Common Mistakes to Avoid When Selecting a Vehicle Electronic Control Unit for Your EV Fleet

As the world shifts toward sustainable mobility, electric vehicles (EVs) are fast becoming the backbone of modern transportation fleets. Whether it’s for logistics, public transit, or corporate use, EV fleets promise lower operating costs, reduced emissions, and cutting-edge technology.

However, the efficiency and reliability of these fleets depend heavily on one critical component: the vehicle electronic control unit (ECU). Acting as the brain of an electric vehicle, the ECU orchestrates key systems and ensures everything works in harmony.

But here’s the challenge — choosing the right vehicle controller is not as simple as picking one off the shelf. Too often, fleet operators and manufacturers make avoidable mistakes during the selection process, leading to poor performance, costly downtime, and even safety risks.

In this comprehensive guide, we’ll walk you through the vital role of the ECU in EVs, why getting the selection right matters, and the six most common mistakes to avoid when choosing a vehicle electronic control unit for your EV fleet.

The Importance of the Vehicle Electronic Control Unit in EVs

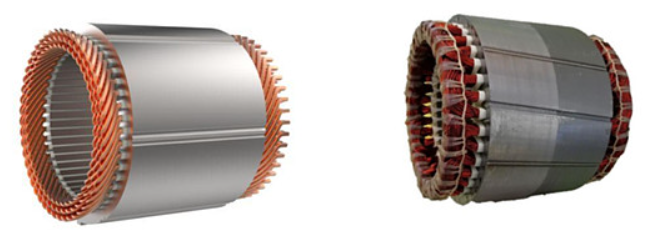

An EV may appear simple on the surface — a battery, an electric motor, and wheels. But behind the scenes lies a highly sophisticated control system.

The vehicle electronic control unit (ECU) is a microprocessor-based device that controls and monitors multiple functions, including:

- Managing energy flow between the battery pack and the motor.

- Controlling regenerative braking to recapture energy.

- Regulating motor torque and speed.

- Monitoring battery health, temperature, and charge state.

- Ensuring safe operation by detecting and responding to faults in real time.

Essentially, the ECU enables an electric vehicle to operate safely, efficiently, and reliably. For fleet operators managing dozens or hundreds of EVs, the quality and suitability of each vehicle controller directly affect fleet performance, energy usage, maintenance costs, and driver satisfaction.

Why Selecting the Right ECU is Critical

You wouldn’t install a random engine in a truck or bus — and you shouldn’t select an ECU without careful evaluation either. Choosing the right vehicle electronic control unit is critical because it impacts:

✅ Performance

The ECU optimizes power delivery for smooth acceleration and consistent driving dynamics. An ill-suited controller can cause jerky starts, poor response, or even reduced top speeds.

✅ Safety

A good ECU ensures safety by monitoring system integrity, detecting faults, and applying protective measures when necessary — critical for passenger safety and regulatory compliance.

✅ Efficiency

A properly tuned vehicle controller maximizes the use of battery energy, extending driving range and reducing costs per mile/kilometer.

✅ Diagnostics and Maintenance

Modern ECUs offer built-in diagnostics that help fleet managers monitor the health of vehicles, predict failures, and minimize downtime.

Getting the ECU wrong risks compromising all of the above — and your fleet’s reputation.

Mistake 1: Overlooking Vehicle-Specific Compatibility

Perhaps the most common pitfall is assuming one ECU fits all. In reality, vehicle controllers are often custom-designed or calibrated for specific vehicles or applications.

For example, an ECU designed for a light-duty urban delivery van may not work properly in a heavy-duty electric bus or off-road construction vehicle. Battery voltage levels, motor types (AC induction vs. permanent magnet), and even vehicle weight and aerodynamics can all influence ECU requirements.

How to Avoid This Mistake:

Provide your supplier with detailed vehicle specifications.

Request compatibility confirmation in writing.

Run pilot tests with a small sample vehicle before rolling out across your fleet.

Mistake 2: Ignoring Software and Firmware Capabilities

The ECU isn’t just a piece of hardware — it’s also a software platform. Many fleet operators fail to consider whether the ECU’s firmware supports critical features like:

Customizable drive modes (eco, sport, etc.)

Integration with telematics and fleet management systems

Over-the-air (OTA) updates

Advanced diagnostic tools

Using a vehicle controller with rigid or outdated firmware can make it difficult to adapt to evolving needs, regulatory changes, or even driver feedback.

How to Avoid This Mistake:

Ask about software flexibility and update procedures.

Ensure the ECU supports standard communication protocols like CAN, LIN, or Ethernet.

Request a demonstration of the user interface and diagnostic tools.

Mistake 3: Focusing Only on Price, Not Quality

It’s natural to want to minimize costs — but selecting the cheapest vehicle electronic control unit on the market is a false economy. Low-cost ECUs may lack durability, precise calibration, or essential certifications (such as ISO 26262 for functional safety).

This can lead to premature failures, expensive repairs, and even safety violations.

How to Avoid This Mistake:

Compare total cost of ownership (TCO), not just initial price.

Verify certifications and testing reports.

Choose a reputable supplier with proven experience in your industry.

Mistake 4: Neglecting Scalability and Future-Proofing

EV technology is advancing rapidly — with new battery chemistries, charging standards, and safety regulations emerging every year. Choosing a vehicle controller that meets today’s needs but cannot accommodate tomorrow’s developments could leave your fleet obsolete.

For example, a controller limited to 400V may not support future vehicles using 800V systems for faster charging and higher efficiency.

How to Avoid This Mistake:

Select ECUs that support modular or upgradeable configurations.

Look for units that are backward- and forward-compatible with emerging standards.

Discuss your long-term plans with your supplier to align product roadmaps.

Mistake 5: Underestimating Supplier Support and After-Sales Service

Even the most advanced ECU will sometimes require support — whether it’s troubleshooting an issue, updating firmware, or training your maintenance team. Choosing a supplier that disappears after the sale can leave your fleet stranded.

How to Avoid This Mistake:

Evaluate the supplier’s technical support resources and response times.

Check customer references or reviews.

Clarify warranty terms and what’s included in after-sales service.

A good supplier is a long-term partner, not just a vendor.

Mistake 6: Failing to Consider Environmental and Operational Conditions

EVs operate in diverse and sometimes harsh environments — from freezing winters to hot, dusty construction sites. Not all ECUs are designed to withstand such conditions.

Extreme temperatures, moisture, vibrations, and electromagnetic interference can all compromise ECU performance if the unit isn’t properly rated.

How to Avoid This Mistake:

Specify environmental requirements up front (e.g., IP67 water/dust resistance, vibration resistance, wide operating temperature range).

Choose a controller that meets or exceeds the harshest conditions your fleet will encounter.

If your fleet operates internationally, ensure the ECU meets regional regulatory and environmental standards.

Conclusion

The vehicle electronic control unit is more than just another component — it’s the foundation of your EV fleet’s performance, safety, and efficiency. By carefully selecting the right vehicle controller and avoiding the common mistakes outlined above, you can ensure your fleet delivers on its promise of sustainability and reliability.

Take your time to assess compatibility, software flexibility, quality, scalability, supplier support, and environmental resilience. Working with experienced and reputable suppliers will save you time, money, and frustration in the long run.

Investing in the right ECU is not just a technical decision — it’s a strategic one that can future-proof your fleet and strengthen your competitive edge.