PUMBAA Launches Newest 20T Diesel Excavator Electric Conversion Solution in Hebei, China

Project Name: 20T diesel excavator converted to electric excavator

Project Location: Hebei.China

Application scenario: electrification of construction machinery

20T diesel excavator conversion electric excavator project transformation background:

An Equipment rental company in Hebei.China has partnered with PUMBAA to electrify its construction machinery. The customer was trying to convert their excavator diesel vehicle from traditional fuel power to electric drive. They commissioned PUMBAA to supply the motors and controllers for the job, as well as the rest of the package. Ultimately, PUMBAA delivered the powertrain system design and installation, effectively reducing vehicle operating costs compared to the standard fuel version.

Scope of application:

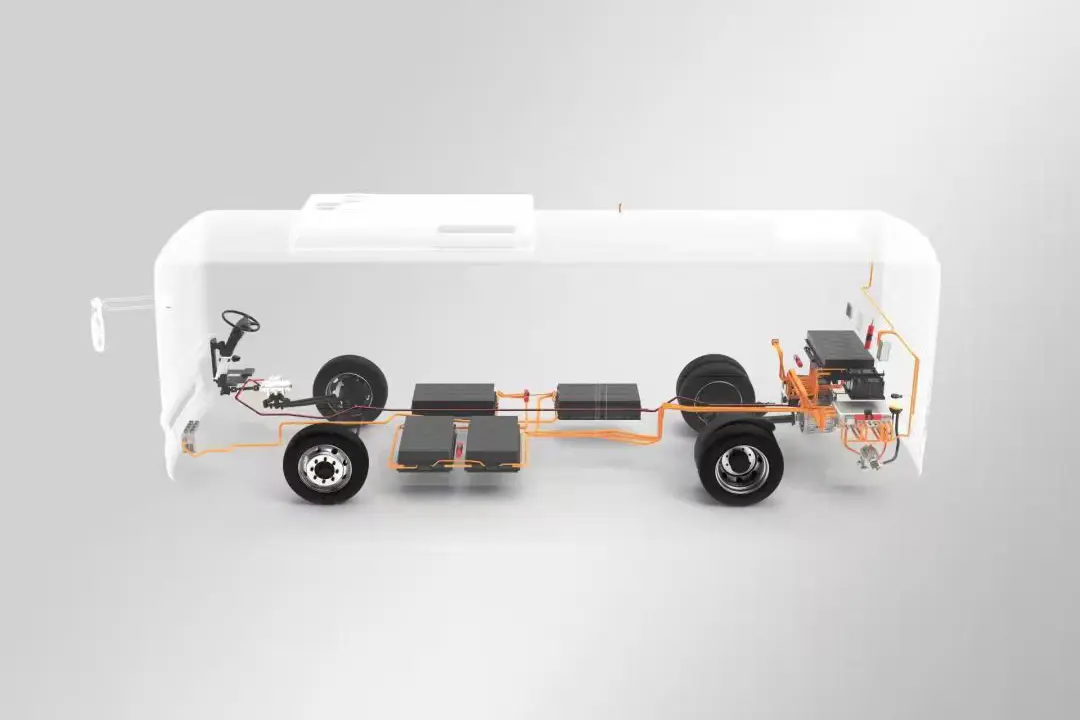

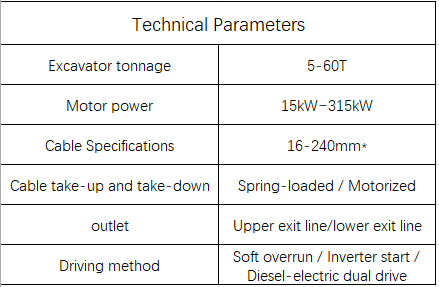

This scheme is suitable for all kinds of diesel-driven large machinery, such as excavators, loaders, road rollers, etc., and has a wide range of applications. At the same time, for other types of mobile devices, such as vehicles and ships, this scheme can also provide some reference and reference.

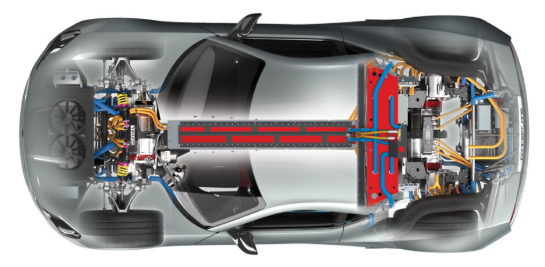

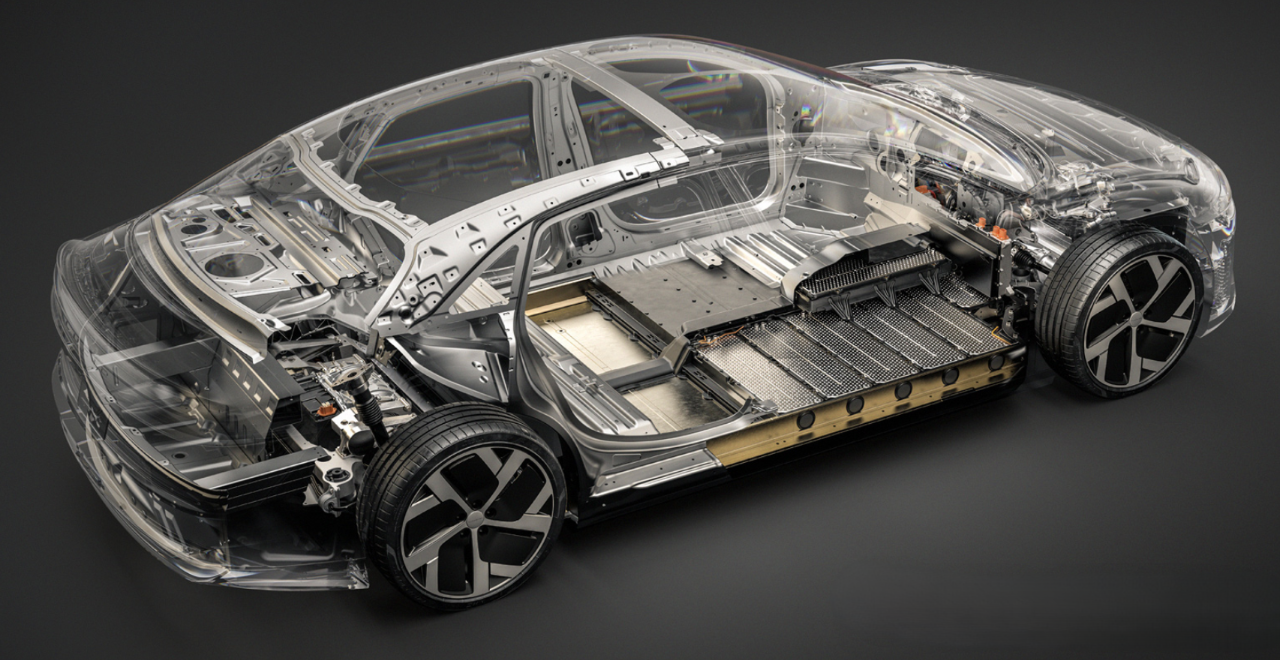

20T diesel excavator electrification conversion system scheme:

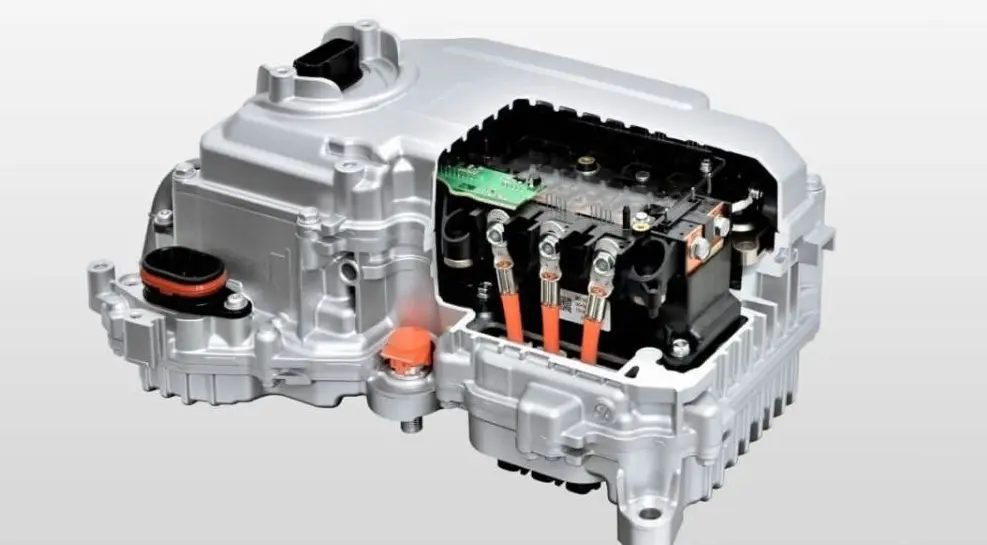

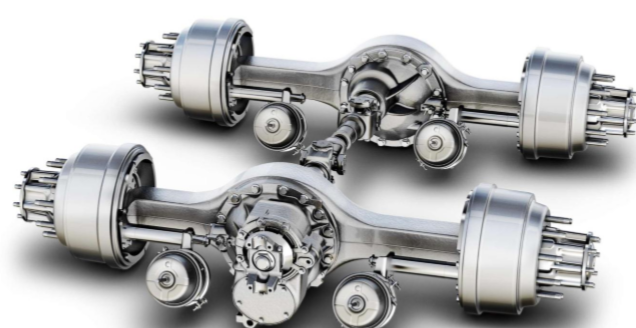

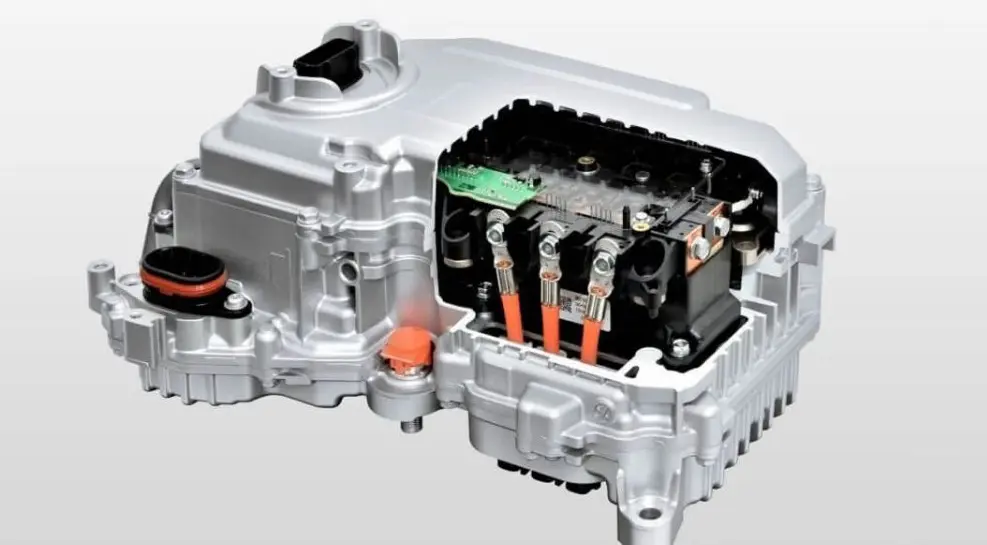

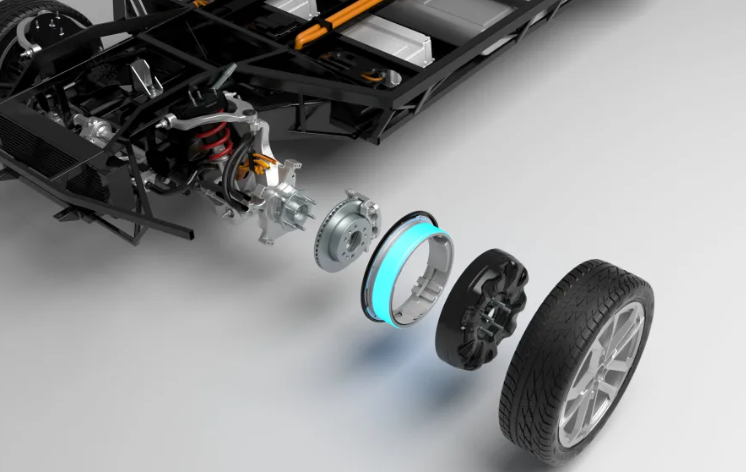

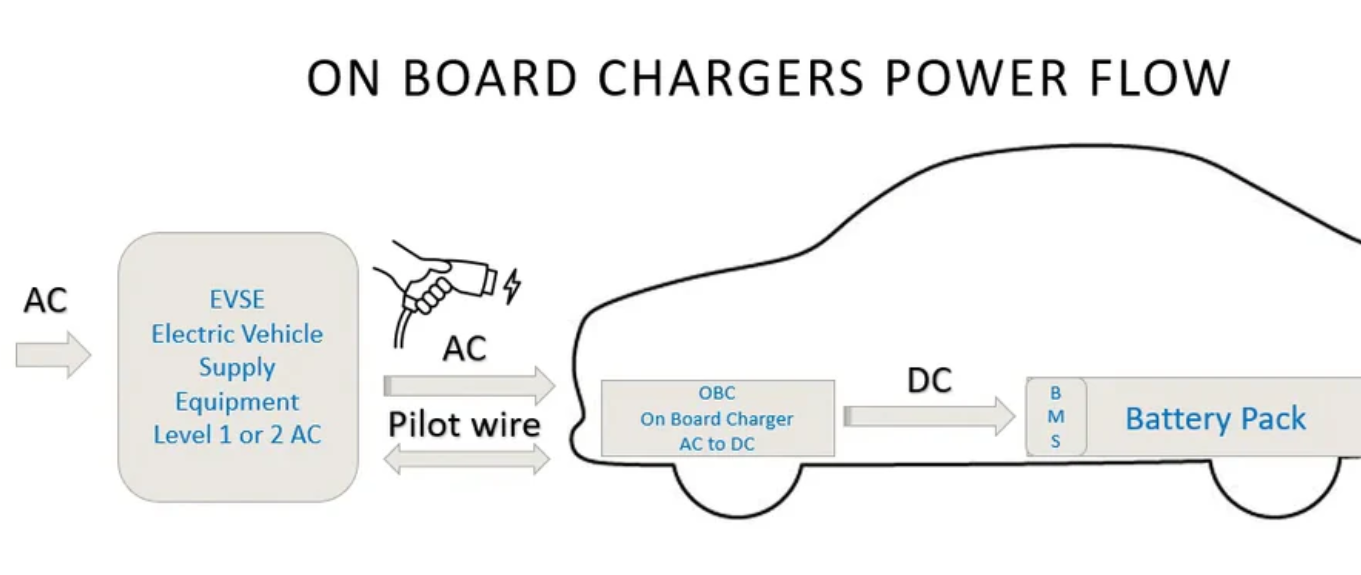

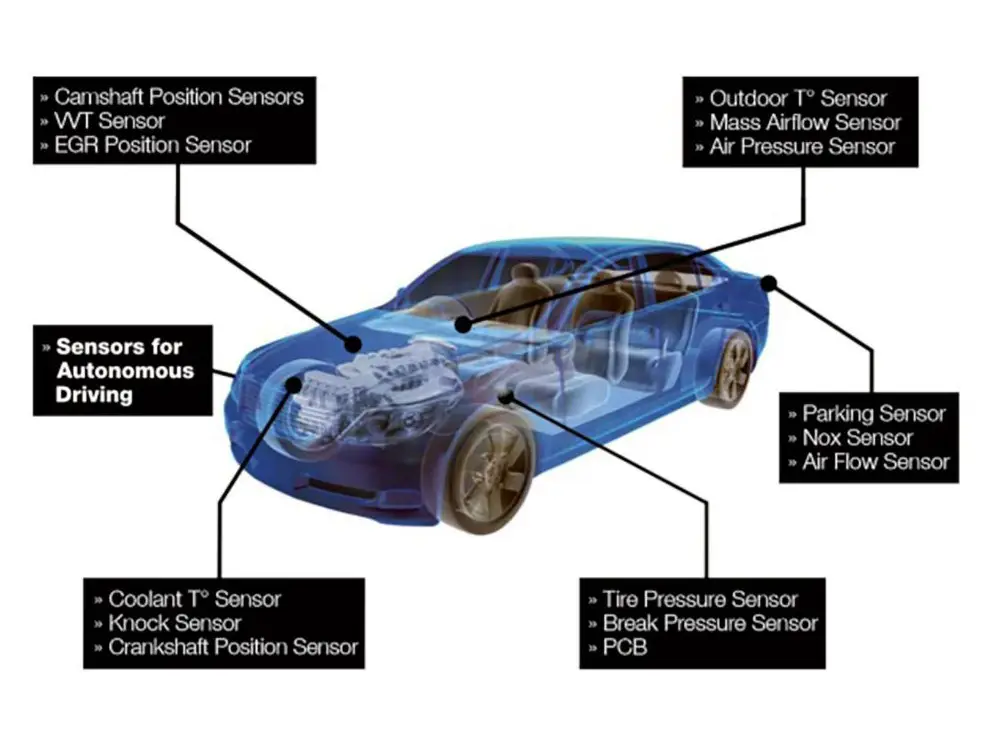

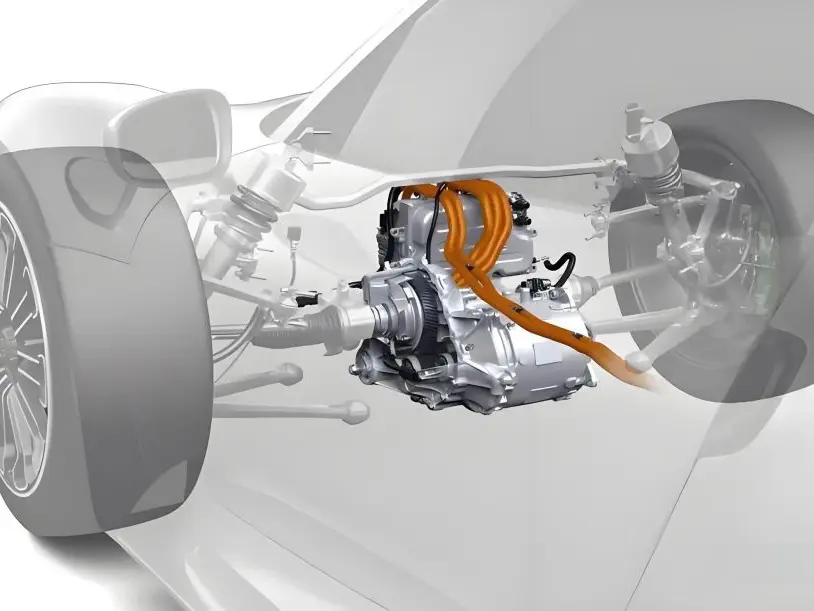

The motor + generator + compressor + cooling fan is made into an electric assembly, which completely replaces the function and position of the original engine. At the same time, the ECU of the original engine is replaced by the MCU of the electric assembly controller, and the command communication with the host VCU is maintained. So that the transformed electric excavator can completely retain the operation mode and operation performance of the original machine.

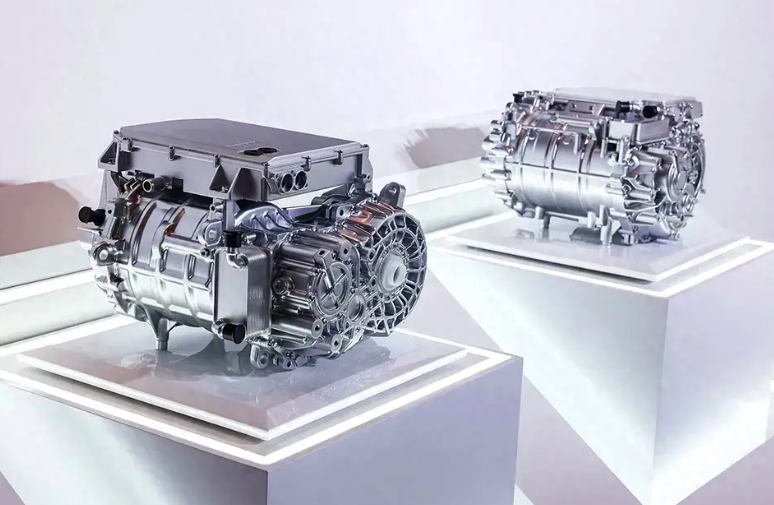

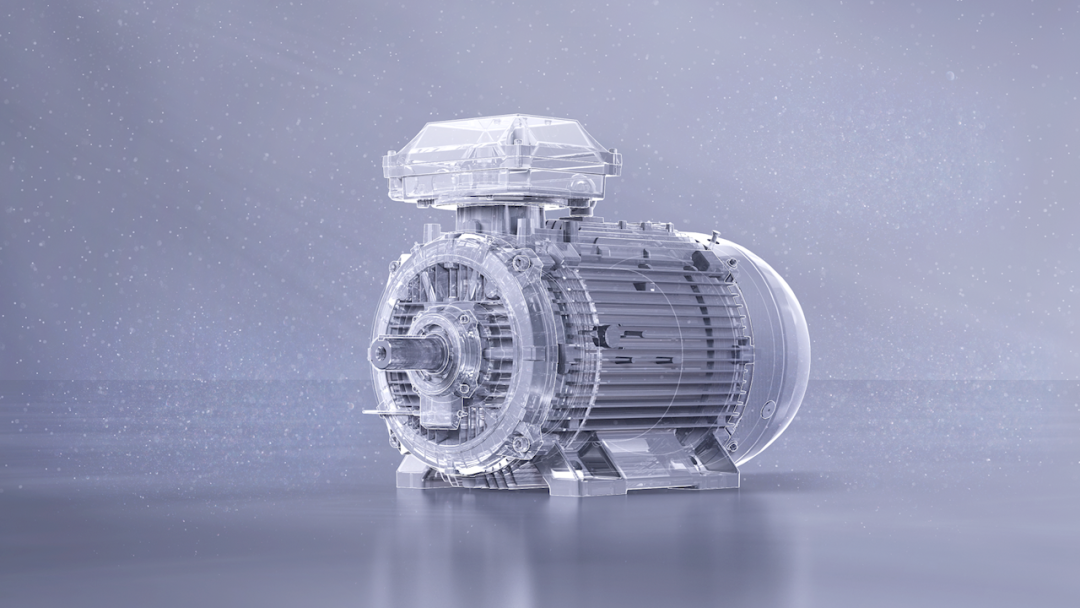

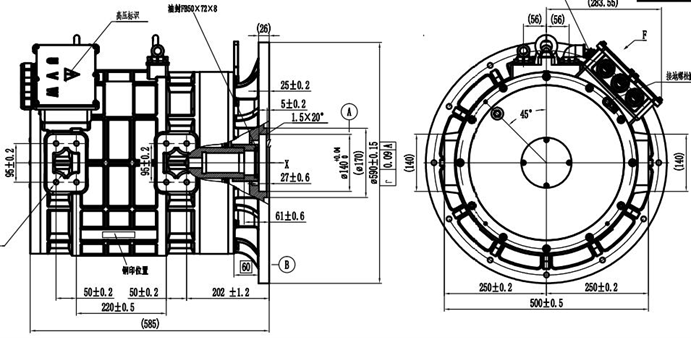

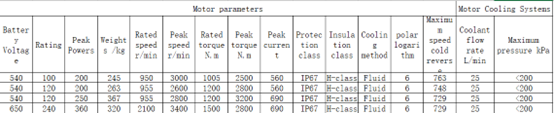

Drive motor:

Features:

1. Replace the engine assembly with an electric assembly, without changing the working capacity of the original machine, and without changing the maintenance performance of the original machine, and the overall reliability is high.

2. The electric assembly system of the excavator can be seamlessly connected with the MBB series power supply vehicle. Even in working scenarios where there is no grid power supply, you can use electricity without worry.

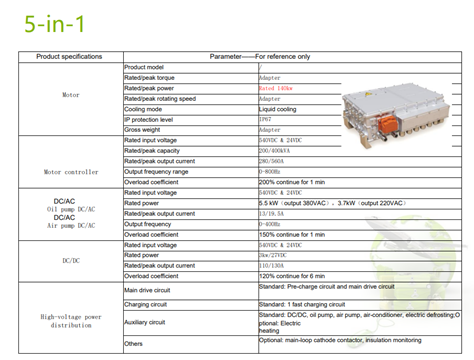

List of supplies for electrification conversions

Project Effect:

1. Energy conservation and emission reduction: Through electrification, it is expected to reduce diesel consumption by 30% and carbon emissions by 25%.

2. Improve efficiency: The electric drive system has a higher response speed and load capacity than the traditional diesel drive system, which can effectively improve the operation efficiency of the machinery.

3. Reduced maintenance costs: The maintenance cost of the electric drive system is 30% lower than that of the diesel drive system, while reducing a lot of repair time and labor costs.

4. Enhance safety: Through intelligent energy management and remote monitoring and fault diagnosis system, safety accidents caused by mechanical failures can be effectively avoided.

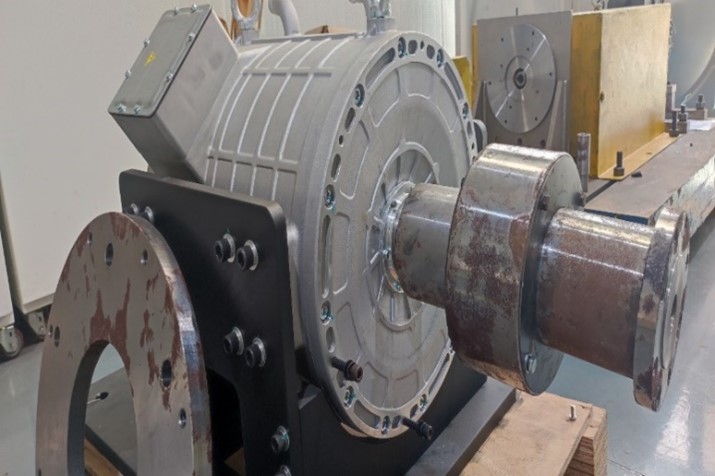

Actual production process record of the product:

Summary: "oil to electricity" excavator is a new track opened up by the company's engineering excavator on the basis of new energy power products such as hydrogen energy, methanol, pure electric, battery swap, hybrid, etc., which will effectively promote the green development process of the industry and have very important practical significance to meet the personalized needs of users. Through further research and improvement, it is expected that greater progress will be made in improving the efficiency of machinery, reducing operating costs, and enhancing safety and reliability. At the same time, it is necessary to further promote the scope of application to give full play to its potential in energy conservation and emission reduction, improve efficiency, and reduce maintenance costs.