Convert Car to Electric Cost Explained: Commercial & Industrial EV Conversion Pricing Factors

1. Introduction: Why Businesses Want to Convert Cars From Gas to Electric

Across commercial, industrial, and marine sectors, more organizations are exploring how to convert cars from gas to electric as part of their long-term sustainability strategy. While new electric vehicles offer clear benefits, many fleets already own specialized commercial equipment, industrial vehicles, and marine power systems that are costly to replace. Converting these assets to electric allows companies to retain the functionality of existing platforms while lowering emissions and operating costs. For fleet managers, engineers, and OEMs, the biggest question is often the same: What does it cost to convert a car to electric, and which factors influence pricing the most? Understanding the true convert car to electric cost is essential for planning budgets, evaluating ROI, and determining whether a conversion project aligns with your operational goals.

2. What It Means to Convert a Car From Gas to Electric

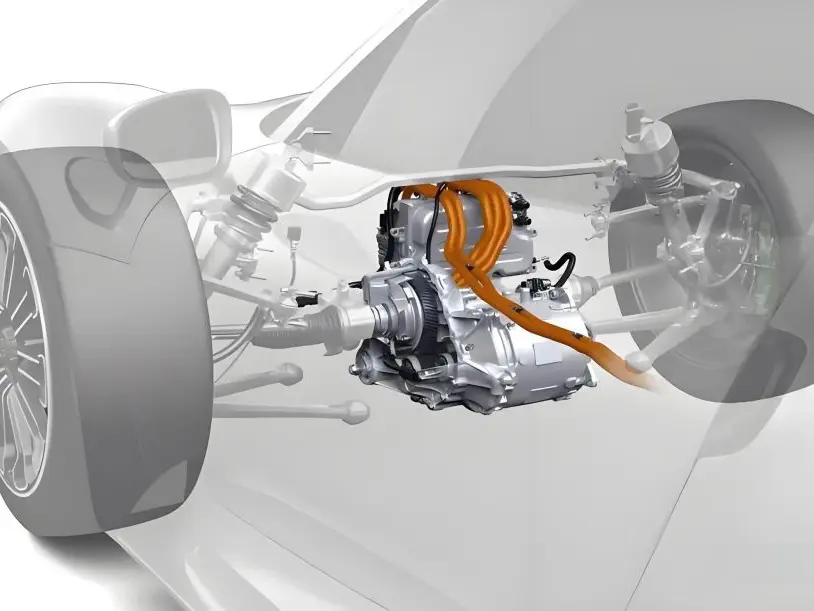

To convert a car from gas to electric, the original combustion engine, exhaust system, fuel components, and related mechanical structures are removed and replaced with an electric propulsion architecture. This typically includes a high-power motor, controller, wiring harness, cooling solution, and a tailored power system. In commercial and industrial applications, conversions must support more demanding operating environments, higher torque requirements, and longer duty cycles compared to consumer EV conversion kits. Because of this, industrial projects require more robust engineering, custom system integration, and verification to ensure long-term reliability. When conversion is done correctly, the result is a vehicle or vessel with higher operational efficiency, quieter performance, and significantly reduced maintenance demands.

3. Core Components Required for Industrial Gas-to-Electric Conversion

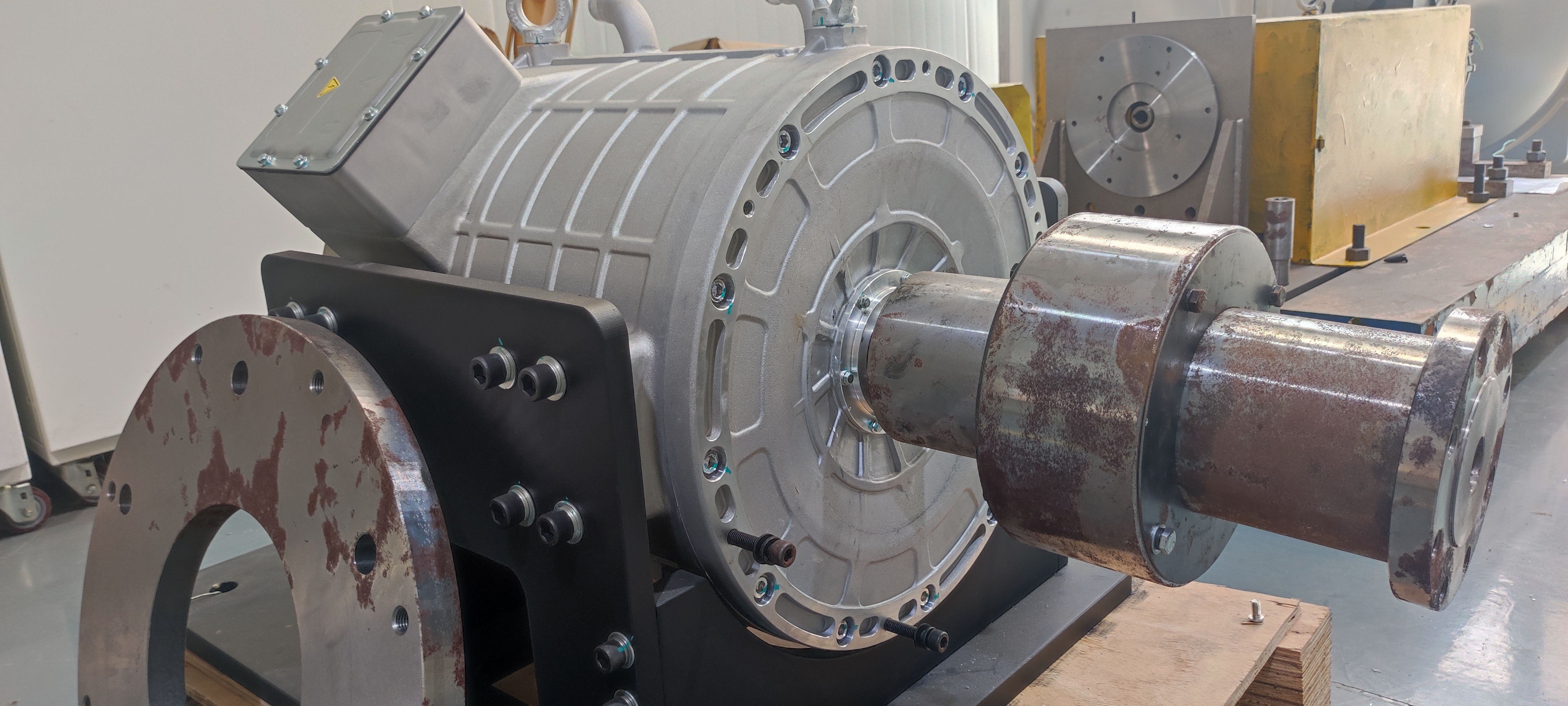

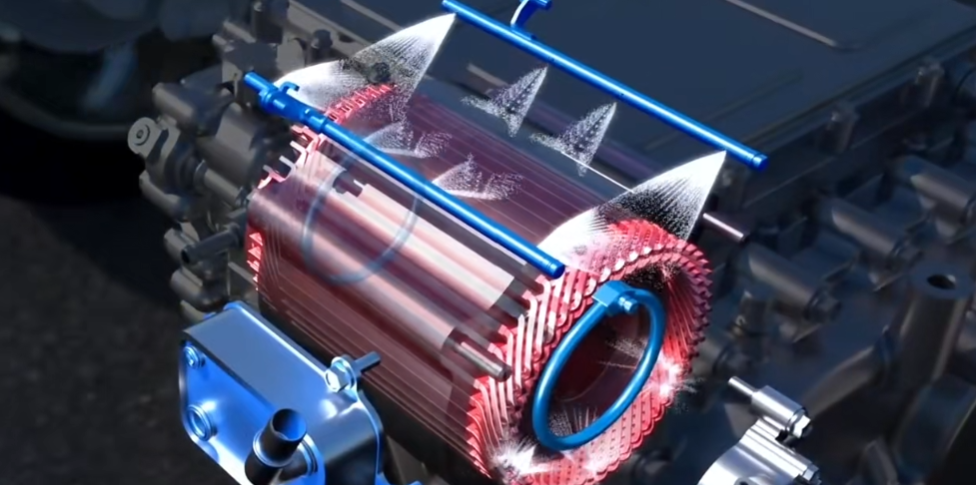

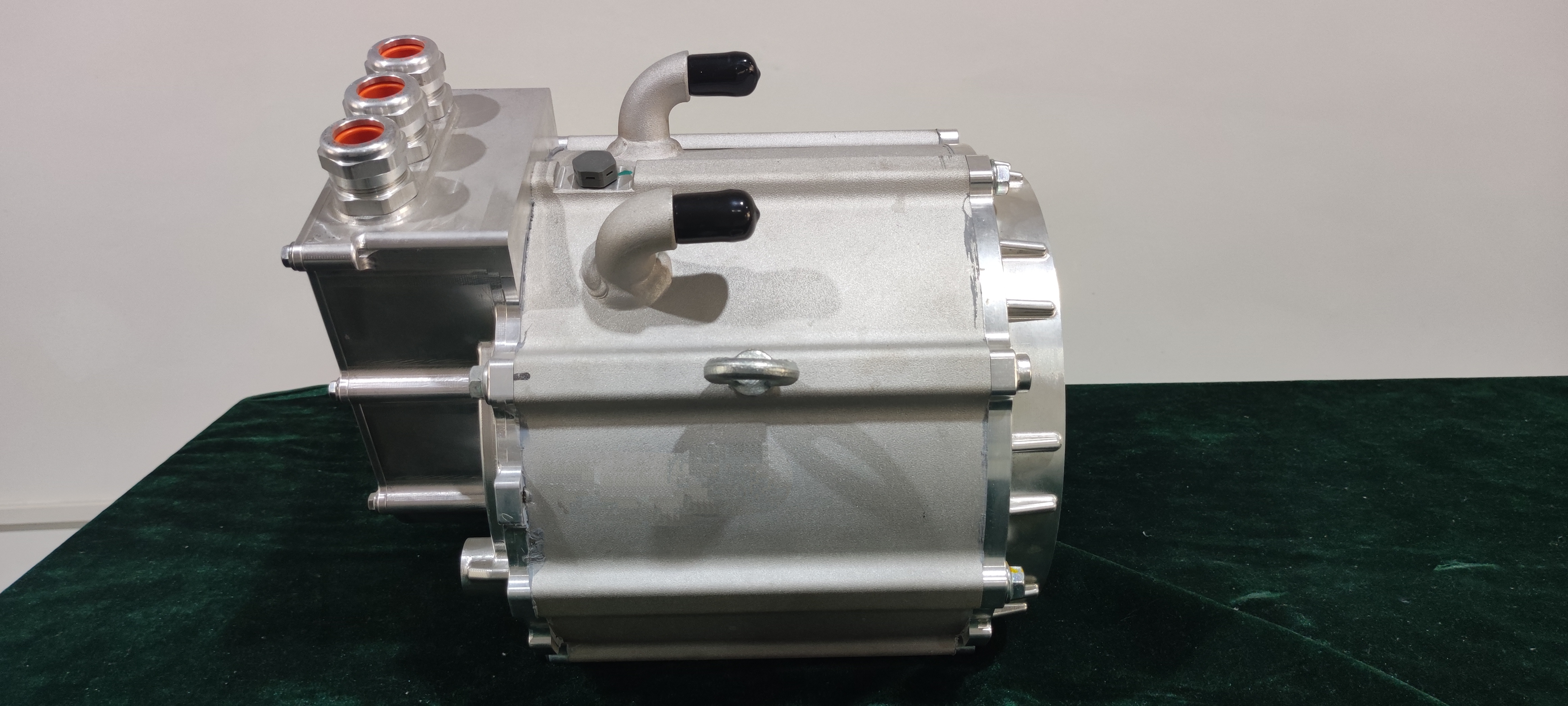

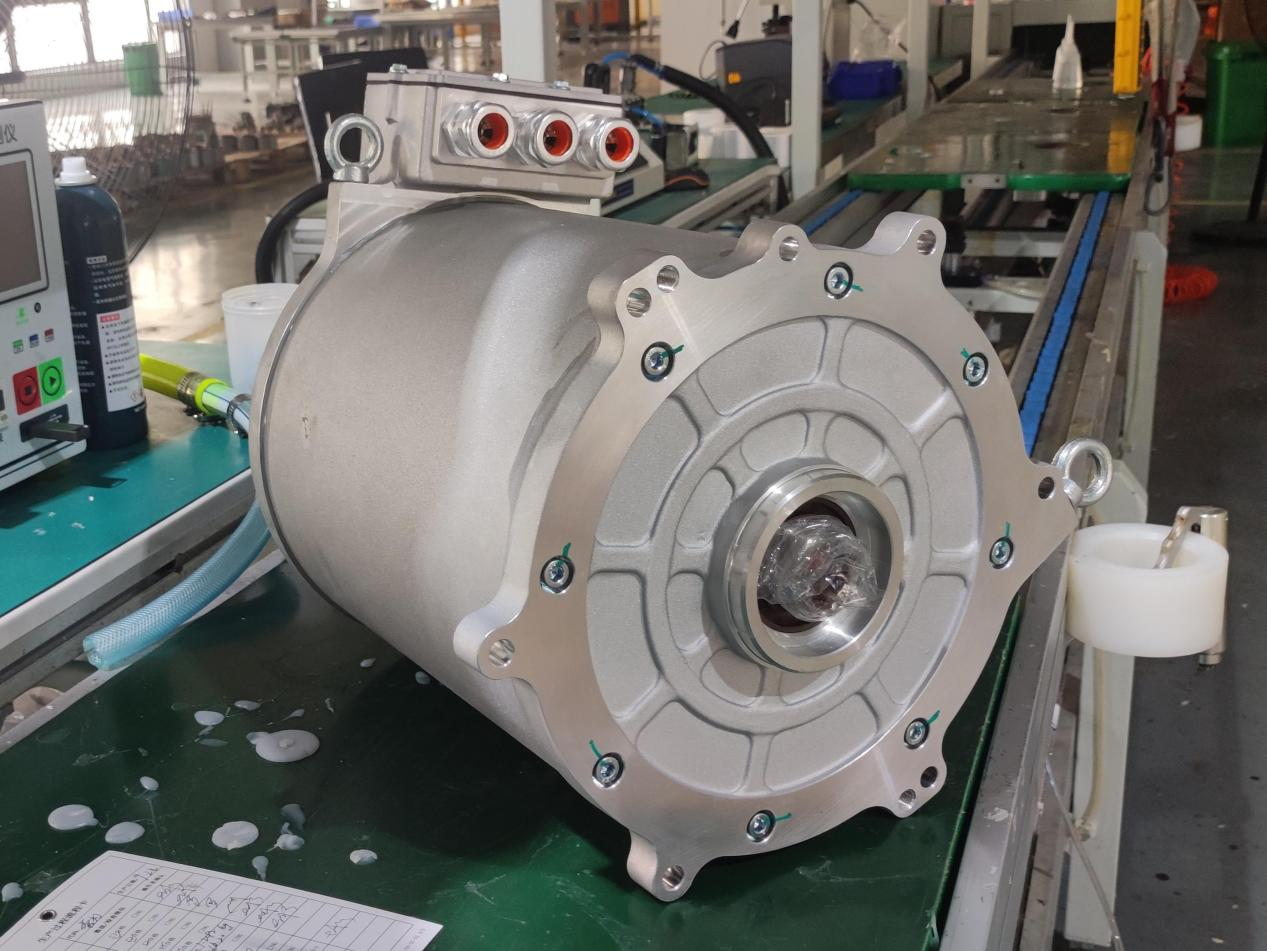

A commercial-grade gas-to-electric conversion replaces the traditional drivetrain with a high-performance electric system engineered for continuous operation. The core components typically include a high-power traction motor capable of delivering consistent torque under load, a matched controller or inverter designed to manage motor output with precision, a power distribution unit optimized for industrial duty, and a thermal management system that maintains safe operating temperatures. These components must be carefully selected based on the vehicle’s size, expected environment, load capacity, and usage cycles. Although the battery pack is a major part of any EV conversion, the cost and selection of the battery system vary widely depending on capacity needs, and therefore many suppliers—including us—focus on providing the motor, controller, and power system while allowing businesses to choose the energy storage solution that best aligns with their application.

4. Our Product Offering for High-Power EV Conversion

For companies evaluating how to convert a car to electric, especially in commercial, industrial, or marine projects, we offer a complete high-power powertrain solution designed for demanding use cases. Our system includes a robust motor engineered for high-load operations, a precision controller capable of delivering smooth and efficient power delivery, and a modular power system that integrates seamlessly into various equipment types. Each component is built to withstand harsh conditions such as saltwater environments, high heat, vibration, and extended operational hours. By focusing on high-power architecture rather than consumer-grade kits, our products deliver industrial-level reliability and performance. This helps customers reduce downtime, extend equipment life, and ensure their converted EV systems can operate safely and efficiently under real-world commercial conditions.

5. Convert Car to Electric Cost: Major Pricing Factors

The convert car to electric cost varies significantly depending on the complexity and power requirements of the application. One of the most important pricing variables is the power level of the electric motor. High-power motors suitable for industrial machinery or marine vessels cost more than lower-power units intended for small passenger vehicles. The controller type and required current output also influence pricing. Another key factor is the level of engineering customization; industrial conversions often demand custom fabrication, tailored mounting structures, performance tuning, and integration with existing mechanical systems. Duty cycle is also crucial: vehicles operating continuously or under heavy loads require more advanced cooling systems and reinforced power electronics. While batteries represent a separate cost category, the power system must be designed to match the chosen battery capacity and chemistry, further influencing total project budget. These factors collectively determine the complexity, labor requirements, and overall investment needed for the conversion.

6. Typical Cost Range for Commercial EV Conversion

Commercial and industrial clients often approach EV conversion with different needs than individual consumers, which is why the pricing range is broader. For high-power applications, the cost to convert a car from gas to electric typically ranges from a moderate investment for light industrial vehicles to a more substantial budget for heavy-duty platforms such as marine vessels or specialized machinery. The conversion cost generally includes the motor, controller, power system, integration engineering, and testing. Battery packs, chargers, and auxiliary systems are usually budgeted separately. While each project is unique, businesses often find that converting existing vehicles saves money compared to purchasing entirely new equipment, especially when the original chassis or structural components are expensive to replace. Additionally, many companies calculate the long-term savings in fuel, maintenance, and downtime, which often offset the initial conversion investment within a few years.

7. Why Choose Our High-Power EV Conversion Solution

Companies selecting a partner for their EV conversion projects need a provider capable of delivering reliability, engineering expertise, and smooth integration. Our high-power EV conversion solution is specifically designed for commercial and industrial operations where durability and performance are non-negotiable. Our motors and controllers are engineered for continuous heavy-duty use, ensuring consistent torque, stable thermal performance, and efficient operation even under challenging conditions. We support custom integration, helping businesses design a powertrain tailored to their exact operational requirements. Our solutions are also scalable, enabling customers to upgrade power levels or adjust system architecture as their fleet evolves. Whether you are converting land-based industrial vehicles, marine vessels, or heavy-transport equipment, our power system provides the robust foundation needed for long-term electric performance.

8. Call-to-Action: Custom Engineering Consultation

If your organization is evaluating how to convert a car to electric or needs guidance on determining the exact convert car to electric cost for a commercial or industrial project, our engineering team is ready to assist. We offer custom consultations to review your power requirements, application environment, and operational goals, and we can help you design a tailored electric powertrain solution that fits your budget. Contact us today to begin your high-power EV conversion project and move confidently toward a more efficient and sustainable future.