High-Efficiency Motor Control Unit (MCU) for Electric Vehicles | PUMBAA

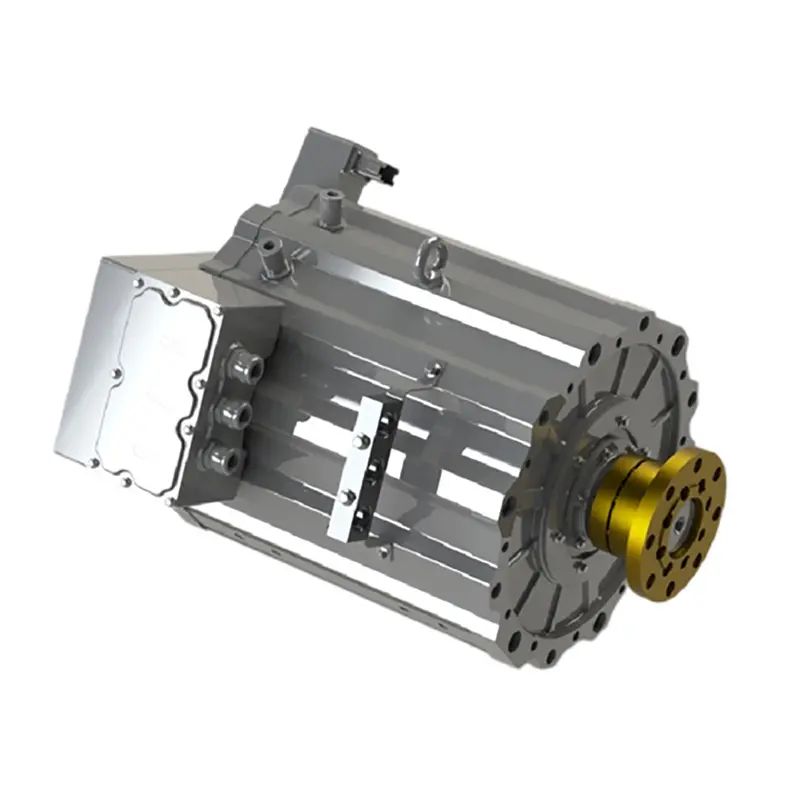

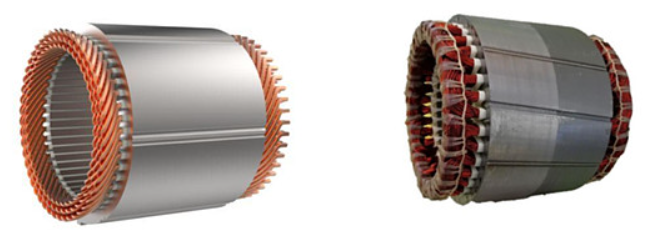

PUMBAA is a trusted leader in the field of electric vehicle drive systems, delivering advanced motor control units (MCUs) tailored for next-generation mobility. Our MCUs are designed to provide precise, efficient, and reliable control of permanent magnet synchronous motors (PMSM), enabling seamless power delivery and optimal performance in commercial EV applications.

What is a Motor Control Unit (MCU)?

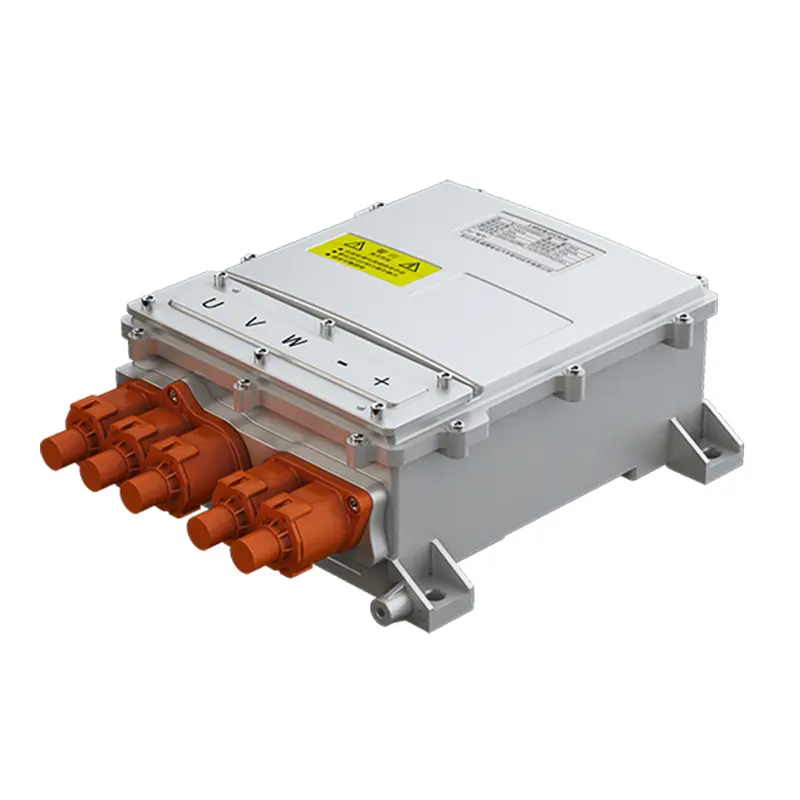

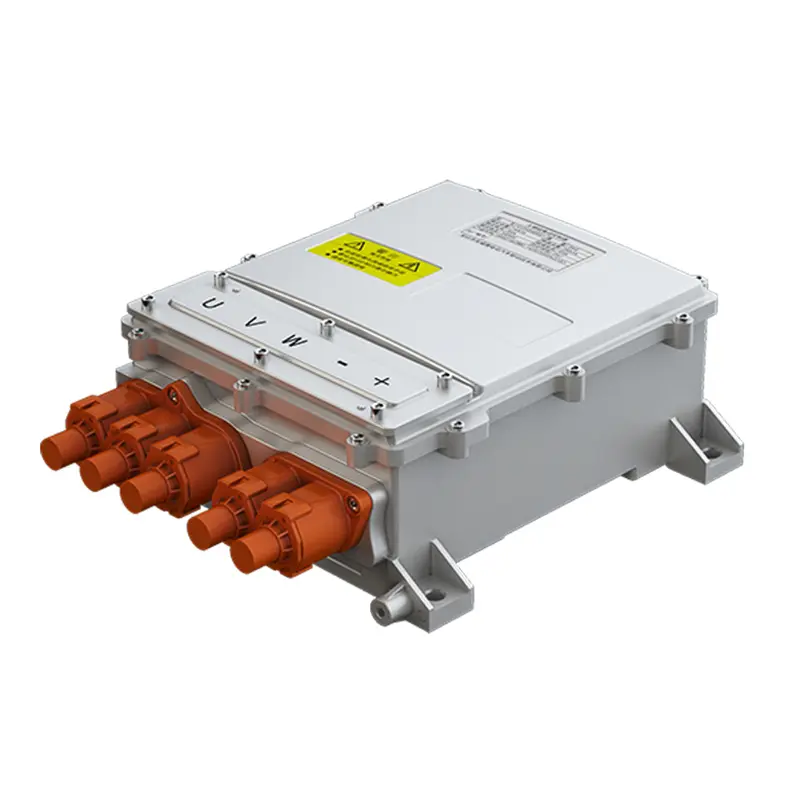

A Motor Control Unit (MCU) is the core component that governs the operation of an electric motor in electric vehicles (EVs). It receives commands from the vehicle control unit (VCU) and translates them into motor actions—controlling torque, speed, and direction. By efficiently managing voltage, current, and power flow to the motor, the MCU ensures smooth acceleration, regenerative braking, and overall driving stability.

PUMBAA EV’s motor control unit is essential for the seamless operation of electric vehicles, acting as the brain that coordinates the EV motor controller and ensures optimal performance. Our advanced technology provides precise drive motor speed control and bldc motor inverter, enabling smooth acceleration and deceleration while maximizing energy efficiency. Additionally, the integration of our reliable EV inverter ensures that power is effectively converted and distributed to the motor, delivering high performance and reliability for all types of electric vehicles.

PUMBAA’s EV Motor Controller: Designed for Performance and Efficiency

At PUMBAA, we design and manufacture EV motor controllers (MCUs) that are engineered for high-performance electric mobility. Our motor controllers support:

-

Permanent Magnet Synchronous Motors (PMSM)

-

Advanced vector control algorithms (FOC – Field Oriented Control)

-

CAN communication with VCU and battery management systems (BMS)

-

Multiple voltage platforms (high and low voltage systems)

-

Real-time fault detection and protection

These features allow for highly responsive and adaptive motor control, essential for diverse commercial EV platforms, from logistics vehicles and buses to utility and specialty vehicles.

Why Choose PUMBAA’s MCU for EV Applications?

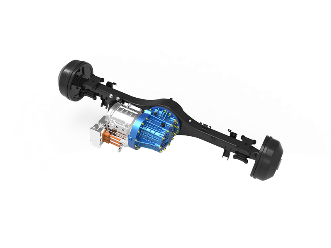

PUMBAA stands apart through innovation and system integration. Our EV motor control solutions are built to work seamlessly within a complete electric drivetrain, supporting full-stack integration with:

-

Electric Motors (PMSM)

-

Vehicle Control Units (VCU)

-

DC-DC Converters

-

On-board Chargers (OBC)

-

Power Distribution Units (PDU)

-

DC-AC Inverters

This integrated architecture minimizes compatibility issues, enhances overall system efficiency, and reduces development time for OEMs and vehicle integrators.

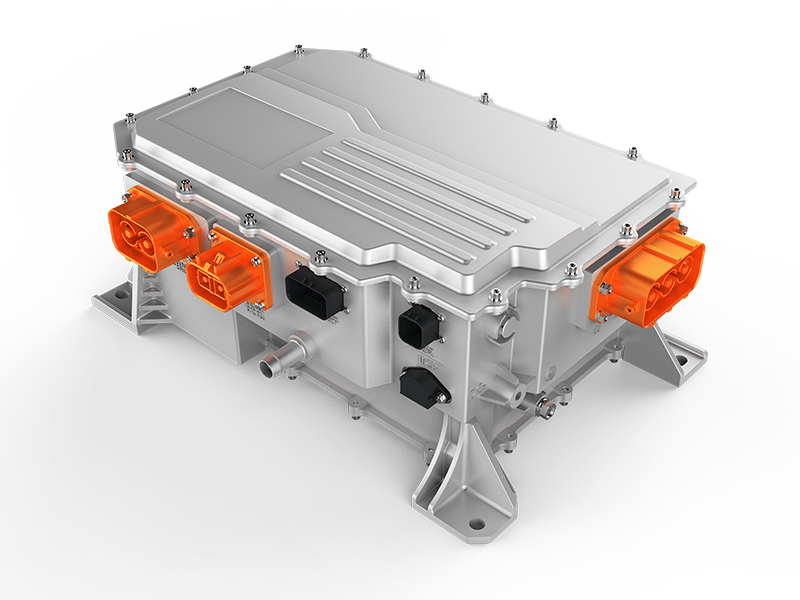

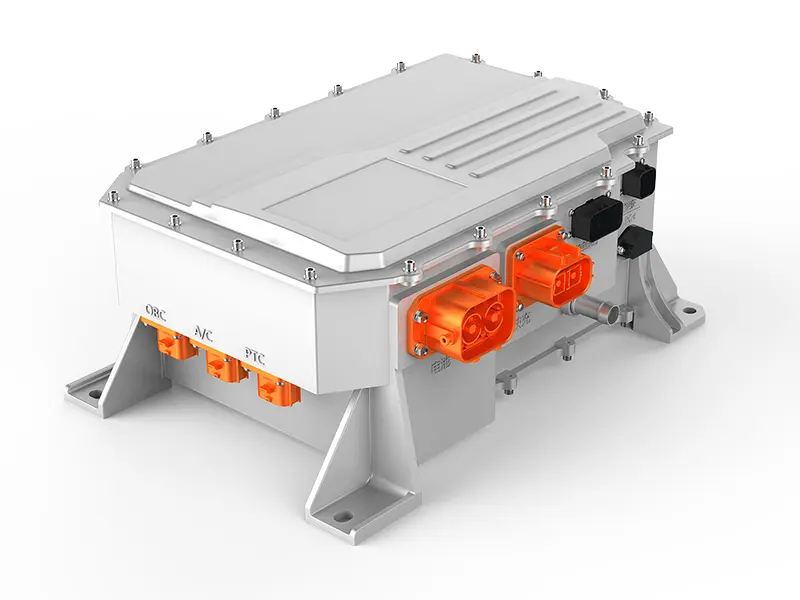

Key Features of PUMBAA’s EV Motor Controllers

-

High-Efficiency FOC Algorithm: Real-time vector control for high-speed, high-torque performance

-

Compact & Robust Design: High thermal endurance and vibration resistance for industrial-grade vehicles

-

Intelligent Communication: CAN bus, RS485, and Ethernet support for easy integration

-

Flexible Voltage Options: Compatible with 48V, 72V, 96V, 300V, and 600V systems

-

Customizable Logic and Parameters: Adaptable to your vehicle’s dynamic performance needs

-

Regenerative Braking Control: Enhances range and energy recovery

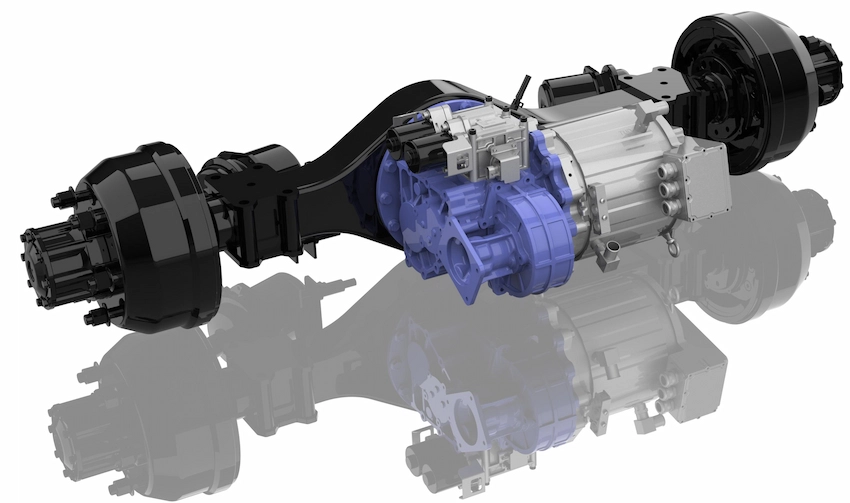

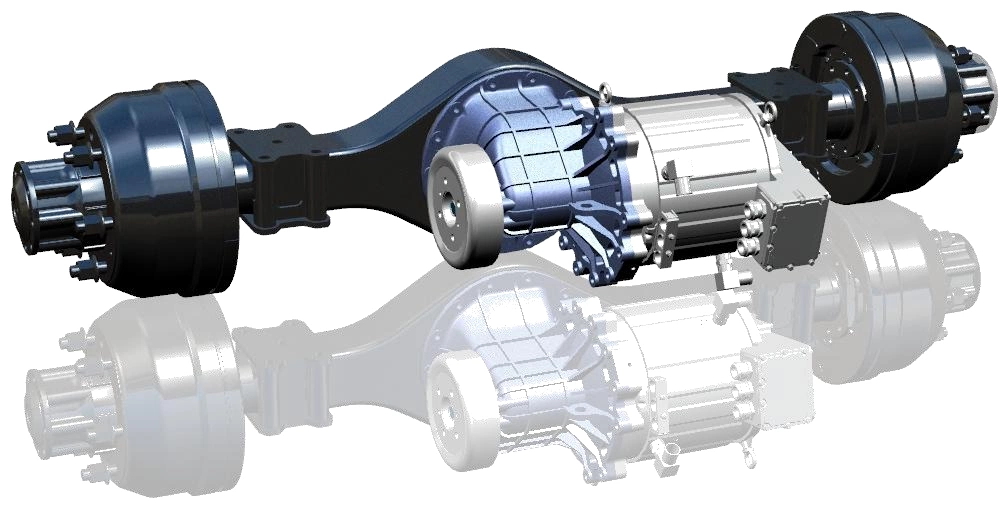

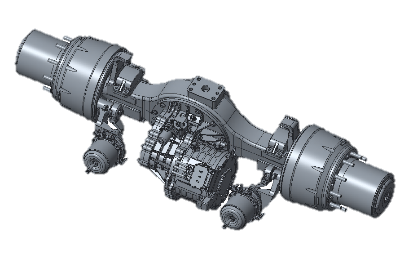

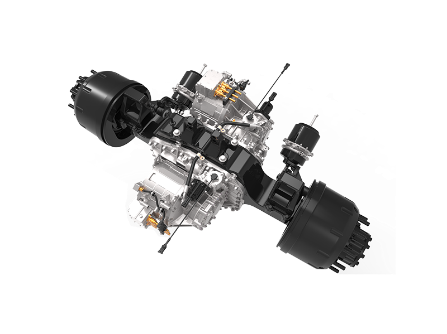

Integrated EV Drive Platform by PUMBAA

PUMBAA doesn’t just provide standalone MCUs—we offer a holistic electric vehicle drive system. From electric motors and controllers to power supply systems (DC-DC, DC-AC, OBC, PDU), we deliver a unified, scalable solution tailored for commercial EVs. Our modular design approach ensures easier adaptation, faster integration, and reduced total cost of ownership (TCO).

Partner with PUMBAA for Next-Gen EV Powertrain Solutions

As a global provider of high-efficiency EV drive systems, PUMBAA is committed to powering the future of electric mobility. Our motor control units for electric vehicles combine innovation, reliability, and performance—backed by years of engineering expertise and a deep understanding of commercial transportation needs.

Whether you're building your next-generation electric fleet or upgrading an existing one, PUMBAA’s EV MCUs will give you the performance edge you need.

High Performance for Dynamic Driving Conditions

Pumbaa’s Motor Control Units (MCUs) are engineered to deliver outstanding performance across diverse driving scenarios. With an exceptional overload capacity at low speeds and robust weak magnetic capabilities at high speeds, our MCUs ensure seamless operation in both urban environments and highway conditions. This adaptability guarantees reliable and powerful performance in any situation.

Exceptional Torque for Demanding Applications

Starting torque is critical for smooth acceleration, and Pumbaa’s MCUs excel in this area. By providing substantial current at low speeds, our controllers ensure vehicles can handle demanding conditions effortlessly, delivering the power needed to conquer steep inclines and heavy loads with ease.

Expansive Speed Capabilities for Modern Driving

As vehicles are pushed to achieve greater speeds, Pumbaa’s MCUs rise to the challenge with an expansive constant power range. Enhanced weak magnetic capabilities ensure stability and efficiency at high speeds, allowing vehicles to meet the demands of modern automotive performance without compromising reliability.

Optimized Efficiency for Extended Range

Efficiency is a key factor in the design of new energy vehicles, and Pumbaa’s MCUs are built with this in mind. By minimizing energy loss and maximizing drive system efficiency, our controllers contribute to extending the range of electric and hybrid vehicles, supporting a more sustainable and energy-conscious future.

High Performance for Dynamic Driving Conditions

Pumbaa’s Motor Control Units (MCUs) are engineered to deliver outstanding performance across diverse driving scenarios. With an exceptional overload capacity at low speeds and robust weak magnetic capabilities at high speeds, our MCUs ensure seamless operation in both urban environments and highway conditions. This adaptability guarantees reliable and powerful performance in any situation.

Exceptional Torque for Demanding Applications

Starting torque is critical for smooth acceleration, and Pumbaa’s MCUs excel in this area. By providing substantial current at low speeds, our controllers ensure vehicles can handle demanding conditions effortlessly, delivering the power needed to conquer steep inclines and heavy loads with ease.

Expansive Speed Capabilities for Modern Driving

As vehicles are pushed to achieve greater speeds, Pumbaa’s MCUs rise to the challenge with an expansive constant power range. Enhanced weak magnetic capabilities ensure stability and efficiency at high speeds, allowing vehicles to meet the demands of modern automotive performance without compromising reliability.

Optimized Efficiency for Extended Range

Efficiency is a key factor in the design of new energy vehicles, and Pumbaa’s MCUs are built with this in mind. By minimizing energy loss and maximizing drive system efficiency, our controllers contribute to extending the range of electric and hybrid vehicles, supporting a more sustainable and energy-conscious future.

Leave Your Message

FAQs for EV Motor Controllers

Advanced MCUs utilize field-oriented control (FOC) and adaptive pulse-width modulation (PWM) strategies to optimize switching. These methods reduce switching losses and improve motor efficiency, especially in high-speed operations where weak magnetic control is crucial.

Thermal management is critical for maintaining the reliability of motor controllers. Modern MCUs incorporate real-time temperature monitoring and predictive thermal algorithms to ensure stable operation under high-load conditions, improving the system’s longevity and performance.

Motor control units intelligently modulate braking torque by controlling the inverter and managing energy recovery. This precise control maximizes the efficiency of regenerative braking systems while ensuring smooth transitions between braking modes.

SiC-based power electronics are enabling higher efficiency, faster switching, and reduced heat generation in motor controllers. These advancements allow for more compact designs, improved thermal performance, and better high-speed control for EV motors.

In multi-motor setups, MCUs coordinate torque distribution and speed synchronization across multiple motors using advanced communication protocols and centralized algorithms. This ensures optimal performance, improved traction control, and enhanced vehicle stability in complex driving conditions.