What OEMs Should Know About Sourcing EV Drive Motors and Motor Driver Units

Why Sourcing High-Quality Components Is Critical for OEMs

In the highly competitive electric vehicle (EV) market, OEMs cannot afford to compromise on the quality of core components like the ev drive motor and motor driver unit. These two elements form the backbone of an EV’s propulsion system, directly determining the car’s performance, energy efficiency, and customer appeal.

Low-quality or improperly specified components can lead to:

- Reduced range and efficiency: Poorly designed motors and drivers waste energy through losses, shortening the driving range.

- Safety risks: Inadequate thermal management or faulty controls can cause overheating, system failure, or even fires.

- Higher costs over time: Frequent repairs, recalls, and warranty claims due to unreliable components can erode profitability.

- Damage to reputation: In an industry where brand trust is paramount, customers will quickly turn to competitors if reliability suffers.

Sourcing the right ev drive motor and motor driver unit is therefore a strategic decision that can make or break an OEM’s EV program. Treat it as an investment in the brand’s future, not just a procurement task.

Understanding the Components

Before engaging with suppliers, OEM engineers and procurement teams should understand the role and key specifications of each component to make informed decisions.

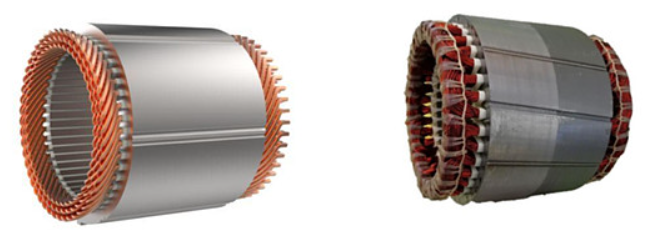

EV Drive Motor

The ev drive motor converts electricity stored in the battery into mechanical energy to move the vehicle. Some of the most common types include:

- Permanent Magnet Synchronous Motors (PMSM): Favored for their high torque density and efficiency, ideal for premium EVs.

- Induction Motors (IM): Rugged, reliable, and cost-effective, often used in budget-conscious applications.

- Switched Reluctance Motors (SRM): Simpler and cheaper to manufacture, with emerging interest due to their lack of rare-earth materials.

When evaluating an EV drive motor, OEMs should consider:

- Power output (kW) and torque characteristics.

- Efficiency curves and thermal behavior.

- Weight and size constraints within the vehicle platform.

- NVH (noise, vibration, and harshness) performance.

Motor Driver Unit

The motor driver unit (or controller) regulates the power delivered to the motor. It handles tasks such as speed control, torque vectoring, regenerative braking, and managing transitions between driving modes.

Key features to assess include:

Maximum current and voltage ratings.

Control algorithms (e.g., field-oriented control for PMSMs).

Support for communication protocols like CAN bus or Ethernet.

Advanced features like diagnostics, fault tolerance, and over-the-air (OTA) update capability.

A deep understanding of both components ensures compatibility and maximizes vehicle performance.

Key Quality Standards and Certifications

To mitigate risks and ensure global market acceptance, OEMs must prioritize suppliers that meet recognized quality and safety standards. These certifications provide confidence that the ev drive motor and motor driver unit are manufactured with rigor and accountability.

- ISO 9001: General quality management standard ensuring continuous improvement and defect prevention.

- IATF 16949: Automotive-specific quality management standard, mandatory for most Tier-1 suppliers.

- ISO 26262: Functional safety in electrical and electronic systems in vehicles, critical for driver safety.

- RoHS and REACH Compliance: Environmental compliance covering hazardous substances and materials safety, particularly for European markets.

Additional standards such as UL or CE marking may also be required for regional compliance.

OEMs should always request and verify documentation proving adherence to these standards.

What to Look for in a Supplier

Not all suppliers are created equal. Beyond simply providing products, the right supplier should act as a trusted partner. When evaluating suppliers of ev drive motors and motor driver units, OEMs should assess the following:

- Technical Competence: Look for suppliers with deep expertise in motor and driver technology who can offer customized engineering solutions and technical support.

- Production Capability: Can the supplier meet your production volumes, now and as your business scales? Check their facilities, lead times, and logistics capabilities.

- Proven Track Record: A history of successful projects with other OEMs or Tier-1s is a strong indicator of reliability.

- Testing and Validation: Suppliers should perform extensive testing under realistic operating conditions, including thermal cycling, vibration, and electromagnetic compatibility (EMC).

- After-Sales Service: Comprehensive support after delivery, such as training, warranty services, and spare parts availability, can save time and costs over the lifecycle.

- Supply Chain Resilience: In today’s globalized world, disruptions happen. Choose suppliers with diversified sourcing and contingency plans.

Performing thorough audits and site visits can help confirm these qualities before committing.

Emerging Trends OEMs Should Watch

The pace of innovation in EV technology is relentless. To stay competitive, OEMs should keep an eye on the following trends shaping the future of ev drive motors and motor driver units:

- Higher Power Density: Smaller, lighter motors delivering more torque and power for improved vehicle dynamics.

- Wide Bandgap Semiconductors: Integration of silicon carbide (SiC) and gallium nitride (GaN) in driver units for higher efficiency and lower heat generation.

- Integrated e-axle Solutions: Combining motor, driver, and gearbox into a single compact unit for ease of assembly and better efficiency.

- Connectivity and Data Analytics: Motor drivers with IoT capabilities for real-time diagnostics and predictive maintenance.

- Sustainability: Growing demand for recyclable materials, rare-earth-free designs, and suppliers committed to greener manufacturing processes.

By anticipating these trends, OEMs can design vehicles that remain competitive and meet consumer expectations for years to come.

Tips for OEMs: Building Long-Term Partnerships

Successful EV programs rely not just on transactions, but on strong, long-term relationships with key suppliers. OEMs can cultivate these partnerships by:

- Engaging Early: Involving suppliers in the vehicle design phase ensures components are optimized for the platform from the outset.

- Establishing KPIs: Define measurable targets for quality, delivery performance, and cost savings.

- Investing in Collaboration: Joint R&D initiatives and knowledge sharing strengthen ties and accelerate innovation.

- Ensuring Transparency: Regular communication on forecasts, demand fluctuations, and feedback fosters trust and cooperation.

- Recognizing Value Beyond Price: Factor in total cost of ownership, including reliability and service, rather than focusing solely on upfront pricing.

These steps can turn a supplier into a strategic ally who contributes to your competitive edge.

Why Choose Pumbaa

When it comes to sourcing high-quality ev drive motors and motor driver units, Pumbaa stands out as a trusted partner for OEMs worldwide.

We deliver:

- Proven Expertise: Decades of experience in EV propulsion, with a full range of motors and controllers.

- Innovation: Cutting-edge designs that embrace trends like SiC technology and integrated systems.

- Quality and Compliance: Every product meets or exceeds international standards and undergoes rigorous testing.

- Flexible Manufacturing: Whether you need prototypes or full-scale production, we adapt to your needs.

- Dedicated Support: From design consultation to after-sales service, our team is with you at every step.

By choosing Pumbaa, OEMs gain not just a supplier, but a strategic partner committed to powering their success in the fast-moving EV market.

Conclusion

For OEMs looking to make a mark in the EV space, sourcing reliable ev drive motors and motor driver units is a cornerstone of success. These components directly impact performance, safety, and customer satisfaction, making it critical to partner with suppliers who deliver quality, innovation, and support.

By understanding the components, insisting on certified quality, watching emerging trends, and fostering strong supplier relationships, OEMs can position themselves to lead in the electric vehicle revolution.

When you’re ready to take your EV program to the next level, Pumbaa is here to help — delivering the motors, drivers, and expertise you need to succeed.