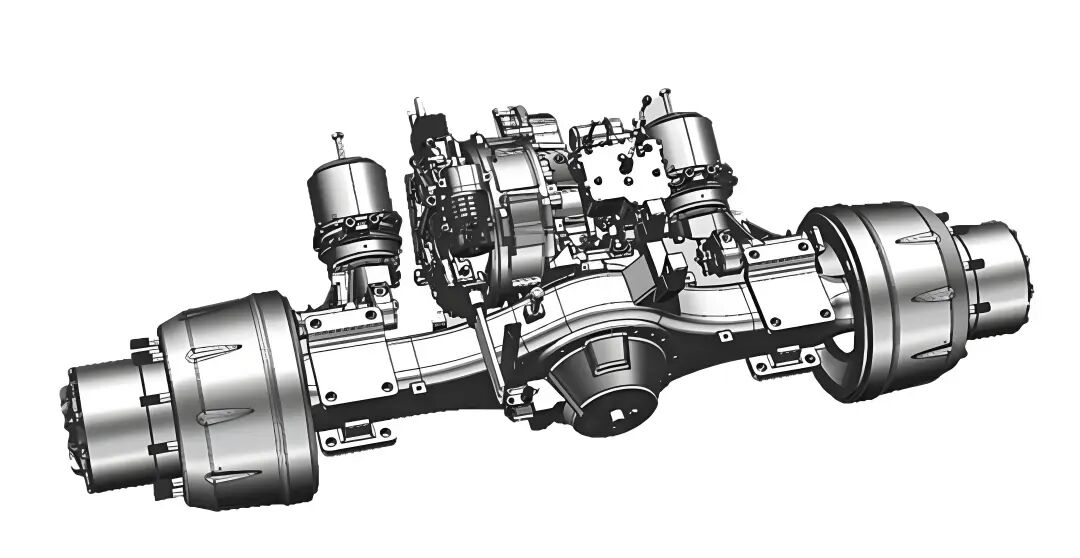

4.5T rear e-axle for light truck

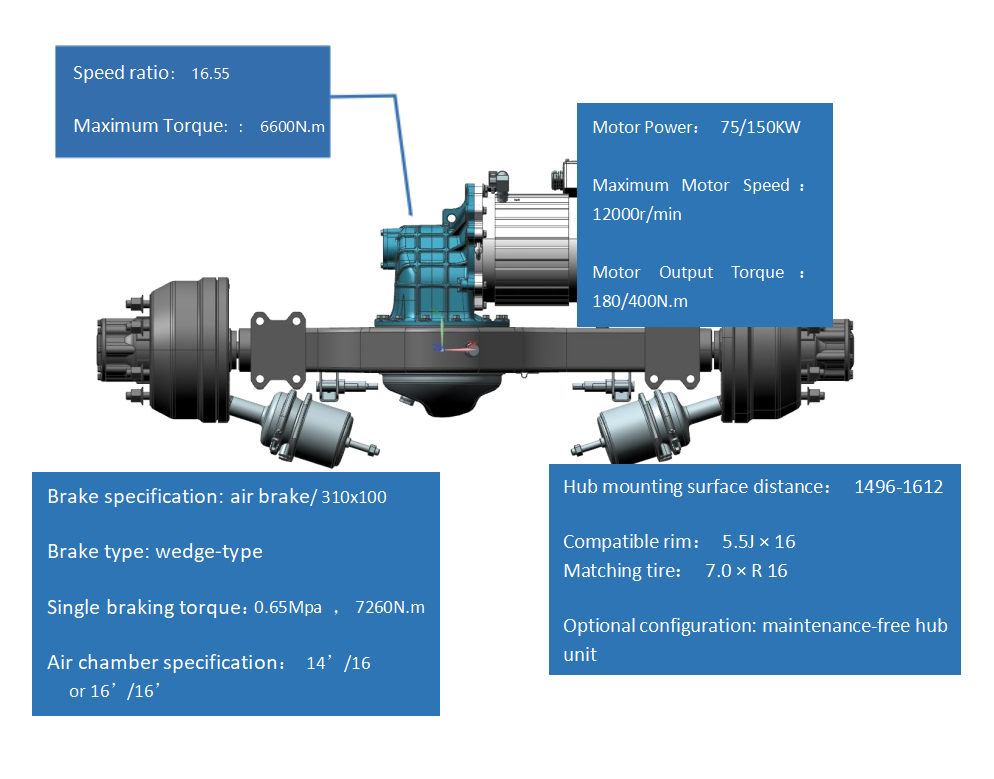

Pumbaa 4.5T e-drive rear axle parameters

Model:PMQX2100100A-4.5/160

description2

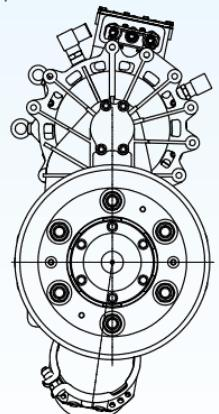

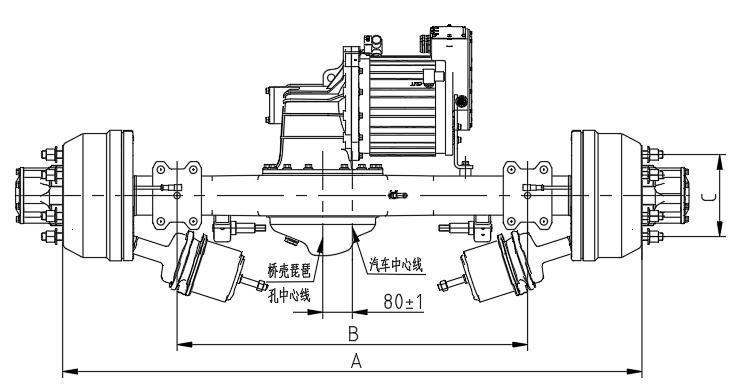

Pumbaa 4.5T rear E-axle structure and function diagram

description2

Pumbaa 4.5T rear e-axle Configuration Parameters

|

Rated Load(kg) |

4500 |

Speed ratio |

16.55 |

|

Maximum Load(kg) |

7500 |

Maximum Torque (N.m) |

6600 |

|

Maximum Speed(Km/h) |

≥100 |

Maximum Gradeability |

25% |

|

Sustainable Speed(Km/h) |

80 |

Axle housing structural form |

Stamping and welding |

|

Rim mounting surface distanceA(mm) |

1570±2 |

Axle housing cross section(mm) |

106×106×6 |

|

Spring Distance B ( m m ) |

950±1 |

Brake specification |

Air brake 310×100 (wedge type) |

|

Wheel bolt distribution circle C(mm) |

ø222.25 |

Brake air chamber specification |

16'/16′ |

|

Wheel bolt |

6-M20×1.5 |

Single braking torque |

0.65Mpa,7260N.m |

|

Rim flange diameter |

ø163.8 |

Hub mounting surface distance |

1496-1612 |

|

Compatible tire |

7.0×R16 |

Compatible rim |

5.5J×16 |

|

Wheel alignment method |

Flange positioning |

|

|

|

Optional configuration |

Maintenance-free hub unit; Air brake drum-type "S" cam brake; Disc brake |

||

|

|

|||

|

Motor type |

PMSM |

Protection Rating |

IP67 |

|

Motor peak power(Kw) |

150 |

Motor rated voltage(VDC)(V) |

540 |

|

Motor rated power(Kw) |

75 |

Voltage operating range(VDC)(V) |

350~750 |

|

Motor peak torque(N.m) |

400 |

Motor maximum speed(rpm) |

12000 |

|

Motor rated torque(N.m) |

180 |

Motor rated speed(rpm) |

3979 |

|

Insulation Class |

H |

Duty |

S9 |

description2

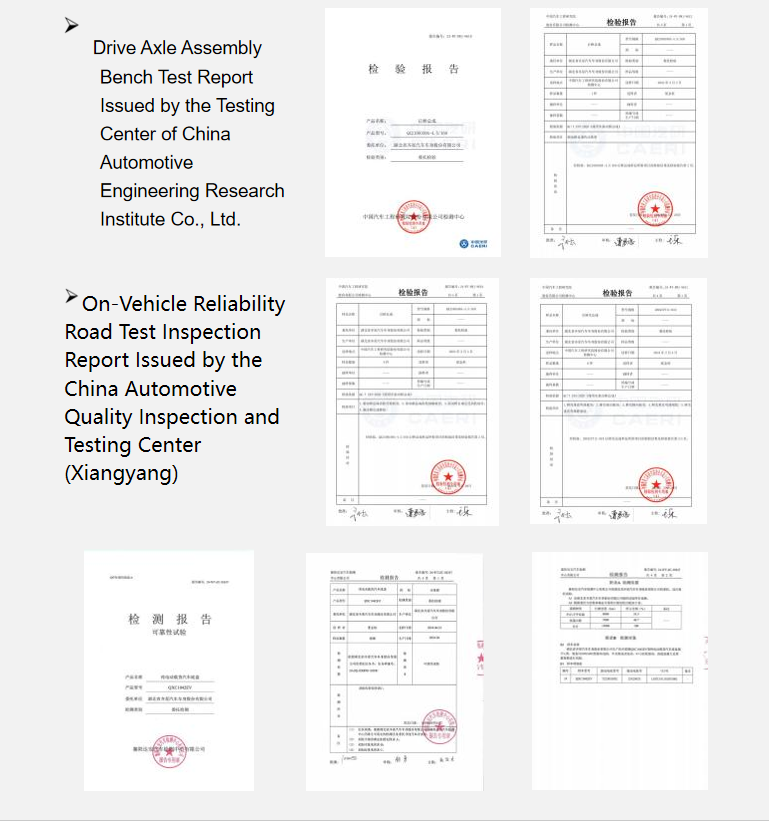

Pumbaa 4.5T rear E-axle inspection and test

description2

Vehicle Parameters By Pumbaa 4.5T rear E-axle

|

Curb weight(kg) |

3680 |

|

Full Load/Overloaded Gross Mass(kg) |

4500/7500 |

|

Tire model |

7.50R16LT |

|

Maximum Gradeability |

25% |

|

Vehicle Maximum Parking Gradeability |

20% |

|

Maximum Speed(km/h) |

100 |

|

Economic Speed(km/h) |

60~80 |

|

0~50km/h Acceleration Time(S) |

≤15 |

|

30~0km/h Braking Distance(m) |

≤10(Unladen)、≤12(Full Load) |

description2

Application for Pumbaa 4.5T rear E-axle: light trucks

description2

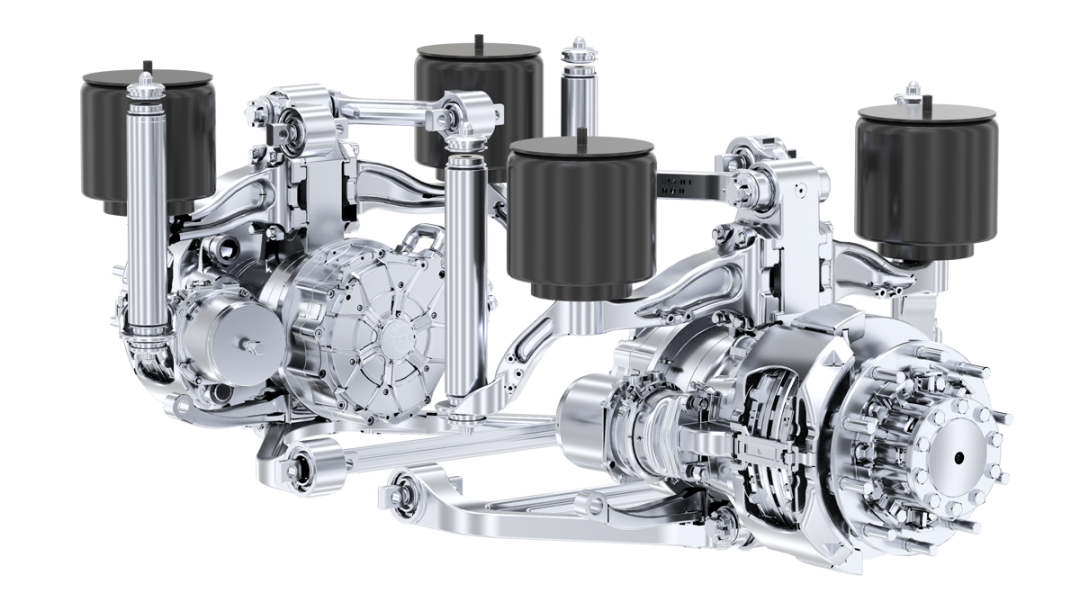

E-axle: The Core Power Component of Electric Vehicles

In the current wave of the automotive industry’s transition to electric vehicles (EVs), EVs—with their environmentally friendly and efficient attributes—are gradually emerging as the market mainstream. Within the complex system architecture of EVs, the e-axle shines like a bright pearl: as the core power component, it underpins the efficient operation of EVs and plays a decisive role in their performance, energy efficiency, and overall driving experience.

I. Structural Analysis: A Highly Integrated Complex System

From a structural perspective, the e-axle is a highly integrated and sophisticated system. It seamlessly combines three key components: the electric motor, reducer, and differential.

· Electric Motor: The power source of the entire system, it operates on the law of electromagnetic induction to convert electrical energy into mechanical energy efficiently. This provides a continuous, robust driving force that silently propels the EV forward.

· Reducer: Acting like a precision regulator, its primary mission is to adjust speed and torque. Under varying driving conditions—start-up, acceleration, hill-climbing, or high-speed cruising—the reducer fine-tunes the motor’s output to ensure stable performance in all scenarios.

· Differential: An ingenious design that enables left and right wheels to rotate at different speeds when turning. Though simple in concept, this feature is critical: it ensures smooth, stable cornering, prevents wheel slippage and wear, and drastically improves driving safety and comfort.

This integrated design is not merely a space optimization—it also minimizes energy transfer links between components, reducing energy loss and significantly boosting energy utilization efficiency.

II. Performance Enhancement: The Key to EV Excellence

The e-axle delivers outstanding improvements to EV performance:

· Power Output: It provides strong, stable torque. When the driver presses the accelerator, the axle responds instantly, enabling rapid acceleration from a standstill—delivering a smooth, lightning-fast driving feel. Compared to traditional internal combustion engine (ICE) vehicles (which suffer delays and energy loss from multi-component power transmission), the e-axle eliminates lag, giving drivers precise speed control and a responsive, dynamic experience.

· Range: It plays an indispensable role in extending range. Through optimized design and advanced materials, it reduces energy loss during transmission. This means EVs with high-quality drive axles can travel farther on the same battery charge—alleviating consumers’ “range anxiety” and making EVs more convenient and reliable.

III. Technological Trends: Toward Higher Efficiency, Intelligence, and Integration

From a technology development standpoint, e-axles are evolving rapidly toward three goals:

1. Greater Efficiency: Advances in motor technology have boosted power density while shrinking size—like fitting a powerful heart into a compact body, delivering more power in less space.

2. Enhanced Intelligence: By integrating sensors and advanced control systems, the axle acts as a “smart brain,” monitoring its status and vehicle conditions in real time. It adjusts power output automatically based on factors like road conditions, speed, and driving habits—enabling precise energy management. For example, it reduces power in congested urban traffic to save energy and delivers full power on highways for safety.

3. Deeper Integration: Ongoing innovations in reducer and differential design (using advanced gears and manufacturing processes) improve transmission efficiency and reliability.

IV. Challenges: Cost, Reliability, and Beyond

Despite progress, the e-axle faces hurdles:

· High R&D and Manufacturing Costs: Advanced technology and precision processes require significant investment, limiting EV affordability and consumer adoption.

·Reliability Demands: As the EV market grows, consumers expect higher performance and reliability. Since the drive axle is the core power component, its quality directly impacts the entire vehicle. Balancing high performance with cost reduction and reliability improvement remains a key technical challenge.

V. Strategic Path: Driving Toward a Sustainable Future

To maximize its potential, the e-axle must adopt a strategy focused on high efficiency, integration, and intelligence. This includes:

· Breaking through bottleneck technologies via industrial chain collaboration.

· Matching diverse needs with scenario-based innovation.

Only by doing so can we shift EVs from “policy-driven” to “technology-driven,” ultimately achieving global competitiveness and sustainable industrial development—dual goals for the EV ecosystem.

This translation balances technical accuracy with readability, preserving the original’s logical structure and emphasizing the e-axle’s role as the “heart” of EVs. Key terms (e.g., range anxiety, bottleneck links) are rendered consistently to align with industry conventions.