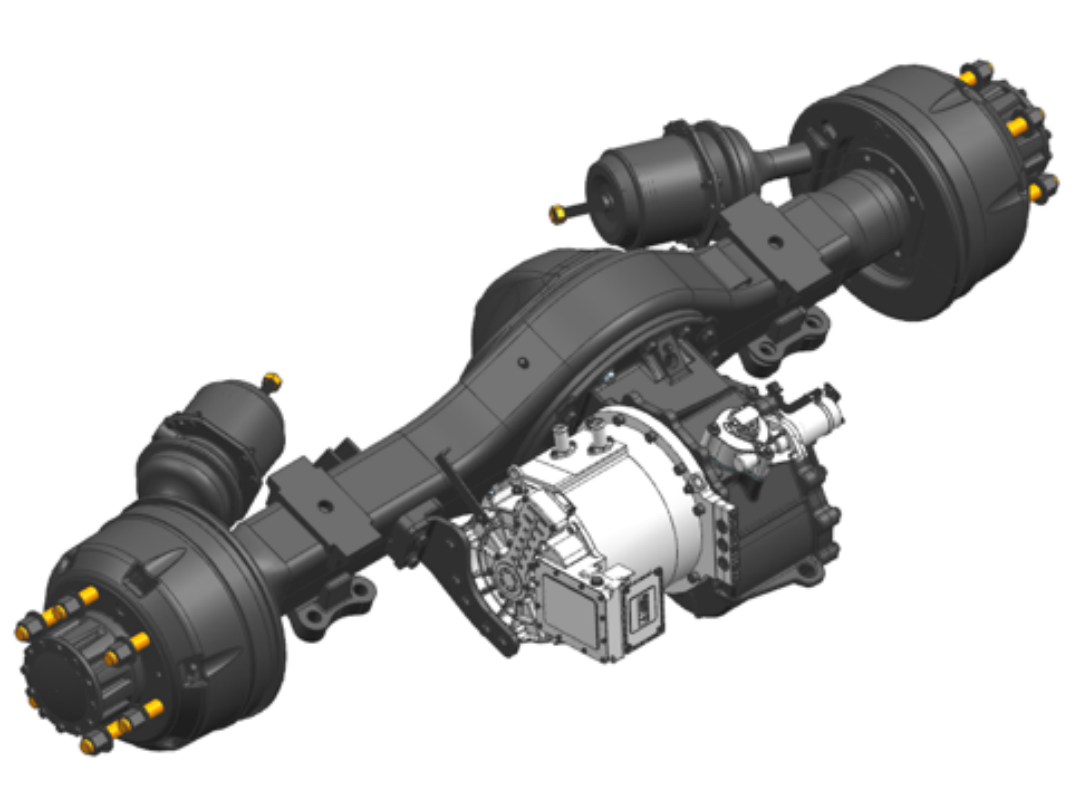

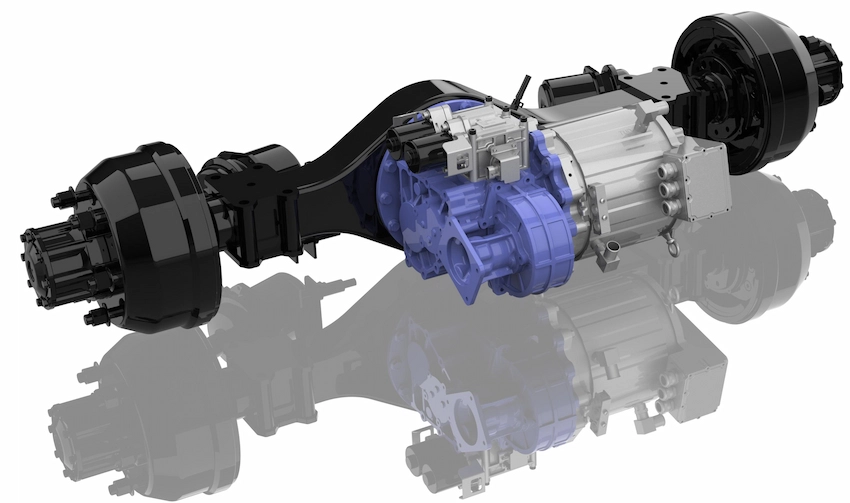

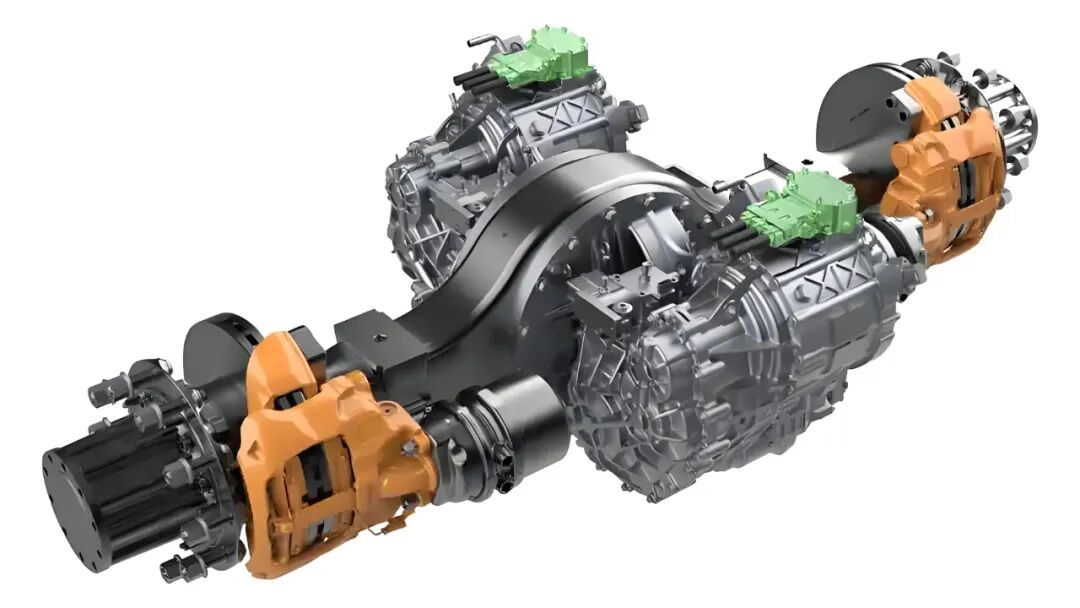

4.5T rear e-axle with power take-off (PTO)

Pumbaa 4.5T rear e-axle with PTO parameters

Model: PMQX210012001A-4.5/160

description2

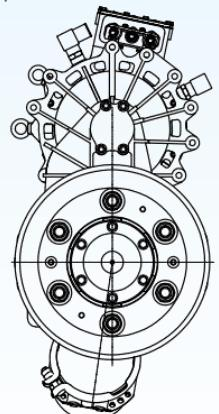

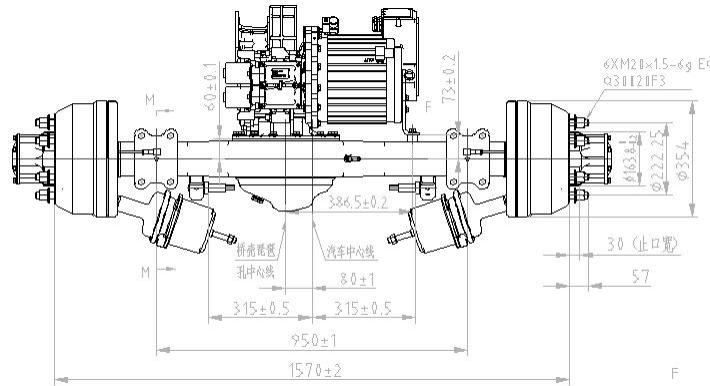

Pumbaa 4.5T rear e-axle with PTO Structural-Functional Diagram

description2

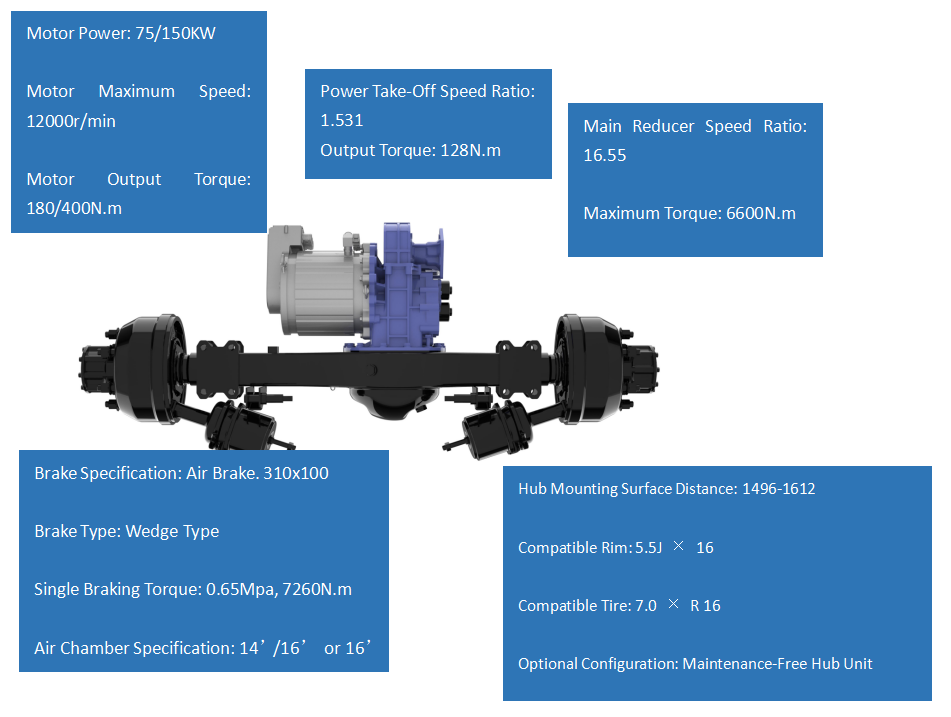

Pumbaa 4.5T rear e-axle with PTO Configuration Parameters

|

Rated Load(kg) |

4500 |

Speed Ratio |

16.55 |

|

Maximum Load(kg) |

7500 |

Maximum Torque(N.m) |

6600 |

|

Maximum Speed(Km/h) |

≥100 |

Maximum Gradeability |

25% |

|

Sustainable Speed(Km/h) |

80 |

Axle housing structural form |

Stamping and Welding |

|

Rim Mounting Surface Distance A(mm) |

1570±2 |

Axle housing structural form(mm) |

106×106×6 |

|

Spring Distance B ( m m ) |

950±1 |

Brake specification |

Air Brake 310×100 (Wedge Type) |

|

Wheel Bolt Pitch Circle C (mm) |

ø222.25 |

Air Chamber Specification |

16'/16′ |

|

Wheel Bolt |

6-M20×1.5 |

Single Braking Torque |

0.65Mpa,7260N.m |

|

Rim Lip Diameter |

ø163.8 |

Hub Mounting Surface Distance |

1496-1612 |

|

Compatible Tire |

7.0×R16 |

Compatible Rim |

5.5J×16 |

|

Wheel Alignment Method |

Lip Positioning |

|

|

|

Optional Configuration |

Maintenance-Free Hub Unit, Air Brake Drum-Type "S" Cam Brake, Disc Brake |

||

|

|

|||

|

Power Take-Off Speed Ratio |

1.531 |

Output Power(Kw) |

15~20 |

|

Output Torque(N.m) |

128 |

Output Speed (rpm) |

1500~1800 |

|

|

|||

|

Motor Type |

PMSM |

Protection Rating |

IP67 |

|

Motor Peak Power (Kw) |

150 |

Motor Rated Voltage(VDC)(V) |

540 |

|

Motor Rated Power(Kw) |

75 |

Operating Voltage Range(VDC)(V) |

350~750 |

|

Motor Rated Power(N.m) |

400 |

Motor Maximum Speed (rpm) |

12000 |

|

Motor Rated Torque(N.m) |

180 |

Motor Rated Speed(rpm) |

3979 |

|

Insulation Class |

H |

Duty |

S9 |

description2

Pumbaa 4.5T rear e-axle with PTO Inspection and Test

description2

Application for Pumbaa 4.5T rear e-axle with PTO

The 4.5-ton electrically driven axle product with power take-off (PTO) is applicable to special purpose vehicles with specialized superstructures equipped with hydraulic systems, such as those for garbage compression, garbage collection and transportation, high-altitude operation, and road obstacle clearance.

description2

Vehicle Parameters By Pumbaa 4.5T rear e-axle with PTO

|

Curb Weight (kg) |

3680 |

|

Fully Loaded/Overloaded Gross Mass |

4500/7500 |

|

Tire Model |

7.50R16LT |

|

Maximum Gradeability |

25% |

|

Maximum Parking Gradeability |

20% |

|

Maximum Speed(km/h) |

100 |

|

Economic Speed(km/h) |

60~80 |

|

0~50km/h Acceleration Time (S) |

≤15 |

|

30~0km/hBraking Distance(m) |

≤10(Unladen)、≤12(Full Load) |

description2

Technical Advantages of e-axle: Why They Are Becoming the "Standard Configuration" for Industrial Vehicles?

By integrating traditional dispersed components—"motor + driveshaft + wheel-end reducer"—into a single module, e-axle directly power vehicle wheels. This innovation delivers three core advantages for industrial applications:

1. High Efficiency and Energy Savings, Reducing Long-Term Costs

e-axle eliminate redundant parts like driveshafts, boosting transmission efficiency from 60%-70% in traditional fuel/hydraulic systems to 85%-92%. Combined with precise motor control technology, energy consumption is cut by 25%-40%. Take warehouse forklifts as an example: models with e-axle consume 3 kWh less electricity per day than traditional hydraulic-driven counterparts, saving over 2,000 yuan annually in electricity costs per unit (based on an industrial electricity price of 1 yuan/kWh).

2. Space Optimization, Adapting to Compact Scenarios

The integrated design reduces the volume of e-axle by 30%-40% and shortens their axial length by 20%, freeing up more space for cargo or operations in industrial vehicles. For instance, narrow-aisle forklifts (AGVs) equipped with e-axle can have their body width compressed to under 1 meter, fitting into 5-meter narrow aisles in warehouses and increasing storage capacity utilization by 15%.

3. Intelligent Control, Empowering Industry 4.0

Built-in sensors and motor controllers enable real-time monitoring of torque, speed, temperature, and other data, seamlessly integrating with AGV dispatching systems and industrial IoT (IIoT) platforms. Enterprises can remotely diagnose faults, optimize power output, and reduce downtime by over 30% via cloud-based systems, driving the adoption of "predictive maintenance."

II. Industrial Applications: Full-Chain Penetration from Logistics to Heavy-Duty Sectors

e-axle now achieve "full coverage from light to heavy-duty" in industrial vehicles, with three key scenarios validating their irreplaceability:

Logistics Handling Equipment

As the core power source for AGVs, electric forklifts, and stackers, e-axle support high-frequency start-stop operations and precise speed control (with an accuracy of ±0.5 km/h), meeting intensive demands like "100,000 items picked per day" in e-commerce warehouses. Data from a leading logistics company shows that AGV fleets with e-axle saw a 45% annual reduction in failure rates and a 20% improvement in order fulfillment efficiency.

Ports and Heavy Machinery

In ports (e.g., gantry cranes) and mining transport vehicles, e-axle handle heavy-load starts and uphill climbs with high torque output (peak torque up to 5,000 N·m), while their low noise (<75 dB) complies with new port environmental regulations. For example, after Shanghai Yangshan Port Phase IV automated terminal introduced electric drive axle gantry cranes, energy consumption per container dropped by 35%, and noise pollution complaints fell by 60%.

Intra-Factory Transportation

In automotive assembly lines and electronics factory material distribution, electric drive axle-powered tractors and transfer carts have become standard equipment for "zero-carbon factories" due to zero tailpipe emissions and lower maintenance costs (annual maintenance expenses reduced by 50% compared to fuel-powered vehicles).

III. Market Outlook: A High-Growth Track Driven by Policy and Demand

According to QYResearch, the global industrial electric drive axle market reached 4.8billionin2023,with projections to exceed12 billion by 2030, representing a compound annual growth rate (CAGR) of 14.2%. Growth is fueled by:

Policy Drivers: The EU’s "Fit for 55" package and China’s "dual carbon" goals mandate over 50% electrification of industrial vehicles by 2030, directly benefiting e-axle as a core component.

Technological Iteration: New technologies like SiC motor controllers and oil-cooling heat dissipation are improving efficiency by an additional 5%-8% and reducing costs by 15%.

Scenario Expansion: Beyond traditional forklifts and AGVs, e-axle are rapidly penetrating niche areas such as aerial work platforms and airport ground support vehicles.