PUMBAA Unveils Latest Electric Conversion Solutions for Oil Extraction Equipment

PUMBAA Unveils Latest Electric Conversion Solutions for Oil Extraction Equipment

Oil extraction without fuel? The real situation turns your perception upside down!

Project name: convert the diesel engine drive of oil extraction equipment to oil-electric hybrid drive

Project location: an oil field in northern China

Application scenario: electric transformation of oil exploitation equipment

Project transformation background:

A company in China's Beijing oil extraction equipment industry came to us and built their first set of gas-electric hybrid heavy drilling equipment, marking a decisive step towards zero carbon emissions.

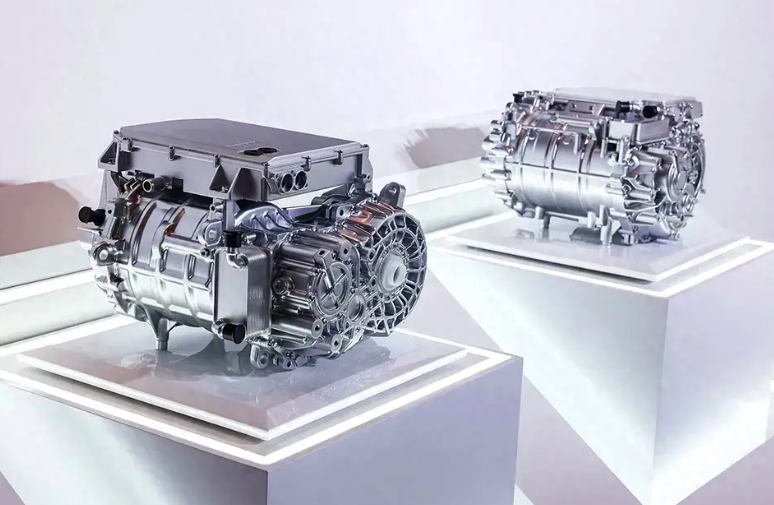

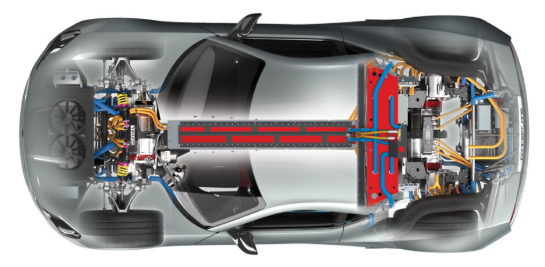

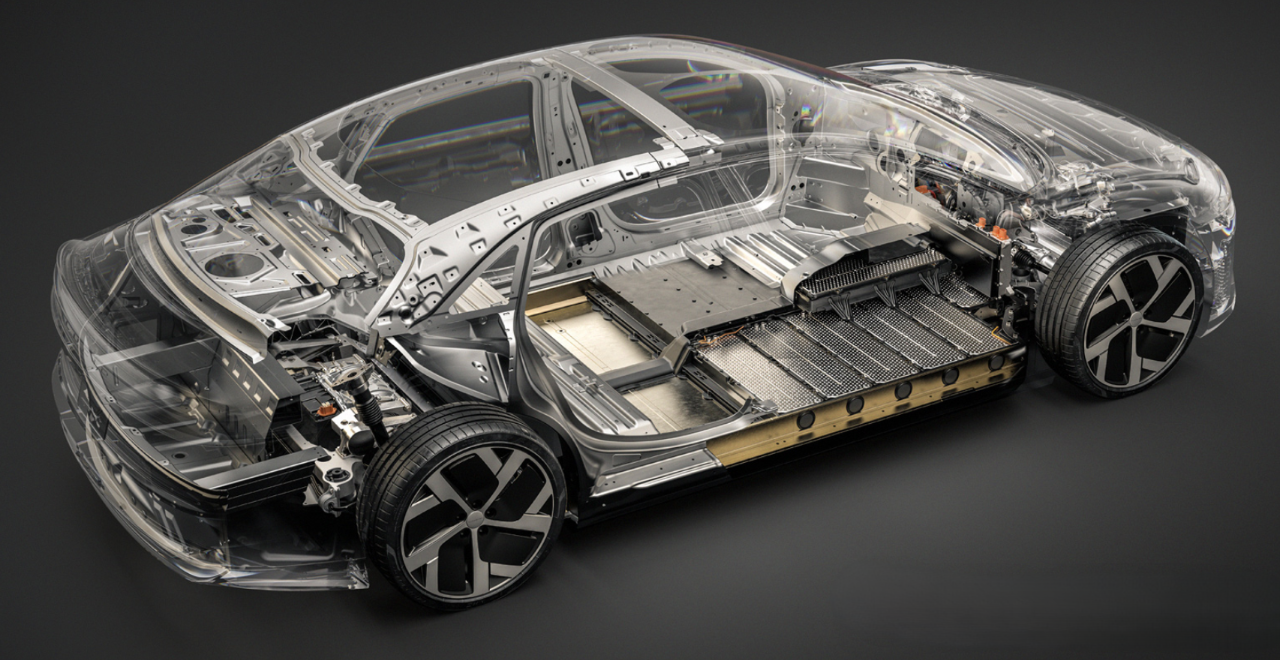

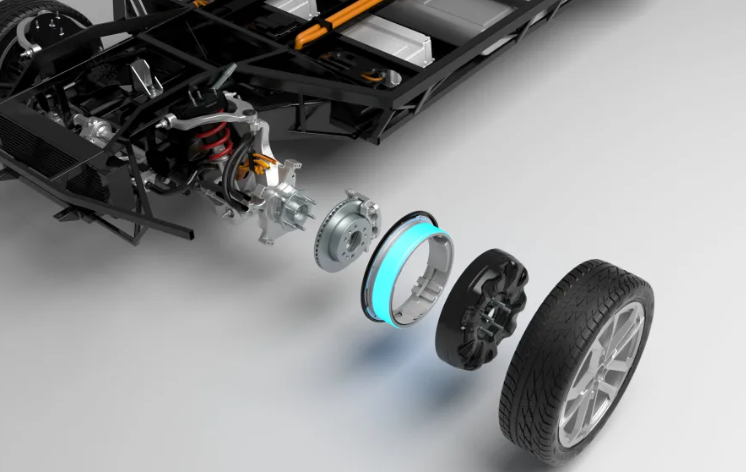

Petroleum extraction equipment Hybrid drive system equipment:

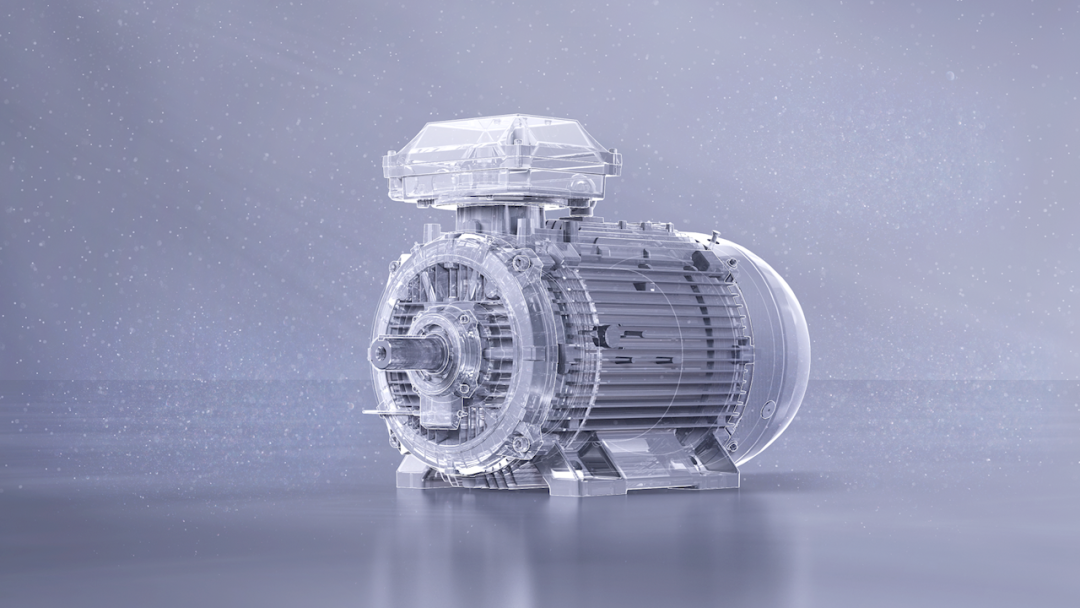

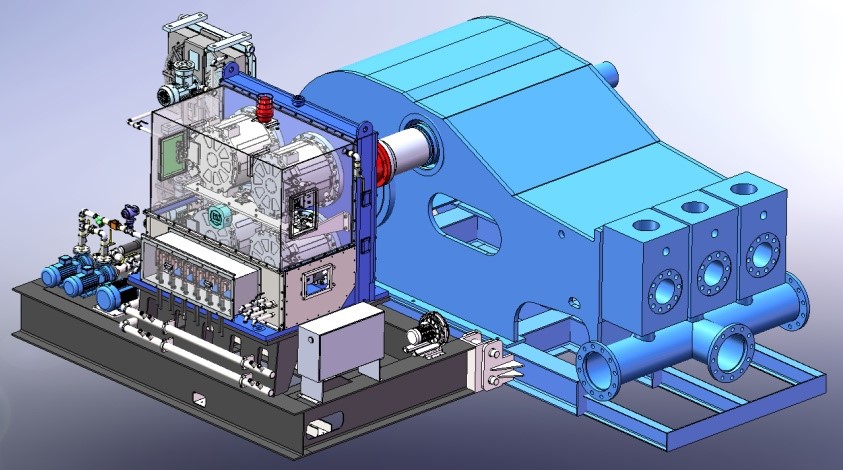

1.F-1600 mud pump pump set:

Four PUMBAAEV 300KW permanent magnet synchronous motors are configured to drive the mud pump through mechanical coupling, and the construction of the wei 349-Ping 2 well of Zhongyuan Petroleum Engineering Drilling Company 1 has been completed.

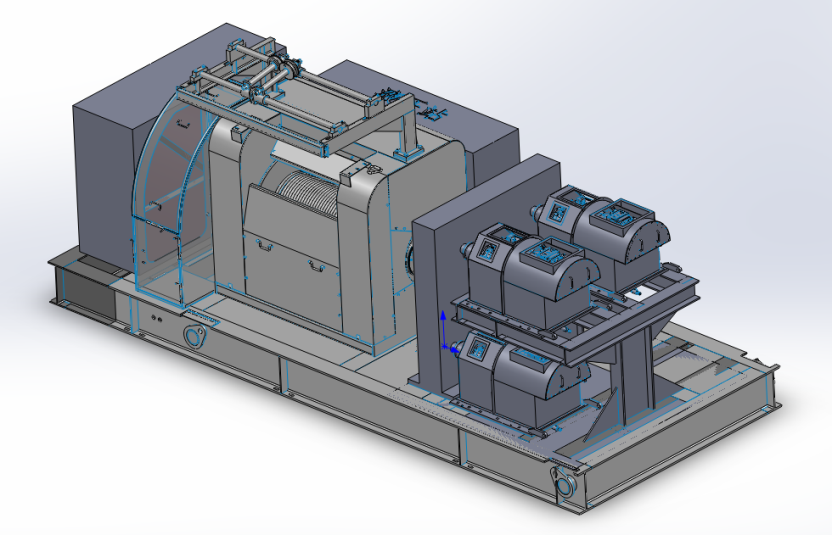

2,1000HP winch drive device:

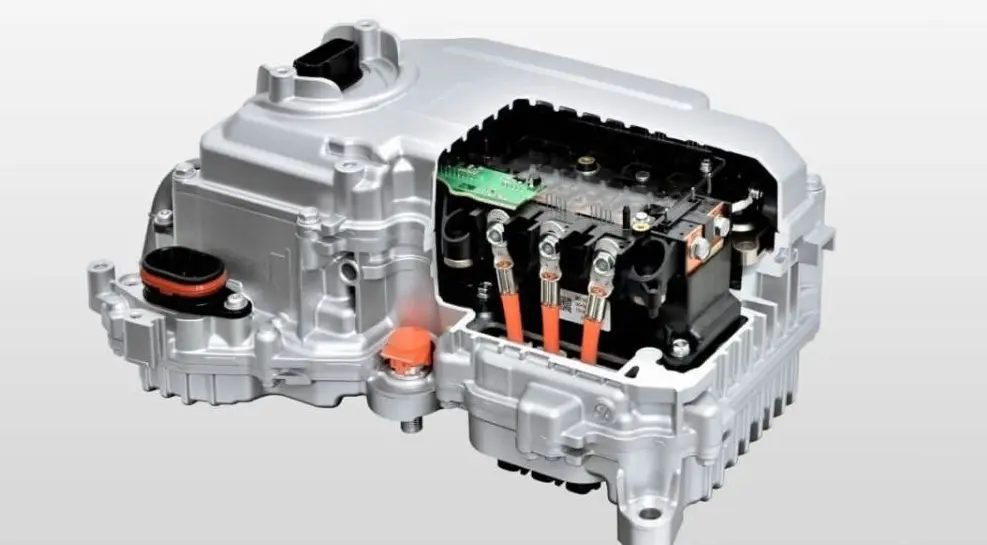

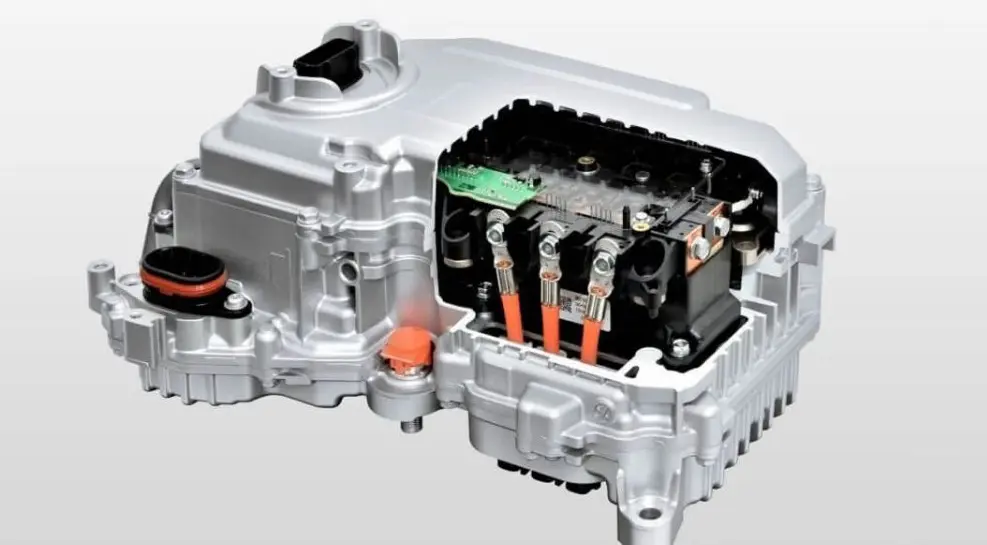

Three PUMBAAEV 300KW permanent magnet synchronous motor powertrain, using the integrated design of permanent magnet motor and four-gear transmission, driving the JC40DB winch through mechanical coupling, and is currently tested in the 40DB drilling rig of Sinopec Four Machinery Company.

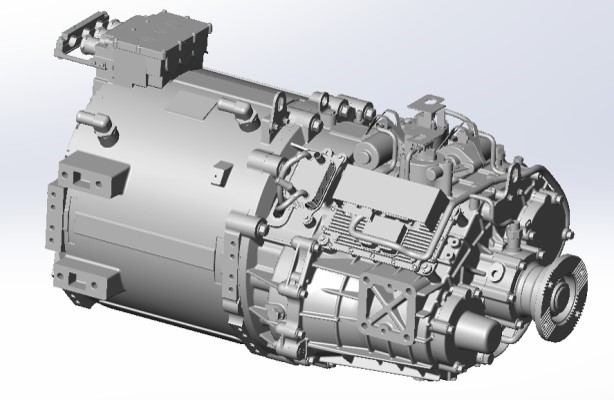

3,4x300KW permanent magnet generator set:

Four PUMBAAEV 300KW permanent magnet synchronous generator sets and rectifier device are configured, and the DC is connected to the grid. At present, the construction of wei 349-Ping 2 well of Zhongyuan Petroleum Engineering Drilling Company has been completed.

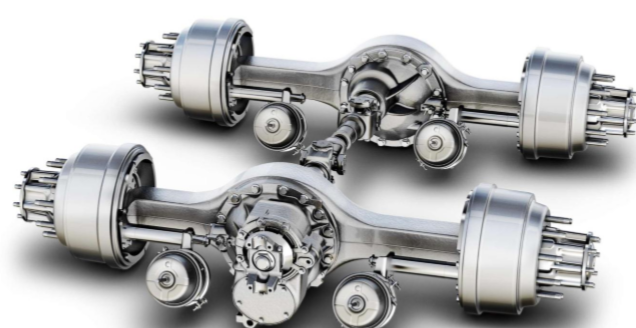

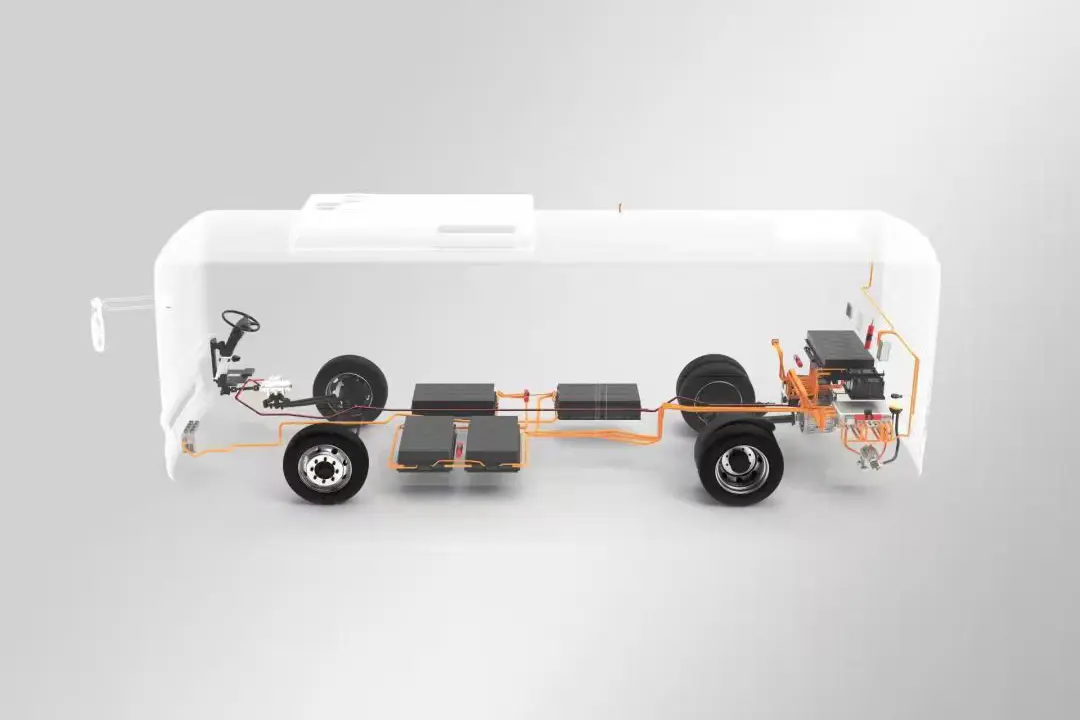

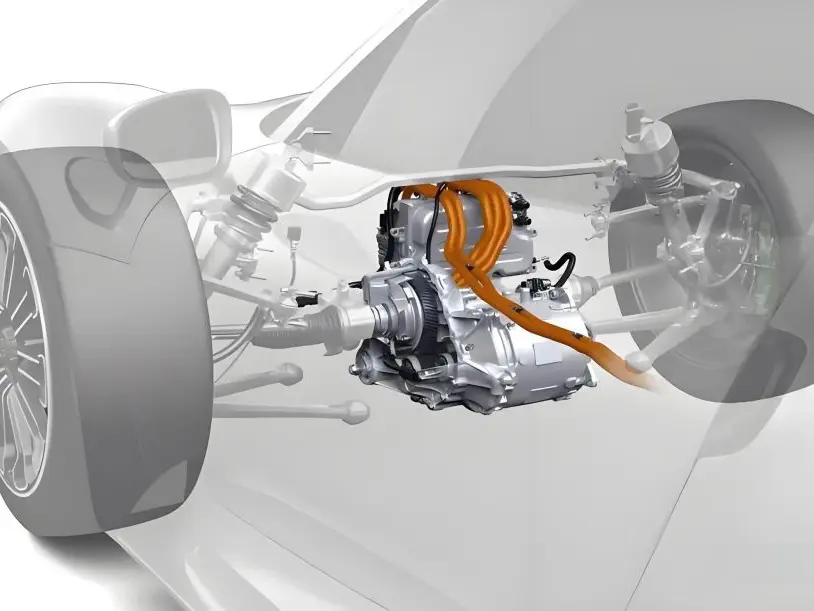

Hybrid drive system layout of oil exploitation equipment:

Advantages of hybrid power driving system for oil extraction equipment:

Lower cost: a 10% overall cost reduction;

Less energy consumption: new motors and systems save 20% of energy;

Lighter weight: less space, and 10% less weight;

Better reliability: four in one, can be standby;

PUMBAA EV Solutions provided:

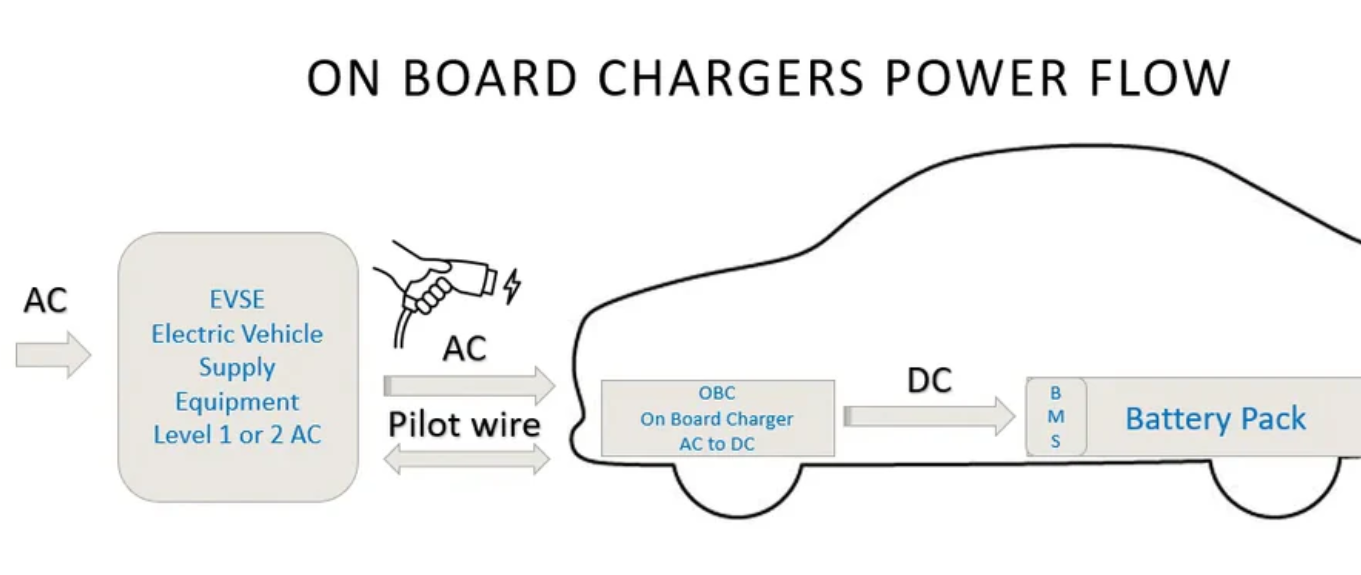

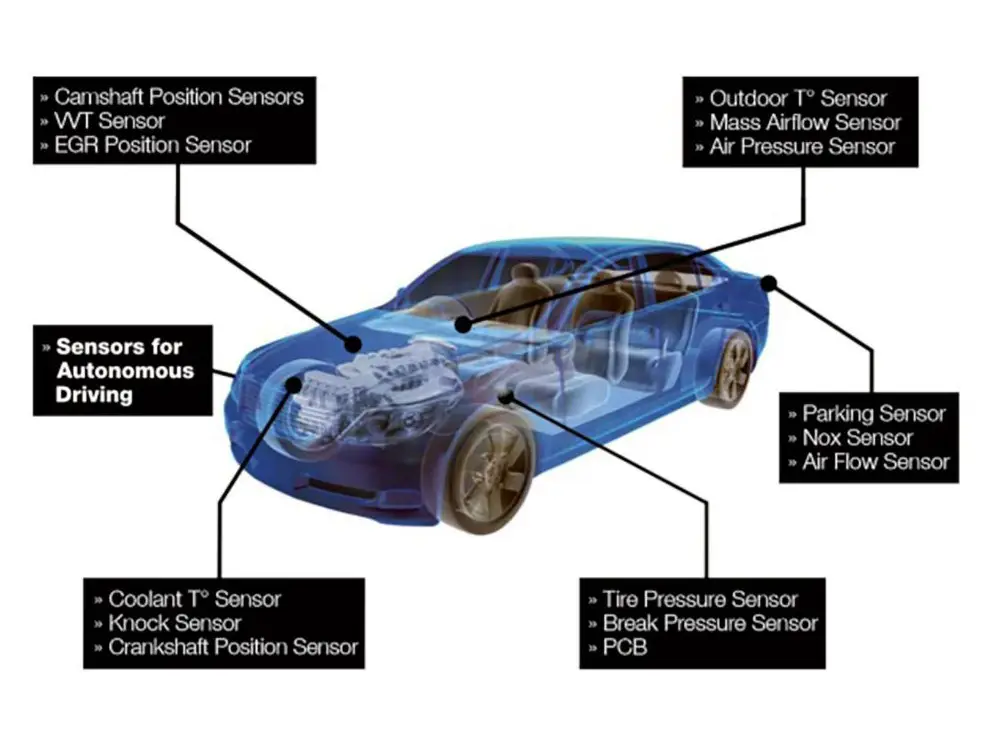

In view of the current oil rig power drive system of a series of industry pain points, revolutionary innovation, the introduction of car gauge level engine, generator, motor, control system, energy storage battery, energy management system, and combined with the condition of drilling equipment, for four years, through a series of software and hardware development, form a new type of drilling rig hybrid drive system, solve many pain points, improve the system technology advancement, reliability and economy.

Compared with the existing electric drilling rig, the unattended power system can reduce energy consumption by more than 20% and emissions by more than 30%; advanced technology, high efficiency, energy saving, green and low carbon.

After the completion of the project, we received a letter of commendation from the boss of the company, who learned of the industry's need for economical and efficient electrification of the company, and therefore provided a solution to the company in Beijing to meet their needs. Also ensures its continued performance and reliability.