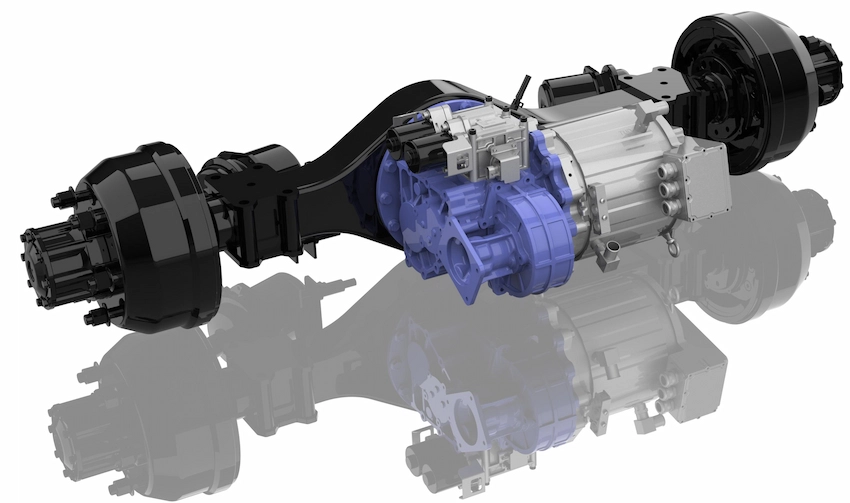

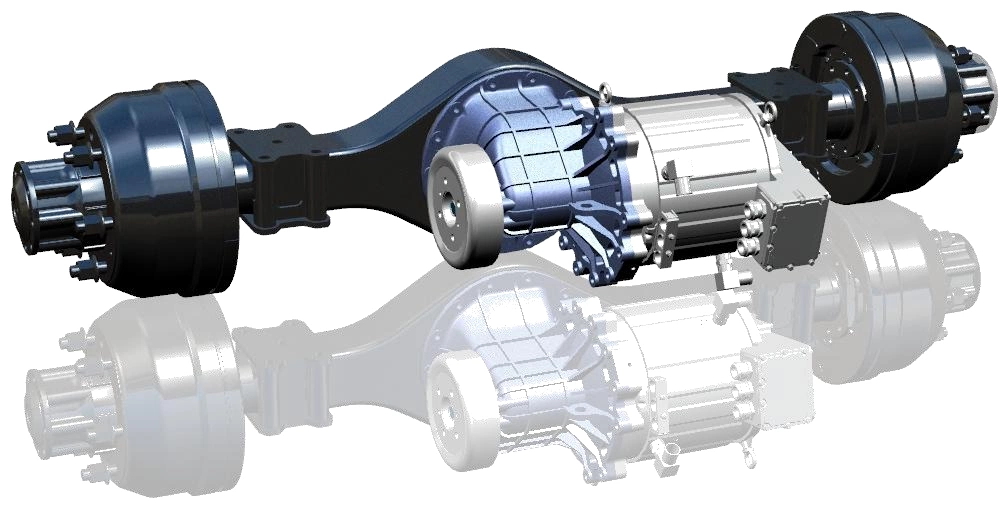

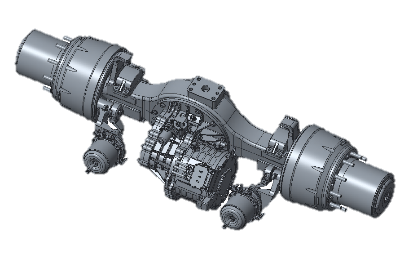

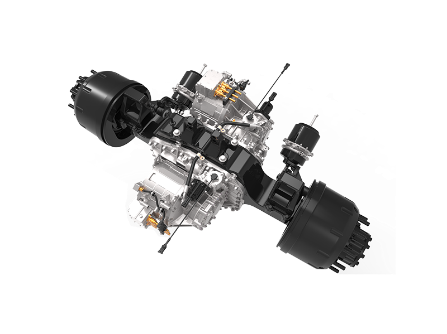

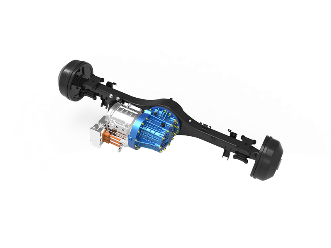

Electric Vehicles Drive System Solutions

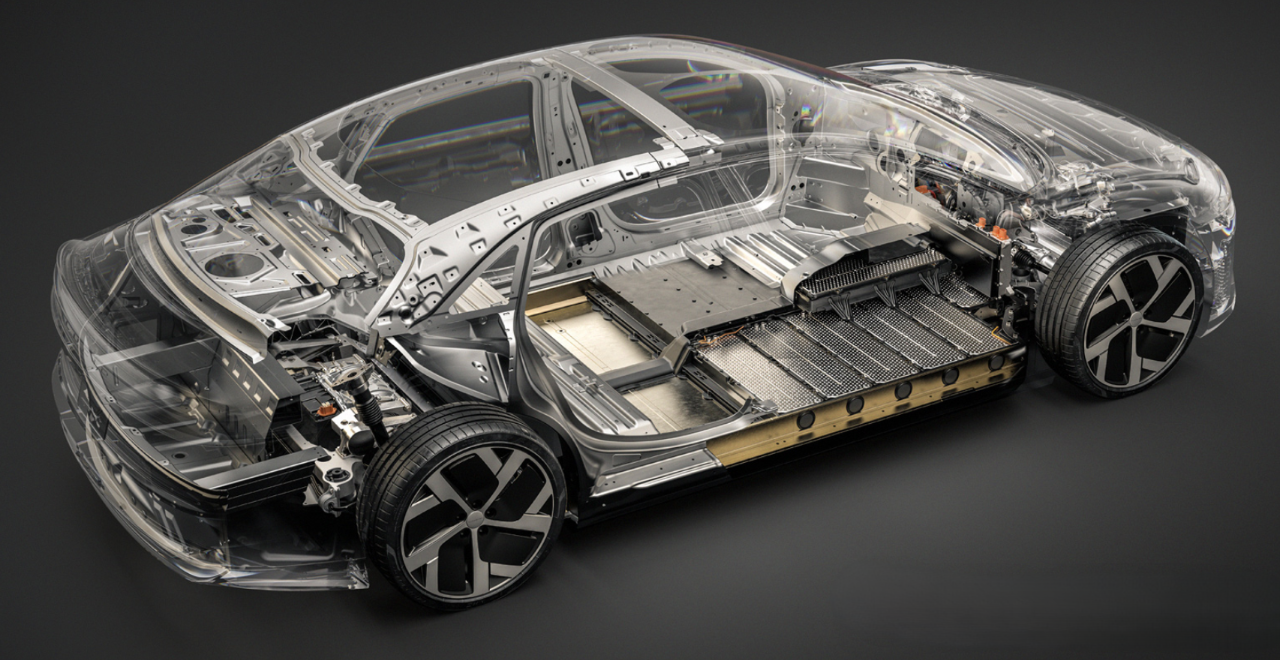

At the heart of PUMBAA’s innovation is our Electric Vehicles Drive System, a fully integrated solution engineered for maximum efficiency, durability, and adaptability. Whether for logistics vans, buses, light trucks, or special-purpose electric vehicles, our drive systems are optimized to deliver high torque density, superior thermal performance, and long lifecycle reliability. From the motor to the power electronics, each component is designed to work in seamless harmony, enabling smoother acceleration, improved energy utilization, and reduced maintenance costs.

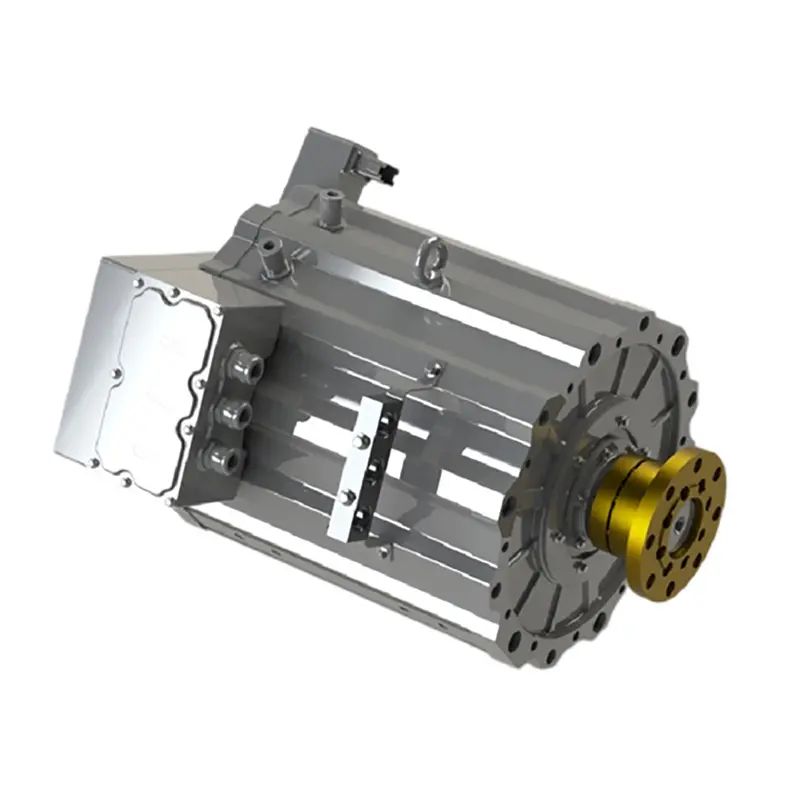

Permanent Magnet Synchronous Motors (PMSM)

PUMBAA’s Permanent Magnet Synchronous Motors (PMSM) are precision-engineered to offer industry-leading power density and energy efficiency. Our motors are compact, lightweight, and built for performance across a wide range of voltage and torque requirements. By using high-grade rare earth magnets and advanced thermal management techniques, PUMBAA’s PMSM solutions ensure high continuous power output with minimal energy loss. These motors are ideal for commercial EVs requiring stable and efficient propulsion under heavy duty cycles.

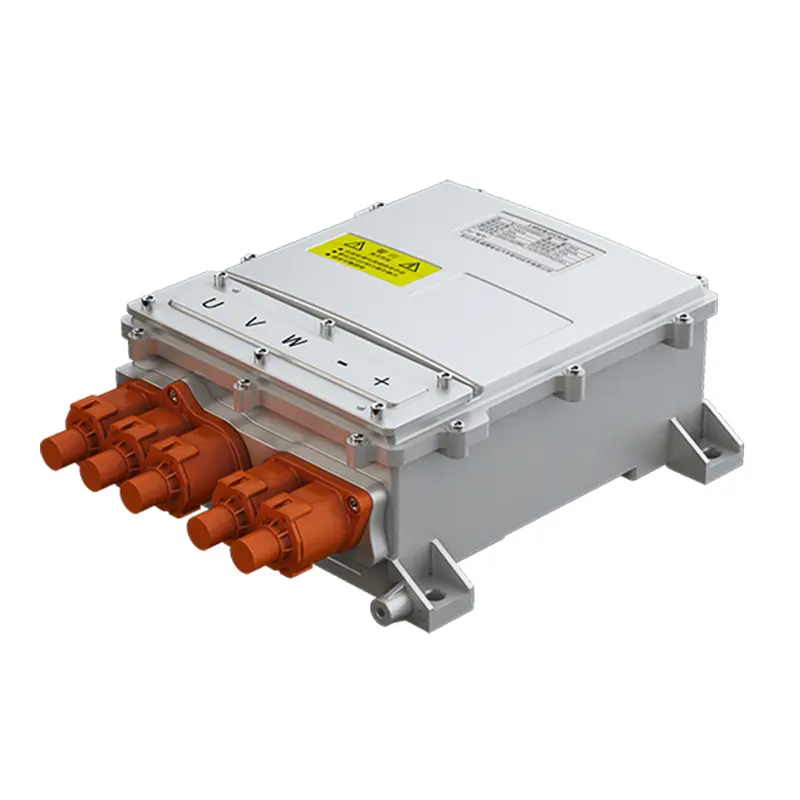

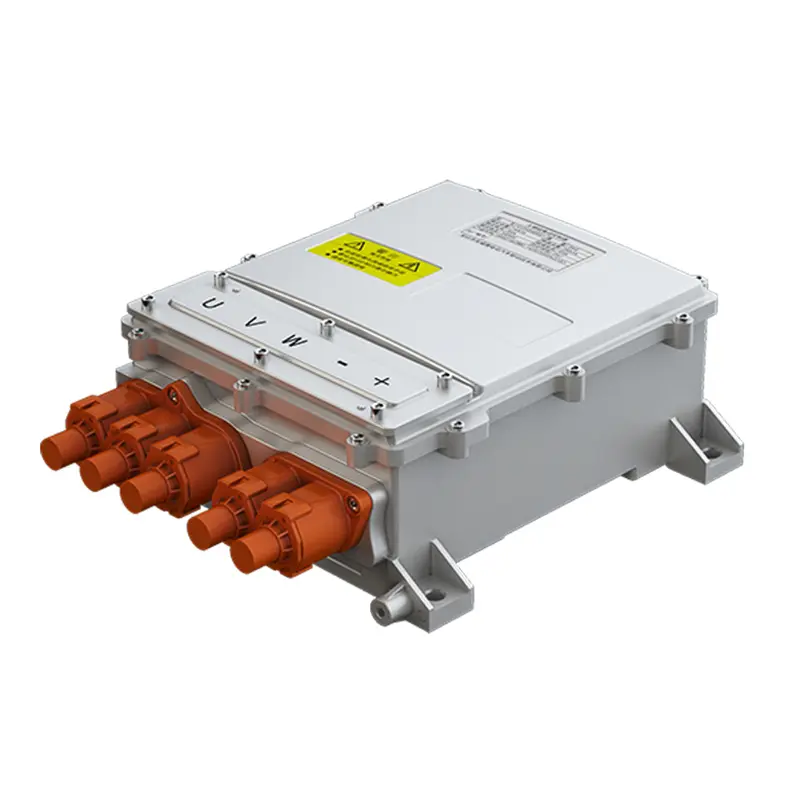

Electric Vehicle Motor Controllers (MCU)

The Motor Control Units (MCUs) developed by PUMBAA are built to provide intelligent, real-time control of electric drive systems. Supporting both vector control and field-oriented control (FOC), our MCUs deliver fast dynamic response and precise torque regulation. Designed to integrate smoothly with PMSM motors, the MCU acts as the digital brain that ensures high-efficiency operation under varying load conditions. Whether for regenerative braking, drive optimization, or safety monitoring, our MCUs offer a robust control platform for commercial EV deployment.

Controllers for Electric Vehicles (VCU)

PUMBAA’s Vehicle Control Units (VCU) serve as the centralized command system for electric vehicles, coordinating communication between the motor controller, battery management system (BMS), power conversion units, and the vehicle’s onboard diagnostic system. Our VCU software stack is built on a modular architecture, allowing OEMs to configure or customize according to vehicle class, application type, or regional standards. With advanced CAN communication protocols and ISO 26262-compliant safety features, our VCUs deliver reliable vehicle-level intelligence and orchestration.

Electric Vehicle Power Supply Systems (DCDC, DCAC, OBC, PDU)

Beyond the core drive components, PUMBAA offers a comprehensive suite of electric vehicle power supply systems, including DC-DC converters, DC-AC inverters (EV inverter), On-board Chargers (OBC), and Power Distribution Units (PDU). These systems ensure efficient energy conversion and stable power delivery across the EV’s electrical architecture. Our DCDC units provide isolated voltage conversion for low-voltage subsystems, while the DCAC inverters supply clean AC power for auxiliary applications. Each power module is optimized for thermal performance, EMI suppression, and system integration — forming the electrical backbone of reliable and scalable EV platforms.

Customization and Application Flexibility

What sets PUMBAA apart is not only our technology, but our flexibility in adapting to diverse application scenarios. We provide both standard, off-the-shelf components and fully customized solutions that address unique client specifications, from voltage ratings and mounting interfaces to software parameterization and thermal configurations. This adaptability makes PUMBAA a preferred partner for OEMs and EV integrators looking to accelerate their development cycle without compromising on system performance or safety.

Is it worth converting a car to electric?

Deciding whether converting a car to electric is worth it depends on several factors, including financial costs, environmental goals, vehicle condition, and your driving needs. Here's a detailed breakdown:

1. Financial Considerations

While the initial cost of conversion is high, the long-term savings on fuel and maintenance can offset the investment. For those focused on long-term economic benefits, converting to electric can be a practical way to reduce daily operating expenses.

2. Environmental Benefits

An electric conversion significantly reduces carbon emissions and reliance on fossil fuels. If paired with renewable energy for charging, the environmental impact is even greater. Additionally, extending the lifespan of an existing vehicle helps avoid the environmental costs of manufacturing a new one.

3. Customization and Performance Improvements

Conversions offer the opportunity to tailor the vehicle to your specific needs, from enhancing acceleration to optimizing range. This is particularly appealing for owners of classic or unique cars, allowing them to preserve their vehicle’s character while upgrading its technology.

FAQs for EV Motors, Controllers, and Conversion Kits

The price of an electric car motor depends on several factors, including power output (kW), efficiency, cooling type (air-cooled vs. liquid-cooled), brand reputation, and the type of motor (AC induction, permanent magnet synchronous, or BLDC). Customization requirements, such as specific torque or speed characteristics, also affect pricing.

EV motors and controllers form the core of an electric vehicle’s powertrain. The controller manages the flow of electrical energy from the battery to the motor, regulating speed, torque, and efficiency. It translates the driver’s input (via the accelerator pedal) into precise control signals, ensuring smooth acceleration and regenerative braking.

A DC-DC converter module steps down the high-voltage DC from the main EV battery to a lower voltage, typically 12V, to power auxiliary systems like lighting, infotainment, and climate control. It ensures stable and efficient power delivery to these systems without overloading the main battery pack.

A universal electric car conversion kit typically includes:

- Electric motor (AC or DC)

- Motor controller

- Battery pack and management system (BMS)

- DC-DC converter module

- Wiring harness and connectors

- Throttle control and adapter plates

- Mounting hardware

These kits are designed to be adaptable to a wide range of vehicles, but some customization may still be required for specific models.

An EV powertrain is much simpler, consisting primarily of an electric motor, controller, battery pack, and transmission (often single-speed). It lacks the complex components of an ICE powertrain, such as a fuel tank, exhaust system, multi-gear transmission, and engine cooling systems. This simplicity results in lower maintenance, higher efficiency, and faster power delivery.

Key factors to consider include:

- Motor power and torque: Ensure it meets the performance needs of your vehicle.

- Voltage compatibility: The controller and motor must operate on the same voltage.

- Cooling requirements: Air-cooled systems are simpler, but liquid-cooled systems handle higher loads better.

- Regenerative braking capability: Allows energy recovery during deceleration.

- Vehicle weight and usage: Heavier vehicles or those used for towing may require more robust motors and controllers.

Contact Pumbaaev Drive Tech