Permanent Magnet Synchronous Electric Motor Driving Future Efficiency

1. Introduction

The global transition toward energy efficiency, electrification, and automation has brought electric motors into the spotlight. Among the wide variety of motor technologies available, the Permanent Magnet Synchronous Motor (PMSM) stands out as one of the most efficient, reliable, and high-performance solutions. PMSMs are used across industries ranging from industrial automation and robotics to automotive and renewable energy.

Unlike traditional induction motors, PMSMs utilize permanent magnets embedded in the rotor, eliminating the need for external excitation and significantly reducing energy losses. This design enables superior efficiency, higher power density, and precise speed control, making PMSMs a core technology for the future of sustainable and intelligent systems.

This article explores PMSMs in depth—from their working principles and advantages to industry applications, current trends, and the challenges shaping their future.

2. Understanding Permanent Magnet Synchronous Electric Motor

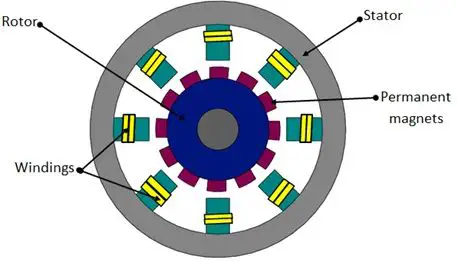

A Permanent Magnet Synchronous Motor is a type of synchronous motor where the rotor is embedded with permanent magnets. These magnets generate a constant magnetic field, which interacts with the stator’s rotating magnetic field produced by alternating current (AC). The rotor and stator fields lock in synchrony, meaning the motor runs at the same speed as the applied frequency.

Key characteristics include:

- Synchronous operation: Unlike induction motors, which have slip between rotor and stator speed, PMSMs operate without slip, providing exact speed control.

- Permanent magnets: The rotor uses high-performance materials such as neodymium-iron-boron (NdFeB) magnets to deliver strong and stable magnetic fields.

Types of PMSM:

- Surface-mounted PMSM (SPMSM) – Magnets are placed on the rotor surface, providing simple construction and high efficiency.

- Interior PMSM (IPMSM) – Magnets are buried within the rotor, offering higher torque density, improved field weakening, and robustness.

By combining synchronous operation with permanent magnet excitation, PMSMs provide unmatched control and efficiency in demanding applications.

3. Advantages of Permanent Magnet Synchronous Electric Motor

PMSMs offer a suite of technical advantages that make them increasingly preferred across industries:

3.1 High Efficiency

PMSMs eliminate rotor copper losses since no current is required for rotor excitation. This design yields superior efficiency, especially at partial load, making them a sustainable solution for continuous operation.

3.2 High Power Density

With permanent magnets providing a strong flux, PMSMs achieve high torque and power output in a compact size. This feature is especially valuable in applications like electric vehicles (EVs) and aerospace, where space and weight are critical.

3.3 Precision and Control

The synchronous nature of PMSMs allows precise control of speed and position. When combined with advanced control algorithms such as vector control or direct torque control (DTC), PMSMs deliver excellent dynamic performance.

3.4 Reliability and Durability

With fewer losses, lower heat generation, and robust construction, PMSMs exhibit long service life and stable performance under demanding conditions.

3.5 Low Noise and Smooth Operation

The sinusoidal back electromotive force (EMF) and synchronous speed operation ensure quiet, smooth, and vibration-free motion—important in robotics, automation, and household appliances.

3.6 Wide Speed Range

Especially in the case of IPMSMs, the motor can operate efficiently across a wide range of speeds, including high-speed regions enabled by field weakening.

These advantages establish PMSMs as the gold standard in modern motion systems.

4. Applications Across Industries

The versatility of PMSMs enables adoption in a wide spectrum of industries.

Industrial Automation

- Robotics: PMSMs provide precise motion, high torque density, and responsiveness—critical for industrial robots, collaborative robots (cobots), and automated assembly systems.

- CNC Machines: In machining, PMSMs deliver stable speed and torque, ensuring accuracy in cutting, drilling, and milling operations.

- Material Handling: Conveyor systems, automated guided vehicles (AGVs), and lifting equipment benefit from PMSM’s efficiency and control.

Renewable Energy

- Wind Power: PMSMs are widely adopted in direct-drive wind turbines due to their reliability, low maintenance, and ability to operate at variable speeds.

- Hydropower and Wave Energy: Compact PMSMs are integrated into hydrokinetic and marine energy converters to harvest power efficiently.

Household Appliances

Washing machines, refrigerators, and air conditioners increasingly use PMSMs for quieter operation, higher efficiency, and extended lifespan.

Aerospace and Defense

Aircraft systems, drones, and satellites employ PMSMs for weight-sensitive and performance-critical functions. The compactness and high torque-to-weight ratio of PMSMs are unmatched.

Medical Devices

Precision equipment such as MRI machines, ventilators, and surgical robots rely on PMSMs for accuracy, low noise, and reliability.

5. Permanent Magnet Synchronous Electric Motor in Electric Vehicles

The automotive industry is one of the largest drivers of PMSM adoption. As electric mobility accelerates, PMSMs have become the motor of choice for many leading EV manufacturers.

5.1 Why PMSMs in EVs?

- Efficiency translates to longer driving range – Every percentage of efficiency saved contributes directly to range extension.

- Compactness – PMSMs fit seamlessly in limited vehicle spaces while delivering high torque.

- Instant Torque – Permanent magnets allow quick response and strong acceleration.

- Thermal Management – Reduced rotor losses keep temperatures lower, improving reliability.

5.2 Typical Applications in EVs

- Traction Motors – Core propulsion systems in passenger cars, buses, and trucks.

- E-Axle Systems – Integrated drive units combining PMSM, power electronics, and gearbox into a compact solution.

- Auxiliary Systems – Power steering, pumps, and compressors benefit from PMSMs’ efficiency and controllability.

5.3 Case Studies

- Tesla, BMW, and Toyota have widely implemented PMSMs in their EV lineups, each leveraging variations in magnet placement and cooling techniques to optimize performance.

- Commercial Vehicles such as electric trucks and buses increasingly integrate PMSMs to meet strict emission and efficiency regulations.

6. Industry Trends Driving the Growth of PMSM

The global demand for PMSMs is expanding rapidly due to several converging trends:

6.1 Electrification of Transportation

The push for sustainable mobility and regulations to phase out internal combustion engines are driving PMSM adoption in EVs, trains, and even marine transport.

6.2 Industry 4.0 and Smart Manufacturing

Automation, robotics, and digitalized factories require motors with high precision, connectivity, and efficiency—all of which PMSMs provide.

6.3 Renewable Energy Integration

As renewable energy grows, PMSMs are increasingly used in wind, hydro, and distributed energy systems to enhance performance and reduce maintenance.

6.4 Advances in Magnet Technology

Innovations in rare-earth magnet materials, as well as magnet-free PMSM alternatives (ferrite-based or hybrid designs), are enhancing availability and sustainability.

6.5 Control System Innovations

Advances in motor control electronics, sensors, and AI-driven optimization are making PMSMs more intelligent, efficient, and adaptable to diverse applications.

6.6 Sustainability and Energy Efficiency Regulations

Global initiatives such as the EU’s Ecodesign Directive and U.S. Department of Energy standards are pushing industries to adopt PMSMs for compliance.

7. Challenges and Future Outlook

While PMSMs lead in efficiency and performance, several challenges remain:

7.1 Dependence on Rare Earth Materials

The reliance on rare-earth magnets like neodymium and dysprosium raises concerns over supply chain stability and environmental sustainability. This challenge has accelerated research into rare-earth-free alternatives.

7.2 Thermal Management

At high power densities, effective cooling becomes essential. Future PMSM designs are focusing on advanced liquid cooling systems and thermal modeling.

7.3 Demagnetization Risks

High operating temperatures or excessive currents can demagnetize permanent magnets. Engineers are developing magnet coatings, improved rotor structures, and fault-tolerant designs to address this risk.

7.4 Competition from Emerging Motor Technologies

Alternatives such as switched reluctance motors (SRMs) and induction motors continue to evolve. However, PMSMs maintain strong competitive advantages in efficiency and control.

7.5 Future Directions

- Hybrid motor topologies combining PMSM with reluctance principles for improved performance.

- Digital twins and AI monitoring for predictive maintenance and optimization.

- Integration with wide-bandgap semiconductors (SiC, GaN) in drives for higher efficiency and faster switching.

- Expansion into new sectors such as urban air mobility (UAM), marine electrification, and precision agriculture.

8. Conclusion

The Permanent Magnet Synchronous Motor is a cornerstone of modern electrification and automation. Its high efficiency, compactness, precision, and versatility make it indispensable in applications ranging from industrial automation and robotics to renewable energy and electric vehicles.

As industries accelerate toward sustainability and digitalization, PMSMs will continue to play a pivotal role. While challenges such as rare-earth dependency and thermal management exist, ongoing innovations in materials, design, and control systems are ensuring PMSMs remain at the forefront of motor technology.

In the journey toward a smarter, cleaner, and more efficient world, the Permanent Magnet Synchronous Motor is not just a component—it is a driving force of the future.