PUMBAA Unveils Latest Electric Conversion Solutions for 5T Loaders at Qingdao Port, Setting a New Industry Standard

Project Name: Electrification conversion of 5T loader

Project location: Qingdao Port, China

Application: Electrification of port machinery (cranes, forklifts, wheel loaders, car tractors, container trucks)

Crane

Car tractors

Wheel loaders

Container trucks

Forklifts

Electrification of mining machinery (excavators, bulldozers, motor graders, loaders, dump trucks,heavy-duty mining trucks)

Motor graders

Excavators

loaders

Bulldozers

Dump trucks

1. Background of 5T electric loader electrification conversion project

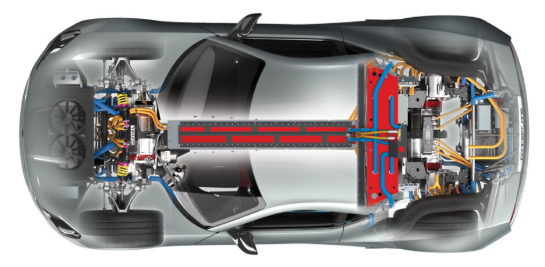

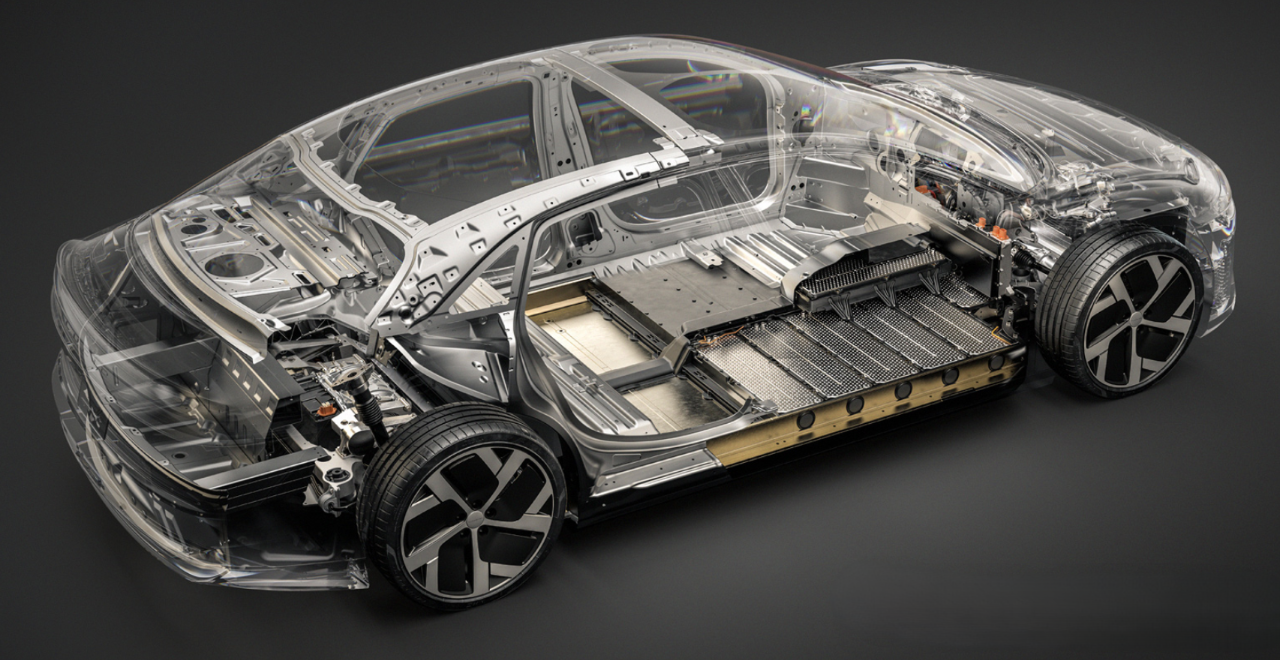

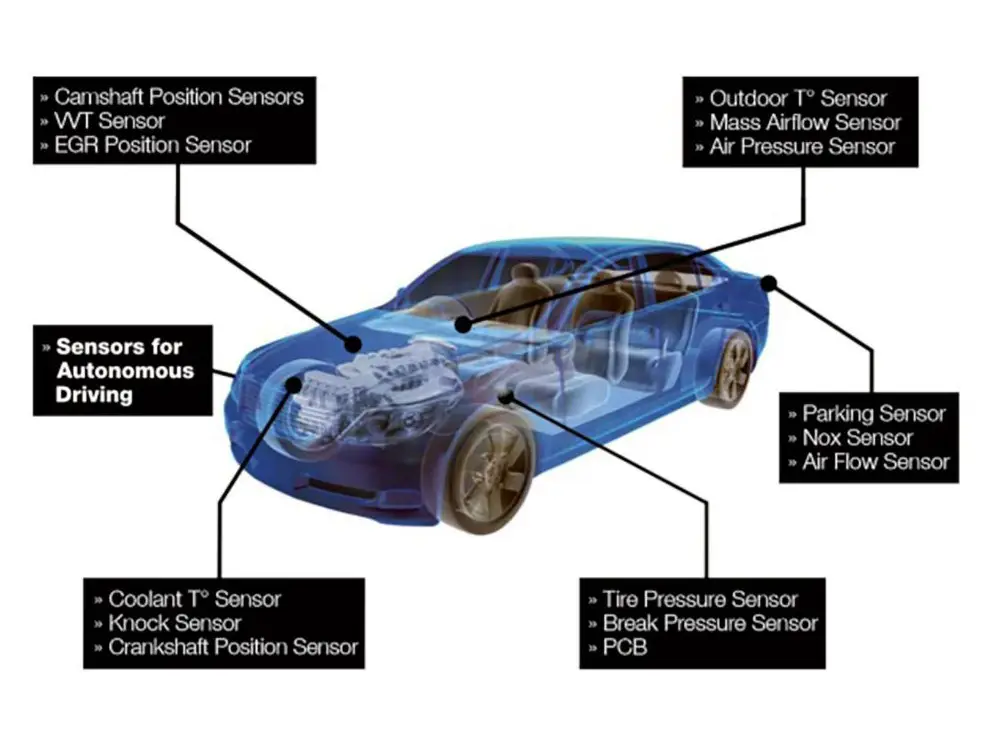

The customer of this project plans to convert a conventional fuel loader into an electric loader. Pumbaa's products cover all electric vehicle system development specialties such as motor and controller integration, vehicle controller software and hardware, power battery integration, high-voltage system integration, etc., and have the ability to develop electric vehicle three-electric systems. Pumbaa's engineers are all from mainstream automotive OEMs, with rich development experience and familiarity with the development process. Pumbaa can provide a complete retrofit solution and provide corresponding products.

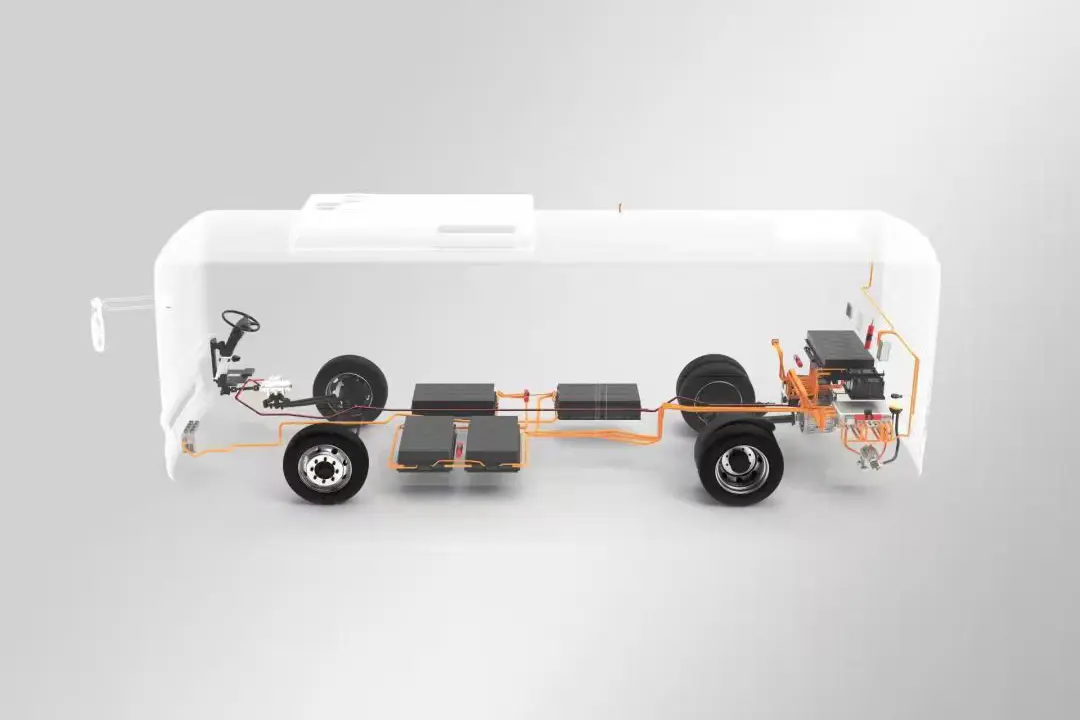

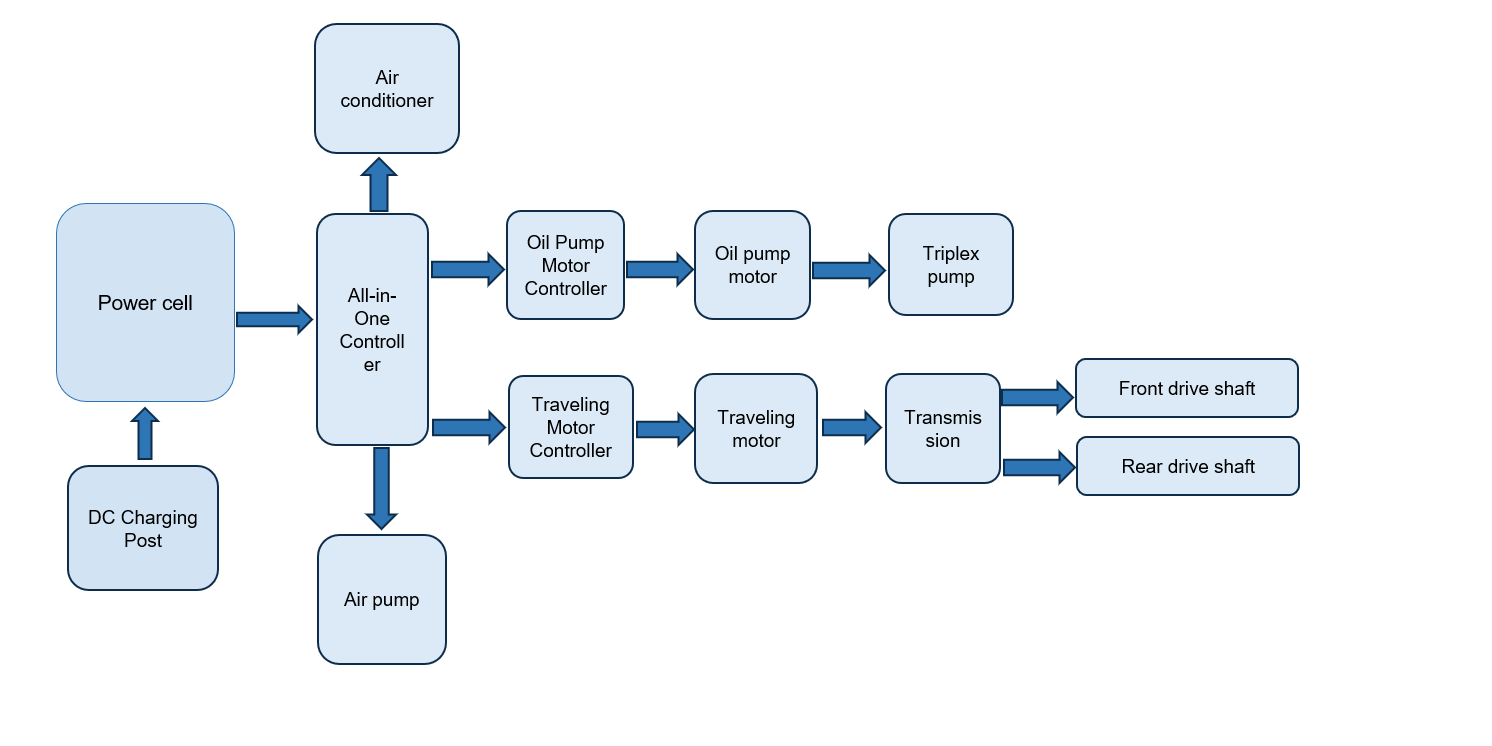

2. 5T electric loader electrification conversion system scheme

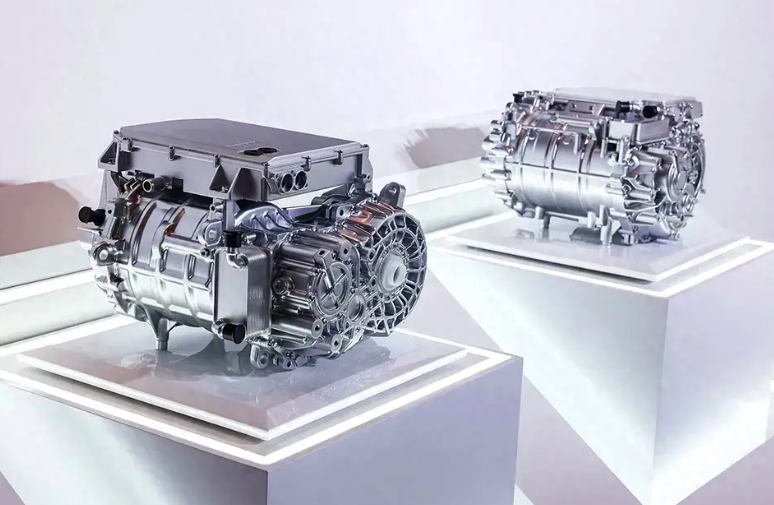

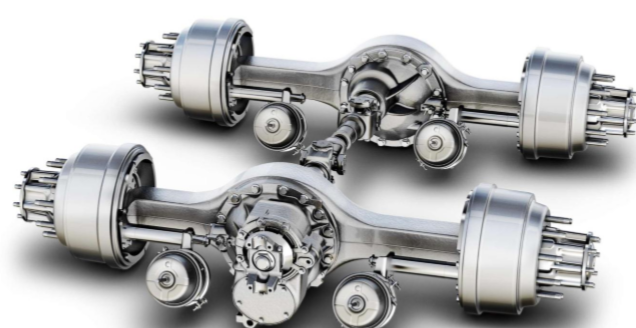

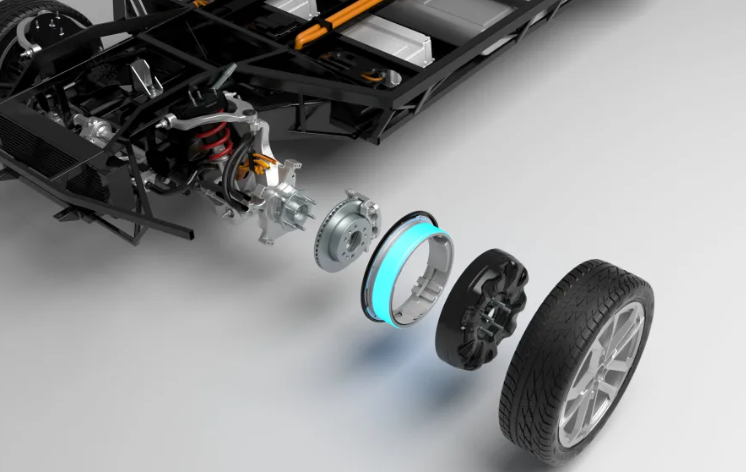

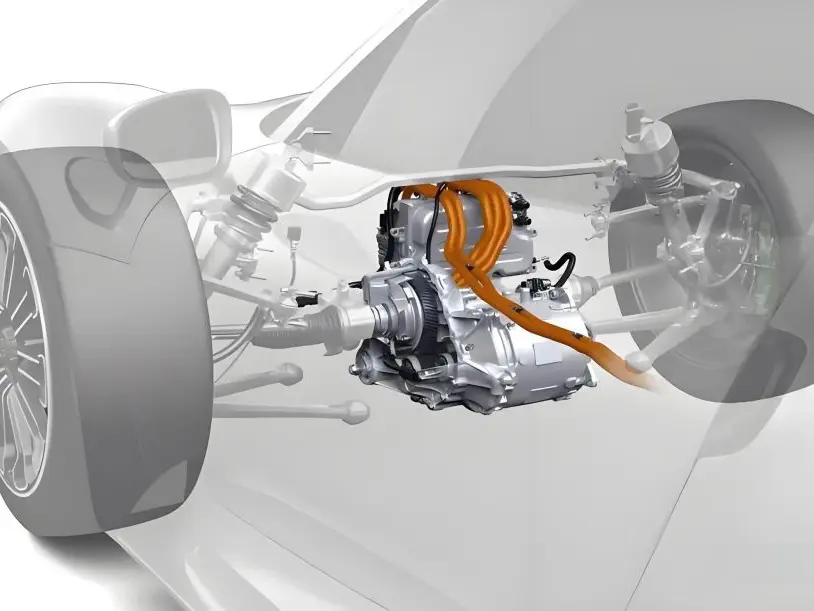

The travel system consists of a single motor and a gearbox, which is connected to the front and rear axles by two drive shafts.

It integrates the drive motor, automatic transmission and drive axle to achieve a compact structure, smoother drive, improved transmission efficiency and space saving.

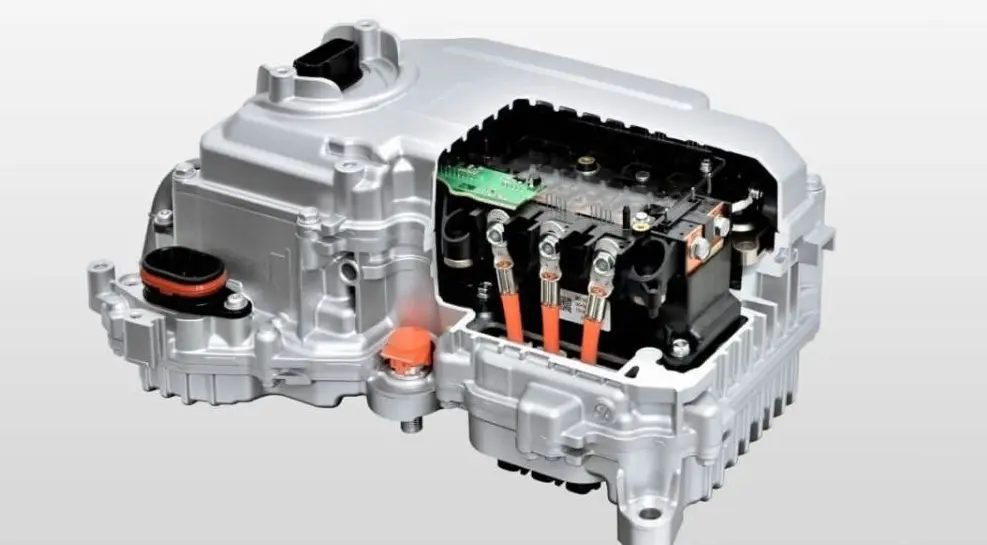

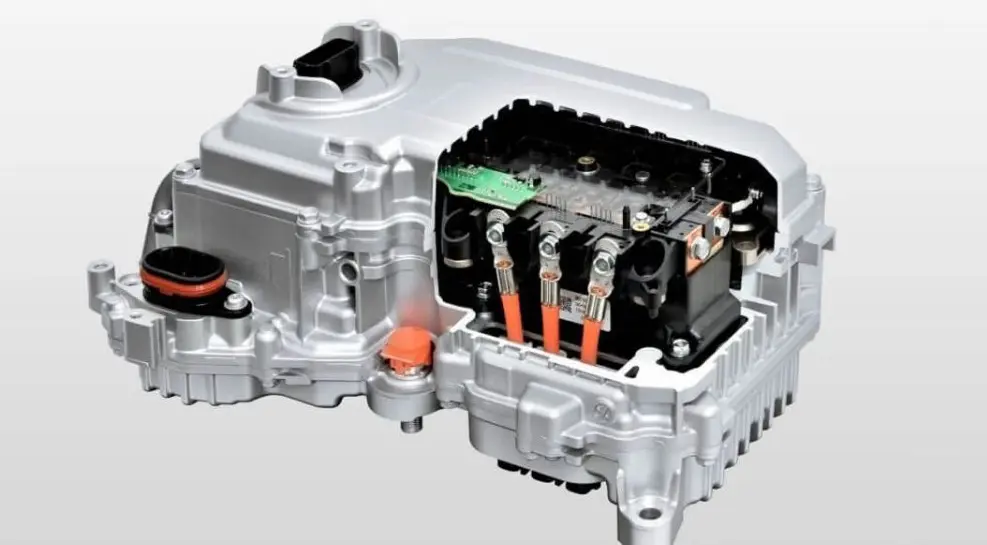

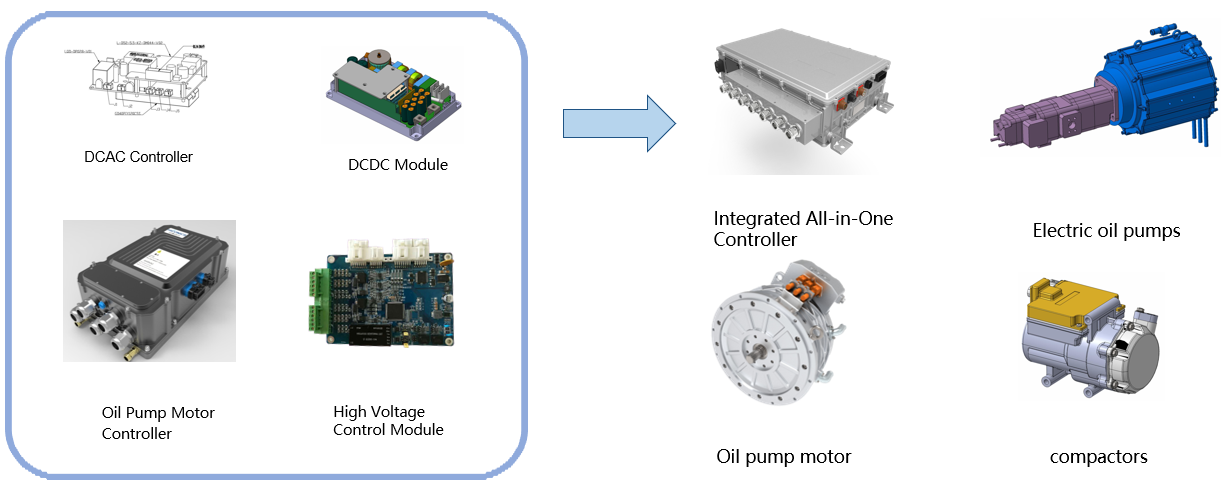

The oil pump system includes an electric oil pump, All-in-one integrated controller,Oil pump motor,Compressor.

3. 5T electric loader electrification conversion supply list

|

Pseudolaric acid |

Quantities |

Parameters |

Flat |

|

Traveling-Motor Controller |

1 |

140kW/280kW |

Piece |

|

Traveling-Motor |

1 |

3100rpm/2800NM |

Piece |

|

Traveling-Transmission |

1 |

2200rpm/2000NM |

Piece |

|

Triplex oil pump |

1 |

2100/2080/0010 |

Set |

|

Oil pump-motor |

1 |

100/146kW |

Piece |

|

Integrated All-in-One Controller |

1 |

MCU :80/150kW DCDC:3kW High-voltage Distribution DCAC:5.5kW |

Piece |

|

Vehicle Controller |

1 |

6V~36V |

Piece |

|

DC Charging Post |

1 |

240kW |

Piece |

|

Air pump |

1 |

Oil-free air pumps |

Piece |

4. 5T electric loader electrification conversion process and test data

The electric loader project has completed the trial production of a three-wheeled prototype. The functions meet the design requirements, and in the performance comparison experiment with the fuel loader, the traction force, the rising force, the three items and the time are significantly better than the fuel loader. Operating costs will be significantly reduced.

The first round of trial production : functional prototype

The second round of trial production: Engineering prototypes

The third round of trial production: Small-scale prototypes

The digital model drawings of the parts have been finalized

The system software has been frozen to meet the requirements for mass production

The state of the whole machine meets the requirements of the delivery customer

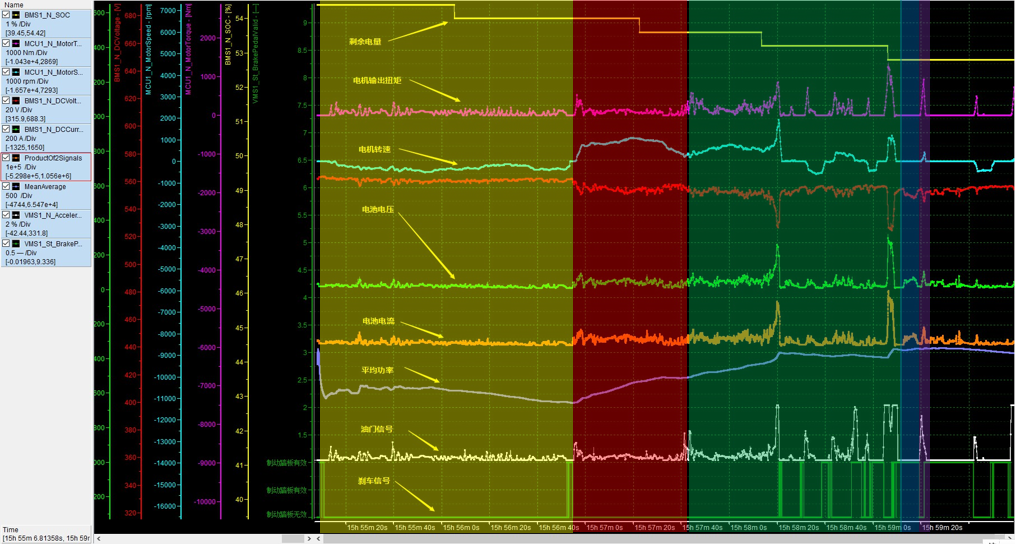

The modified electric loader has completed multiple rounds of multi-condition performance experiments, and the operation data of the electric loader has been calculated and analyzed by CANape data acquisition and typical working conditions, and the test data are as follows:

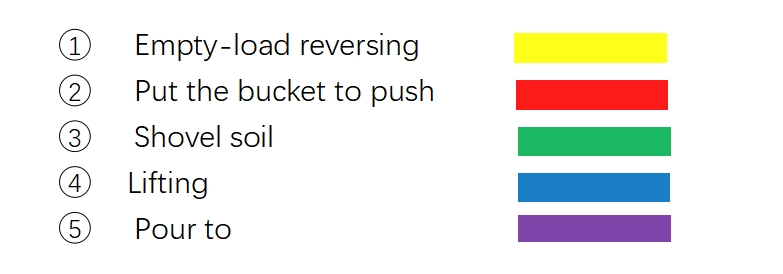

Typical duty cycles were selected for the performance test:

They are shaded by color in the image on the left.

The duty cycle vehicle peak power: 172kW;

Average power: 39.75kW;

According to the calculation of the vehicle with a charge of 163kWh and a discharge depth of 90%, the vehicle can run for 4.1 hours when fully charged.

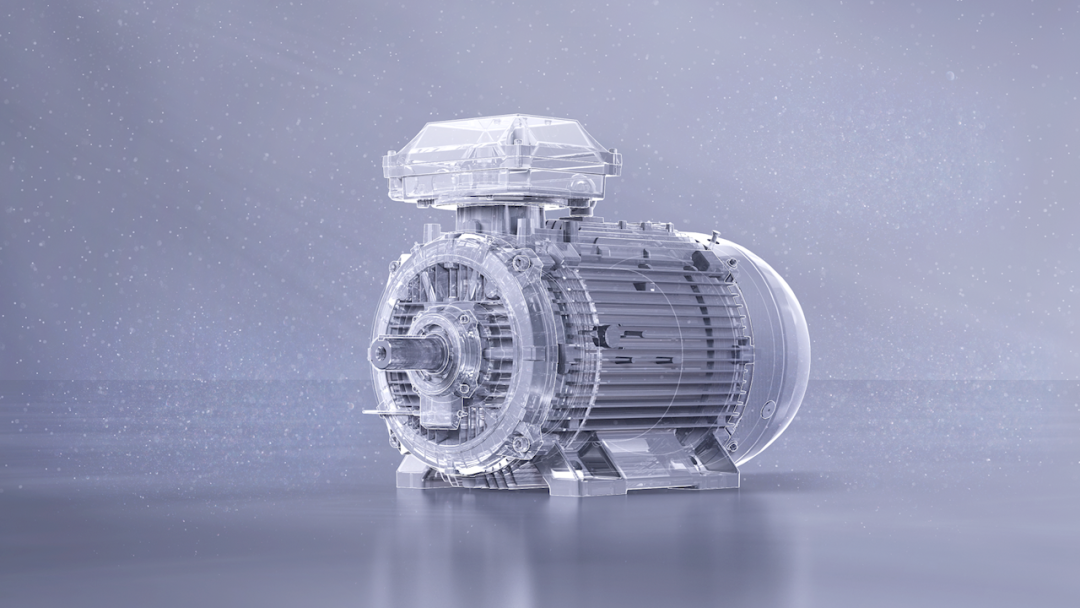

At the heart of this transformation is the PUMBAA Permanent Magnet Synchronous Motor (PMSM) Gen5 PML180, an advanced propulsion system designed specifically for electric vehicle drives. Engineered for efficiency, reliability, and performance, this motor ensures the loader delivers superior torque, smooth operation, and reduced energy consumption.

By replacing traditional combustion engines with our PMSM technology, we’ve not only reduced emissions but also enhanced operational efficiency, setting a benchmark in port machinery electrification. This milestone project reinforces PUMBAA’s position as a leader in sustainable drivetrain solutions for the global logistics and transportation sector.

Key Highlights:

- Enhanced energy efficiency and zero-emissions operation.

- Superior performance tailored to rigorous port applications.

- Demonstrates scalability for electrifying other port equipment such as cranes, forklifts, car tractors, and container trucks.

This electric loader can also be widely used in mining areas, open-pit coal mines, ports and other working conditions. It can realize energy saving and emission reduction in the whole process of pure electric and zero-emission operation in multiple fields, reduce costs and increase efficiency, and bring users the "double superposition" of environmental protection and economic benefits, creating new momentum for business development! PUMBAA works with you to promote the green and intelligent transformation of industrial scenarios and build a sustainable future together.