generally more efficient than non-PM motors, but cost more. For example, IPM-B (345kW) performs well in driving cycles, but costs $1,630, while WRSM (330kW) costs only $990.

2. Gear ratio effect

The selection of gear ratio directly affects the operating range and vehicle efficiency of the motor. The research found that IPM-15krpm achieved the maximum range (395.64 km) and efficiency (3.9525 km/kWh) at a gear ratio of 10:1, while IPM-12krpm performed better at a gear ratio of 8:1.

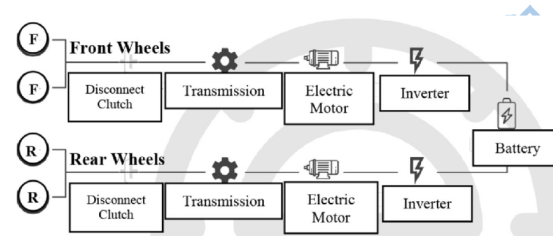

3. Power distribution strategy

The efficiency of the vehicle is further improved by optimizing the power distribution between the front and rear axle motors. For example, the IPMB-WRSM combination dynamically distributes the load to keep the IPM operating in a high-efficiency range.

4. Inverter performance

The type of inverter has a significant impact on the efficiency of the system. MOSFET inverter has lower loss than IGBT under the same current, but its cost is higher. In the optimized design, high performance scheme tends to choose MOSFET.

Industrial applications

1. Powertrain design for electric vehicles

This study provides electric vehicle manufacturers with a system-level design methodology to optimize motor selection, gear ratio configuration, and power distribution. For example, in all-wheel-drive vehicles, hybrid use of PM and non-PM motors can reduce costs while maintaining performance. Additionally, the research findings support multi-objective optimization (such as range and cost), offering data-driven decision-making support.

2. Supply chain and cost control

By analyzing motor costs (such as the proportion of PM material) and inverter selection, companies can find a balance between performance and cost. For example, the combination of medium-power PM motors (such as IPM-B) and WRSM is an economical and efficient solution.

3. Standardized testing and verification

The study uses EPA-driven cycles and static/dynamic test standards to provide a reusable evaluation framework for the industry. In the future, it can be extended to more vehicles and operating conditions (such as extreme weather or complex road conditions).

4. Technology trends

The study points out that future powertrain design needs to further integrate the collaborative optimization of motors, inverters and batteries. For example, the combination of high-voltage battery systems (e.g., 800V) and efficient motors may become a trend.

conclusion

Through system-level analysis and multi-case studies, the core position of motor selection in the design of electric vehicle powertrain is proved. It mainly includes:

• Gear ratio and motor speed should be designed in coordination to meet performance requirements;

• The hybrid use of PM and non-PM motors can optimize efficiency and cost;

• The selection of inverter (e.g., MOSFET) has a significant impact on system efficiency.

These conclusions provide important guidance for the engineering practice of electric vehicle powertrain and help the industry to achieve higher performance and lower cost electrification solutions.