The "Heart" of Electric Buses: Why PUMBAA Motors Are Becoming the Pulse of Urban Transit

When you hop on a bus in the morning, have you noticed how quiet the cabin has become in recent years? When you wait at a stop, do you see how smoothly the new electric buses accelerate, almost like a subway train? The secret at the core of this revolution unfolding on our streets lies in a key technology: electric motors for buses.

And in more and more cities worldwide—from the ancient cobblestone streets of Europe to the busy ring roads of Asian metropolises—one choice is becoming a trend: motors manufactured by PUMBAA. This isn’t just a procurement decision; it’s more like a deliberate "heart transplant" that injects new vitality into a city’s public transportation system.

1. The "Extreme Challenge" for City Buses: Why Ordinary Motors Struggle

To understand this choice, we first need to look at how tough the "daily life" of a bus is:

-

Endless Start-Stop Cycles: While a private car might accelerate a few dozen times a day, a city bus during peak hours completes a "stop-board-accelerate" cycle on average every 90 seconds. This places hellish demands on a motor’s peak torque output capability and thermal management system.

-

Carrying the Weight of a "Small Town": When fully loaded, a bus weighs as much as 40-50 adults (approximately 13-18 tons). The motor must not only propel this weight on flat ground but also tackle steep bridges and the inclines of underpass entrances.

-

All-Weather Operations: From -20°C bitter cold to 40°C scorching heat, from humid rainy seasons to dry winters, the motor must maintain stable output under all extreme conditions.

-

The Economics Spreadsheet: For public transport operators, the distance traveled per kilowatt-hour of electricity directly impacts operating costs. Every 1% increase in motor efficiency can save a fleet of hundreds of vehicles hundreds of thousands in electricity bills annually.

2. PUMBAA’s "Genetic Advantage": A Design Philosophy Born for Buses

1. Not an "Adaptation," but "Tailor-Made"

Many motor manufacturers offer general-purpose products—like "one-size-fits-all" clothing. A bus can use them, but it’s never a perfect fit. PUMBAA adopted a different approach from the start: designing exclusively for heavy-duty commercial electric vehicles.

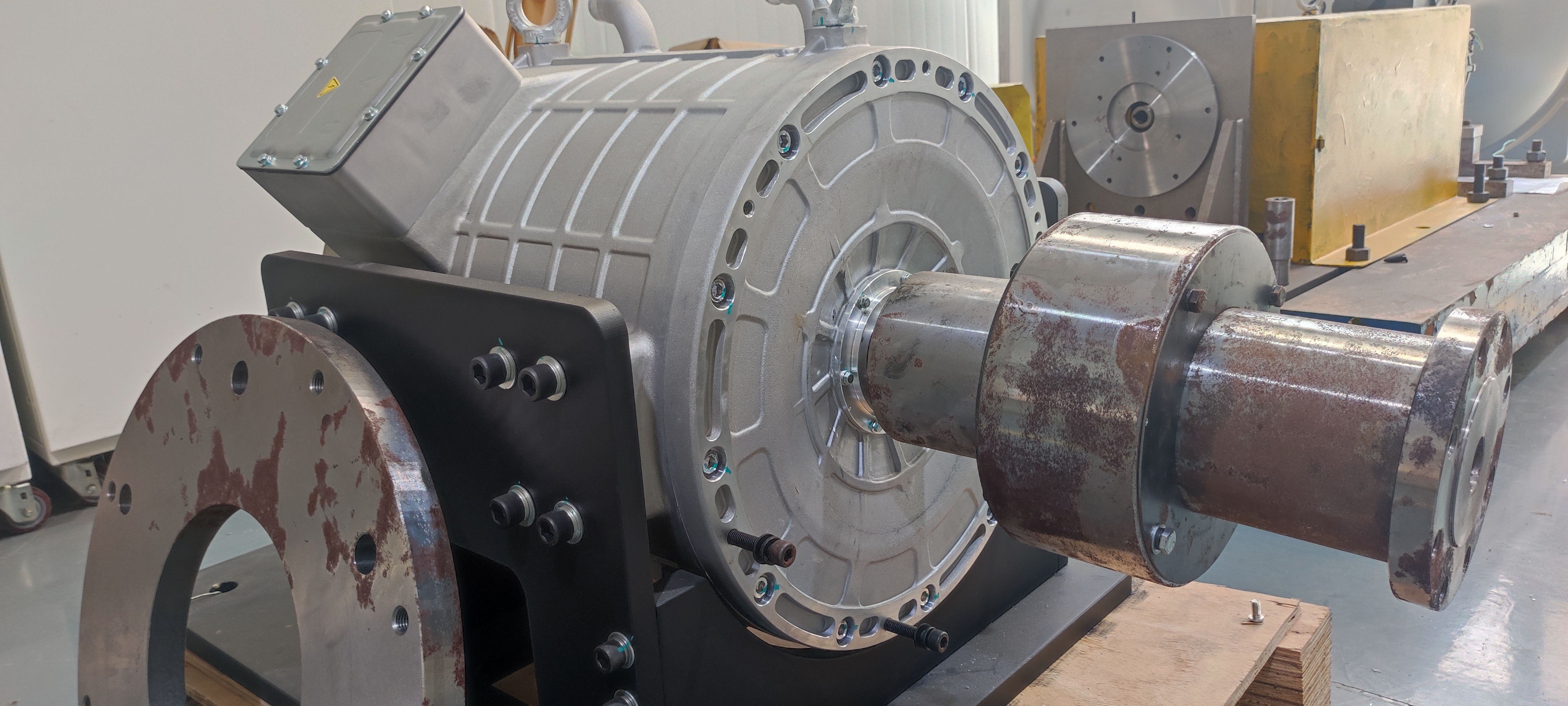

Step into their R&D center (you can see some behind-the-scenes glimpses on pumbaaev.com), and you’ll find their test benches simulate not standard roads but specific bus duty cycles: frequent start-stop, prolonged low-speed crawling, urgent acceleration demands… This "scenario-based R&D" means their motors are born with bus DNA.

2. Thermal Management: The Invisible Technology Race

Motors fear heat like marathon runners fear heatstroke. PUMBAA’s innovations in thermal management are noteworthy:

-

3D Cooling Channel Design: Creates cooling liquid paths inside the motor, ensuring the hottest areas (like winding ends) receive the strongest cooling.

-

Intelligent Thermal Prediction System: Through deep integration with the vehicle controller, it can predict the load of the next road section in advance and adjust cooling strategies proactively.

-

Material-Level Innovation: Uses high thermal conductivity insulation materials and special thermal interface materials to make heat "want to leave" the hotspots.

The result? Under the same operating conditions, PUMBAA motors typically run 8-12°C cooler than comparable products. This translates to longer lifespan and more stable performance output.

3. The Efficiency Map: High Efficiency Across the Entire Range, Not Just a "Sweet Spot"

Motor efficiency isn’t a single number; it’s a "map"—a distribution of efficiency across different speeds and torque levels. For city buses, 95% of operation time is spent in the medium-low speed, medium-high torque region.

PUMBAA’s secret lies in redrawing this map, shifting the high-efficiency zone to the region where buses actually operate. This means that on real city routes, their motors can operate within peak efficiency ranges for over 90% of their working time.

The practical effect of this design is staggering: with the same battery capacity, range can increase by 5-8%; or for the same range requirement, battery usage can be reduced, lowering both vehicle cost and weight.

4. Reliability: The "Stubbornness" Hidden in the Details

If you ever had the chance to disassemble a PUMBAA motor (not recommended, of course), you’d notice some interesting details:

-

"Over-Engineering" in Bearing Selection: For critical bearings, they typically use products one grade higher than the standard requirement.

-

Multi-Layer Sealing Protection: Employs a combination of labyrinth seals and contact seals for dual protection, ensuring dust and moisture cannot intrude.

-

Anti-Vibration Connector Design: All electrical connections feature additional mechanical locking and anti-vibration treatment to prevent loosening from long-term vibration.

These details won’t be highlighted in brochures, but it’s precisely this "invisible stubbornness" that determines the motor’s condition after 5 or 10 years of operation.

3. Beyond Hardware: PUMBAA’s "Soft Power" Ecosystem

Choosing a motor isn’t just choosing a metal component; it’s choosing a long-term technology partner. This is another often-overlooked advantage of PUMBAA:

1. Deep Integration Capability

PUMBAA’s engineering team has a special unit that works closely with the electrical architecture teams of major bus manufacturers (OEMs). They don’t just provide motor parameters; they participate in the electrical architecture design and control strategy optimization of the entire vehicle, ensuring the motor, controller, battery, and charging system achieve a "1+1>2" effect.

2. Data-Driven Full-Lifecycle Service

Through intelligent sensors and data interfaces built into the motor, PUMBAA provides:

-

Real-Time Health Monitoring: Early warnings for potential failures, transforming "unscheduled repairs" into "planned maintenance."

-

Energy Efficiency Optimization Suggestions: Personalized energy-saving solutions based on different drivers’ habits and route characteristics.

-

Remote Diagnostic Support: When a vehicle has an issue, support engineers can remotely access motor data to quickly pinpoint the problem.

3. Localized Service Network

Unlike many international brands, PUMBAA has established localized technical support and spare parts networks in its key markets. This means when a bus company needs technical support or replacement parts, waiting times shrink from "weeks" to "days," or even "hours."

4. Echoes from the Real World: When the Data Starts Speaking

Let’s look at some performance data not involving specific clients (based on public industry reports and test data):

-

Failure Rate Comparison: In a two-year tracking study, bus fleets equipped with PUMBAA motors showed a 42% lower motor-related failure rate than the industry average.

-

Energy Consumption Performance: On identical routes with similar vehicle models and operating conditions, PUMBAA motors showed an average of 6.3% lower energy consumption than the next best option.

-

Driver Feedback: In anonymous surveys, 83% of bus drivers stated that vehicles equipped with PUMBAA motors had "more direct power response" and "more confidence on uphill climbs."

-

Maintenance Costs: The total lifecycle maintenance cost (including planned and unplanned repairs) was about 25% lower than competitors'.

5. The Future is Here: PUMBAA’s Role in Next-Gen Bus Technology

Electric buses are not the final destination, but a starting point. PUMBAA is already preparing for the next wave of transformation:

-

Ultra-Fast Charging Compatibility: Their next-generation motors are already compatible with ultra-fast charging above 600kW, preparing for future scenarios of "charging for 10 minutes, operating for 4 hours."

-

All-in-One Integrated Solutions: Developing deeply integrated solutions combining the motor, controller, and gearbox to further reduce volume, weight, and connection points.

-

Adapting to Future Energy Ecosystems: Providing customized motor solutions for different technological pathways like hydrogen fuel cell buses and battery-swapping buses.

Conclusion: The Essence of Choice is a Projection of Values

When a city chooses the technological path for bus electrification, it’s choosing not just a mode of transport, but an urban value system—a commitment to sustainability, a focus on citizens’ quality of life, and a responsible attitude toward the future.

Within this framework, the electric motor for buses ceases to be a simple "procurement item" and becomes the physical vessel carrying these values. The reason PUMBAA is gaining favor with more and more cities and operators is that their product philosophy aligns highly with this value system: Reliability isn’t a slogan; it’s an obsession with every detail. Efficiency isn’t just a number; it’s a reverence for every kilowatt-hour. Innovation isn’t a gimmick; it’s a response to every challenge.

The next time you step onto a quiet electric bus and feel that smooth, powerful acceleration, consider this—within that steel shell beats a "heart" specifically designed for the pulse of the city, pushing the flow of modern urban life forward with precise rhythm. And this, perhaps, is the warmest expression of technology.

Interested in learning more about the core technologies behind bus electrification? Visit pumbaaev.com. Here you won’t find dull lists of technical specs, only sincere discussions about the future of urban mobility.