The operational data reveals the challenges and opportunities of truck electrification

Preface

Truck electrification remains a critical challenge for achieving zero-emission transportation. Based on annual operational data from 61,598 electric trucks in China, this study reveals that electric truck adoption rates are significantly lower than diesel vehicles. Only 23% of delivery trucks and 30% of semi-trailers can fully replace diesel counterparts one-to-one. On average, 3.8 electric delivery trucks or 3.6 electric semi-trailers are required to replace one diesel vehicle. For replaceable diesel vehicles, electric trucks can reduce costs by 15%-54% and lower lifecycle carbon emissions by 1%-49%. By optimizing usage patterns, enhancing battery energy density, and improving charging infrastructure, electrification feasibility can be substantially improved. By 2030, China's electric trucks are projected to achieve lower carbon emissions than diesel vehicles.

Reducing carbon dioxide emissions in transportation is crucial for achieving carbon neutrality, with heavy-duty vehicles accounting for approximately 30% of global CO2 emissions from road transport. Fleet electrification has been recognized as a key solution, with regions like the United States and Europe having established targets to accelerate the electrification of heavy-duty trucks. In China, however, electric truck (ET) sales growth has been sluggish, representing only 1.5% of newly registered trucks in 2021 – significantly lower than electric vehicles and buses. Market adoption of ETs remains cautious, primarily due to range limitations, insufficient battery capacity, and inadequate charging infrastructure. The lifecycle carbon reduction potential of ETs remains uncertain. This study utilizes annual operational data from over 60,000 ETs in China, proposing "priority group ratios" and "replacement rates" as indicators of electrification feasibility to evaluate ETs' actual cost-effectiveness and emission reduction benefits. The research demonstrates that optimizing usage patterns, improving battery technology, and enhancing charging facilities can substantially enhance the cost-effectiveness and emission reduction potential of ETs, providing valuable insights for future truck electrification initiatives.

Difference in usage patterns of electric and diesel trucks

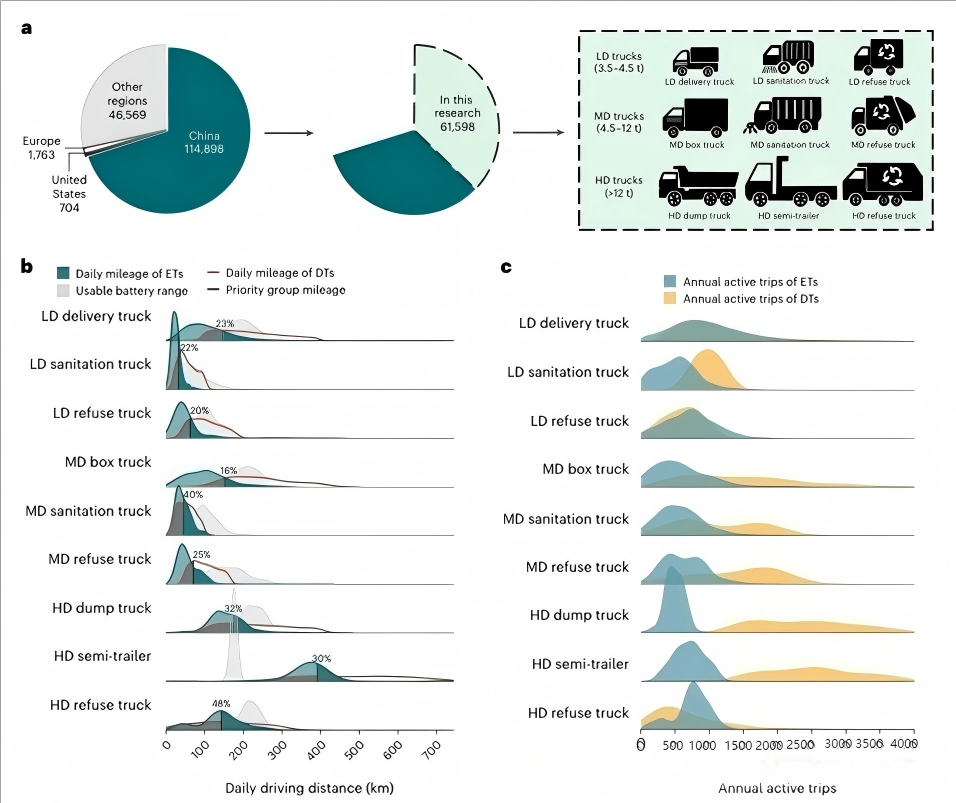

This study, based on large-scale operational data analysis of 61,598 electric trucks (ETs) and 55,411 diesel trucks in China in 2021, reveals that electric trucks demonstrate significantly lower usage intensity compared to their diesel counterparts. Most electric vehicles achieve only 42%-75% of the daily mileage recorded by diesel trucks (Figure 1), with many failing to fully utilize their battery capacity. Key constraints include limited battery capacity, range anxiety, and differences in task allocation. While some heavy-duty electric trucks mitigate range issues through frequent charging, their overall active trips remain fewer than those of diesel vehicles. The research indicates that approximately 16%-48% of diesel trucks could be replaced one-to-one by electric alternatives, particularly light-duty delivery trucks at 23% and heavy-duty semi-trailers at 30%.

Figure 1. Vehicle stock and usage patterns of electric truck fleets

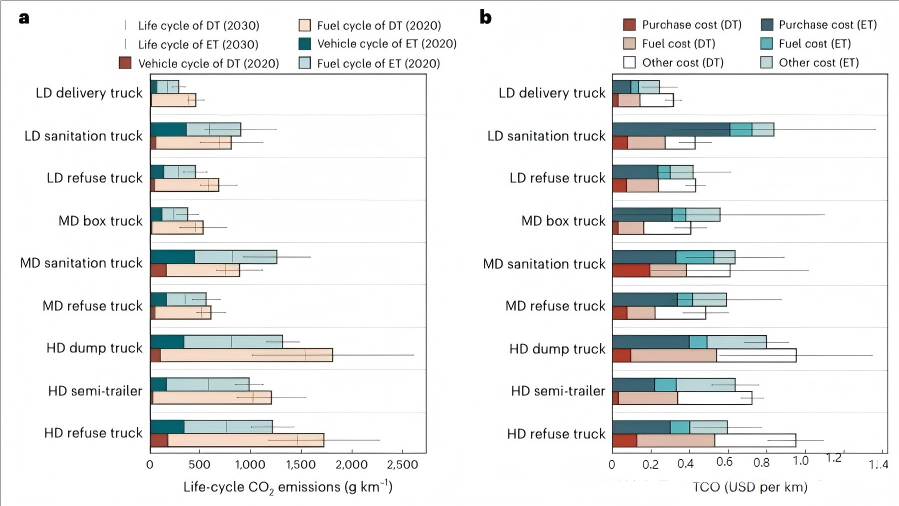

Emission and cost comparisons between individual electric and diesel trucks

Cost and carbon emissions are key metrics for evaluating the effectiveness of truck electrification. Electric trucks demonstrate significant CO2 reduction from wheel to wheel, with lifecycle emission reductions ranging between 8% and 37% due to high battery production emissions and limited driving range (Figure 2). As China's power supply becomes cleaner after 2030, most electric trucks (ETs) are expected to achieve emission reductions of 70% to 91%. In terms of cost, the total cost of ownership (TCO) for five categories of electric trucks has already surpassed that of diesel vehicles, with savings ranging from 12% to 37%. Priority group electric trucks stand out particularly, achieving a 15% to 54% reduction in TCO and 1% to 49% decrease in CO2 emissions through their high usage intensity and lower fuel costs.

Figure 2. Life cycle CO2 emissions and total cost of ownership of electric trucks and diesel trucks per vehicle

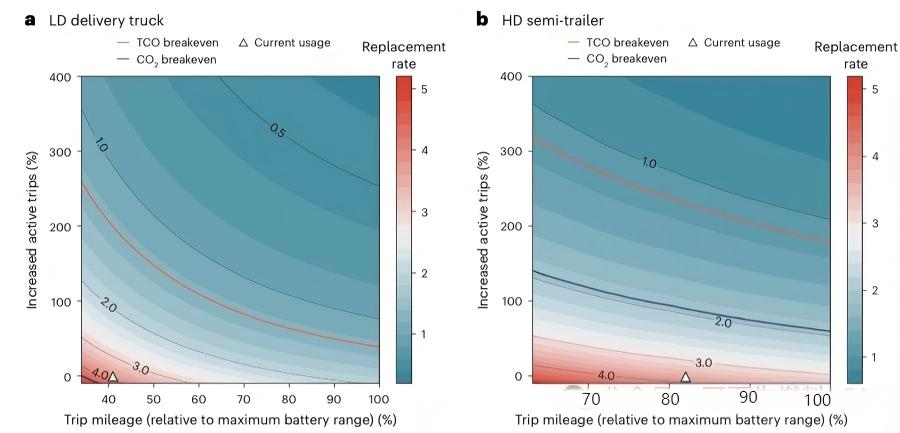

Enhancing fleet electrification effect by optimizing usage

Research indicates that the "one-to-one" replacement of diesel trucks with electric vehicles (ETs) is only viable for a limited number of vehicles. Under current usage patterns, it typically requires replacing one diesel truck with 3.8 electric delivery trucks or 3.6 electric semi-trailers, resulting in most ET fleets losing cost or lifecycle CO2 advantages (Figure 3). Optimizing usage can enhance electrification effectiveness. For instance, increasing battery utilization to 85% can boost the one-to-one replacement rate beyond 49% for most fleets, significantly reducing replacement ratios. The replacement rate for light-duty delivery trucks, for example, drops from 3.8 to 2.0 while achieving total cost of ownership (TCO) and carbon dioxide balance. Increasing active trips further improves the feasibility of electric trucks. Optimization potential for heavy-duty electric semi-trailers remains limited, requiring technological advancements like higher energy-density batteries to deliver better cost-effectiveness and emission reduction benefits.

Figure 3. Replacement rate of the fleet using normalization

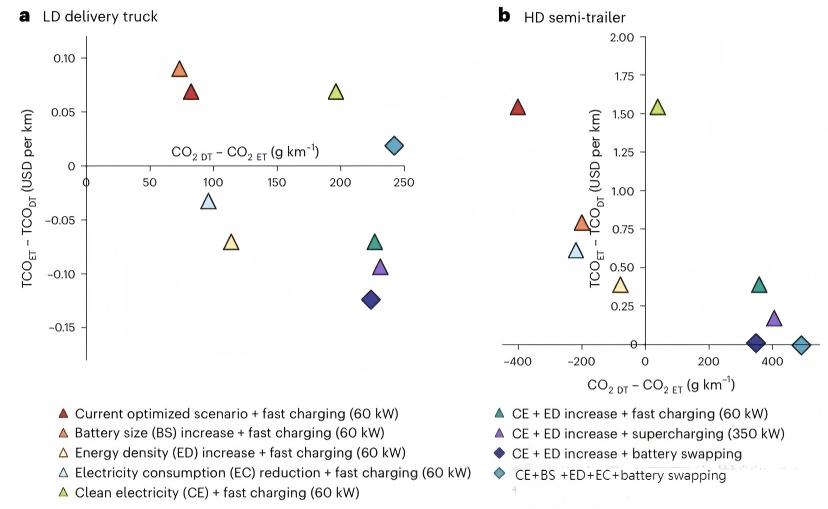

Improving truck fleet electrification benefits in the future

The optimization demonstrates the potential of current electric trucks (ETs) while highlighting the critical importance of technological advancements, particularly in battery and charging systems. By increasing battery energy density to 220 Wh/kg, the priority group ratio can exceed 70% across all fleets. For heavy-duty semi-trailers, this ratio has been boosted from 36% to 87%, significantly reducing replacement frequency while lowering total ownership costs and lifecycle CO2 emissions

(Figure 4). For low-demand fleets such as garbage trucks, battery improvements yield limited benefits. Under current technology, increasing battery capacity enhances range but requires trade-offs in payload reduction. Heavy-duty semi-trailers achieve 11% CO2 reduction and 25% cost savings by increasing battery capacity by 50% while reducing payload by 7%. Further cutting power consumption by 25% through battery swapping could enable future heavy-duty semi-trailers to achieve cost parity with diesel vehicles. Adopting sustainable electricity is key to reducing lifecycle CO2 emissions for electric vehicles, with most fleets achieving significant reductions. Future strategies should adopt differentiated improvement approaches tailored to fleet characteristics to maximize co-benefits in total cost of ownership (TCO) and carbon reduction.

Figure 4. Future electrification effects of electric trucks under different scenarios

Summary

Through life cycle modeling and sensitivity analysis, this study reveals that reducing power consumption by 10% can lower the total cost of ownership (TCO) of electric trucks (ETs) by 1.2%-3.1% and decrease CO₂ emissions by 4.9%-7.6%. While battery degradation significantly increases TCO and emissions, its impact remains less impactful than power optimization. Low operational efficiency continues to be the primary barrier to electrification, making improved utilization rates crucial. Priority group analysis demonstrates that high-mileage ETs can achieve dual benefits in both cost reduction and emission reduction. Policy incentives play a vital role in promoting ET adoption, as seen in California's HVIP program that covers 80% of purchase price differences while supporting Tesla Semi's economic viability in long-haul transportation. China needs to further invest in infrastructure to address range anxiety and task allocation challenges. The research underscores the importance of big data in electrification decision-making, with refined analysis aiding policy optimization. Future technological advancements and clean energy integration will substantially boost ET adoption rates, paving a viable path for low-carbon transition.