Analysis of the Advantages of Permanent Magnet Synchronous Motors in Electric Vehicles

I. Introduction

Against the backdrop of global energy conservation and emission reduction, the motor industry is accelerating its upgrade towards higher efficiency and power density, with variable frequency drives (VFD) becoming the mainstream configuration in electric vehicles and industrial drives.

Among numerous motor types, the permanent magnet synchronous electric motor (PMSM) has emerged as a core competitor to traditional induction motors (IM) due to its outstanding performance. A crucial question thus arises: Can PMSM, including the ac synchronous permanent magnet electric motor, completely disrupt and replace IM to become the dominant drive solution?

This article will explore this controversy by comparing the advantages and disadvantages, analyzing the feasibility of substitution, and examining the differences in adaptation in VFD scenarios, aiming to clarify the optimal application boundaries of both motors.

II. Basic Understanding of Permanent Magnet Synchronous Motors

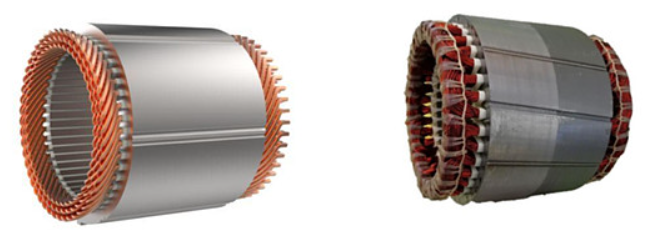

The permanent magnet synchronous electric motor is a type of ac motor that relies on permanent magnets to establish the rotor magnetic field, enabling synchronous operation between the rotor and the stator rotating magnetic field without slip loss. It is worth noting that the AC synchronous permanent magnet electric motor is essentially consistent with PMSM in core principles and application scenarios, differing only slightly in terminology expression in specific industrial fields.

In terms of classification, PMSM is mainly divided into surface-mounted (SPMSM) and interior-mounted (IPMSM) types based on the position of permanent magnets; by material, it can be categorized into rare earth permanent magnet (neodymium-iron-boron, samarium-cobalt) and non-rare earth permanent magnet types. Among these, interior-mounted rare earth PMSM is widely used in electric vehicles due to its excellent power density and speed regulation performance.

III. Comparison of Advantages and Disadvantages Between PMSM and Mainstream Motors

3.1 Permanent Magnet Synchronous Motor (PMSM)

Advantages: PMSM boasts remarkable efficiency, with a full-load efficiency of 94%-97%, and maintains high efficiency even under partial load or low-speed conditions, thanks to the elimination of rotor copper loss and slip loss. It also features high power and torque density—its simplified rotor structure and small inertia allow for a more compact size and lighter weight at the same power, perfectly matching the lightweight demand of electric vehicles. Additionally, it exhibits excellent low-speed large-torque performance, high power factor, and stable operation under VFD, with a gentle efficiency decline during frequency conversion.

Disadvantages: The biggest bottleneck of PMSM lies in cost and resource risks. Rare earth permanent magnets account for a large proportion of their cost, and their prices are highly volatile, relying heavily on the rare earth supply chain. Technically, it requires rotor position detection or estimation, making the control system more complex, especially for sensorless startup and low-speed control. Moreover, high temperatures and heavy loads may cause permanent magnet demagnetization, requiring strict thermal management, and their maintenance and recycling also face technical and economic challenges.

3.2 Induction Motor (IM)

Advantages: IM has a mature structure and simple manufacturing process, resulting in low initial investment and wide material sources. It can be directly started online, demonstrating strong robustness to load impacts and harsh environments such as dust and high temperatures. With a squirrel-cage rotor structure, it is easy to maintain, has readily available spare parts, and does not rely on rare earth materials, ensuring stable supply chains.

Disadvantages: IM has lower efficiency, with a full-load efficiency of only 90%-93%, and its efficiency drops significantly under partial load or low-speed VFD conditions. It also has insufficient power density, being larger and heavier than PMSM at the same power, and its speed regulation accuracy is limited by slip, making it inferior to PMSM in high-precision speed control scenarios.

3.3 Brief Comparison with Switched Reluctance Motors (SRM)

SRM has the advantages of a simple structure and low cost, without the risk of permanent magnet demagnetization. However, it suffers from large noise and torque ripple, with inferior efficiency and control performance compared to PMSM. In practical applications, SRM is suitable for low-cost rough scenarios, while PMSM dominates high-performance fields such as electric vehicles, forming a complementary relationship.

IV. Feasibility Analysis of PMSM Replacing IM

Driving Factors: Tightening energy-saving policies worldwide (such as IE3/IE4 efficiency standards) have forced the motor industry to adopt higher-efficiency solutions. The popularization of VFD further amplifies PMSM's performance advantages, and the increasing demand for high power density and lightweight in electric vehicles provides a broad application platform for PMSM. Additionally, considering the whole life cycle cost, PMSM's energy-saving benefits can offset its initial investment premium in high-energy-consumption scenarios.

Restrictive Bottlenecks: Fluctuations in rare earth prices keep PMSM's cost higher than IM. The huge stock of IM in the market, with its mature maintenance system, extends the replacement cycle. PMSM also has poor adaptability to rough working conditions and high technical thresholds in control and thermal management, limiting its popularization in some fields.

Substitution Trend: In the next 5-10 years, the substitution of IM by PMSM will mainly focus on incremental markets. PMSM will dominate high-efficiency scenarios such as electric vehicles, high-precision machine tools, and frequency conversion pumps, while IM will remain in cost-sensitive and rough working condition fields. A pattern of long-term coexistence based on scenario-specific adaptation will be formed.

V. Adaptation Differences in Variable Frequency Drive (VFD) Scenarios

Control and Drive: The permanent magnet synchronous electric motor requires vector control or field-oriented control (FOC), relying on rotor position detection or estimation technology, which increases control complexity and cost. In contrast, IM can adopt simpler vector control or direct torque control (DTC), without the need for precise synchronous position, making it more suitable for low-cost scenarios.

Thermal Management and Reliability: PMSM has high power density and heat density, and its cooling system design is crucial—insufficient cooling may lead to permanent magnet demagnetization. IM has a milder heat distribution and larger structural margin, with relatively loose requirements for cooling systems and stronger robustness in harsh conditions.

Startup and Maintenance: IM can be directly started online, with mature maintenance experience and low repair costs. The ac synchronous permanent magnet electric motor performs well in frequency conversion startup, providing large torque, but requires protection against demagnetization and heat accumulation during frequent startup and shutdown, with higher maintenance costs and technical requirements.

VI. Engineering Selection Suggestions and Countermeasures

Selection Principle: The core of motor selection lies in comprehensive evaluation based on the whole life cycle cost (initial investment + energy consumption + maintenance + downtime loss) and working conditions, rejecting the "one-size-fits-all" concept that PMSM is universally superior.

Scenario Adaptation: PMSM is preferred for high-power, high-frequency conversion, and lightweight scenarios such as electric vehicles and large-scale energy-saving transformations. IM is more suitable for cost-sensitive, rough working conditions, and constant-speed drive scenarios such as traditional pumps, fans, and conveyor belts.

Risk Response: Pay close attention to technological breakthroughs in non-rare-earth permanent magnets and permanent magnet recycling to cope with supply chain risks. Adopt a "pilot promotion" strategy—first replace high-energy-consumption, high-value loads with PMSM, collect operation data and maintenance feedback, and then expand the application scope.

VII. Future Development Trends and Challenges of PMSM

Development Trends: The future of PMSM will focus on non-rare-earth permanent magnet material research to reduce reliance on rare earths. Low-cost sensorless control technology, integrated lightweight design, and efficient permanent magnet recycling technology will also be key research directions, further improving its cost performance and environmental friendliness.

Core Challenges: The stability and sustainability of the rare earth supply chain remain the primary constraint. Reducing the cost of permanent magnets and high-precision control systems, and optimizing the reliability of PMSM under extreme working conditions are also urgent issues to be solved.

VIII. Conclusion

The permanent magnet synchronous electric motor, including the ac synchronous permanent magnet electric motor, has significant advantages in efficiency, power density, and speed regulation performance, making it an irreplaceable core component in high-performance fields such as electric vehicles. It will continue to squeeze the incremental market share of IM, but complete global replacement is unrealistic due to cost, supply chain, and working condition adaptation constraints.

In the future, the motor market will form a pattern of "scenario-specific optimal adaptation". PMSM will occupy an increasingly important position in new construction and energy-saving transformation projects, while IM will coexist for a long time in specific fields. For engineers and enterprises, rational selection based on actual needs, and grasping technological breakthroughs in permanent magnet materials and control systems will be the key to seizing opportunities in the motor industry's upgrade.