Everything You Need to Know About E-Axle Motor

As companies worldwide intensify their carbon reduction initiatives, many are turning to electric and hybrid vehicles. Some vehicles are entirely electric, while others incorporate electric components like an electric axle (eAxle) to reduce dependency on fossil fuels. By electrifying all or part of a vehicle’s powertrain — the system responsible for converting fuel or electricity into motion — both businesses and individuals can transition to lower-carbon transportation options. Here’s an in-depth look at e axle motors and their evolving role in the future of electric mobility.

Advancements in engineering have facilitated the electrification of various modes of transportation, allowing for a shift away from carbon-intensive vehicles. Today’s electric vehicles (EVs) boast the power and performance to rival traditional diesel-powered models, with several options tailored for performance and heavy-load applications now reaching parity with internal combustion engine vehicles.

While many businesses have successfully adopted EVs for last-mile deliveries, the integration of EVs for long-range or heavy-goods transport remains a work in progress. Despite improvements in EV infrastructure across countries like the United States, the network is not yet equipped to support large-scale electric fleets. A study projects that by 2035, truck stops designed to charge electric trucks will require as much power as a small town. Additionally, even for vehicles capable of traveling up to 500 miles on a single charge, such as Tesla’s electric semi, the cost remains a significant barrier for businesses operating on limited budgets.

For many businesses and individuals, hybrid vehicles present a more cost-effective and practical alternative. E axle motors are a crucial component in facilitating the shift to electrified transportation, powering both hybrid and fully electric systems. But what exactly are e axle motors, and how do they contribute to the broader EV landscape?

What is an eAxle?

eAxles represent a cutting-edge advancement poised to redefine how vehicles are powered. To understand their impact, let’s first explore the function of a standard axle.

A standard axle is a fundamental component of a vehicle’s powertrain, which is responsible for transmitting power from the engine or electric motor to the wheels, propelling the vehicle forward. A conventional powertrain consists of five key elements: the engine (or electric motor in EVs), transmission, driveshaft, differential, and axles. Within this system, the axle plays a crucial role in supporting the vehicle’s weight and transferring power to the wheels to ensure movement.

Traditional axles are designed to convey power and torque from the engine, allowing the vehicle to move in the desired direction. Early axles were little more than simple rods with wheels attached, but modern designs incorporate advanced mechanisms to enhance control, stability, and safety. Most vehicles have a front and rear axle, but larger or heavier vehicles may have multiple axles to support additional weight and wheels.

Over the past two decades, however, manufacturers have begun integrating axles with electric drive systems to create a more sustainable alternative – the e axle motor.

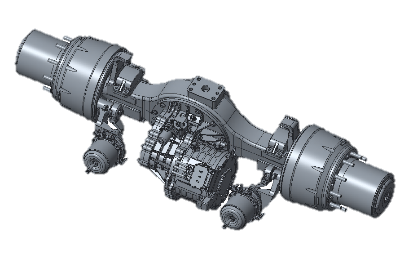

An e axle motor is a compact electric drive system that combines essential propulsion components within a traditional axle structure. Engineered to handle high motor torque and substantial brake regeneration, e axle motors, such as the adaptable Accelera models, can be customized to meet diverse vehicle applications, duty cycles, and regional specifications.

How are eAxles powered?

e axle motors draw power from battery-operated motors, which are typically powered by lithium-ion (Li-ion) batteries. While most e axle motors are equipped with a single motor, larger axles may feature two motors to provide the necessary power output. The latest generation of e axle motors integrates components like the motor and transmission into a single unit, significantly reducing weight compared to separate, standalone parts.

Which motors do eAxles use?

eAxles can be powered by various motor types, each with distinct characteristics:

- Permanent Magnet Synchronous Motor (PMS Motor): Ideal for high-performance applications, PMS motors deliver exceptional power density and efficiency.

- Induction Motor: Known for being cost-effective and durable, induction motors are relatively simple in design but have lower efficiency and power output compared to other options.

- Switched Reluctance Motor: Utilizing reluctance torque, these motors provide high motor-drive efficiency in a simple, budget-friendly design, though they typically offer lower torque capacity.

Electric powertrains (ePowertrains) can incorporate these motors in three primary configurations: integrating the motor directly into the axle, using a centralized drive system, or employing a centralized motor with a gearbox. Opting for an integrated e axle system can reduce drag, streamline the vehicle, and minimize unnecessary energy consumption.

Using fuel cells to power eAxles

Fuel cells, like batteries, provide a sustainable power source for zero-emission vehicles. In simple terms, a fuel cell consists of two electrodes — a negative anode and a positive cathode — separated by an electrolyte. In a hydrogen fuel cell, hydrogen is supplied to the anode, where a catalyst splits the molecules into protons and electrons. This process generates electricity, with water and heat as the only byproducts.

Hydrogen-powered fuel cells produce minimal or zero emissions, depending on how the hydrogen is generated. Although the infrastructure for hydrogen-powered vehicles is still under development, the technology is advancing rapidly. Experts predict that by 2030, hydrogen-powered vehicles could become widespread across roads and railways.

The benefits behind eAxle

eAxles could play a crucial role in helping businesses transition from fossil-fueled fleets to hybrid or fully electric vehicles. However, their advantages extend far beyond carbon reduction. These advanced components offer several key benefits, including:

- Enhanced Fleet Serviceability: e axle systems simplify vehicle integration by reducing the number of separate components.

- Improved Driveline Efficiency: They minimize gear losses, potentially increasing overall efficiency.

- Extended Brake Lifespan: Regenerative braking reduces brake wear and lowers maintenance needs.

- Compact Design: e axle systems consolidate components typically distributed throughout the chassis, resulting in a more compact structure.

- Optimized Battery Placement: Integrating e axle systems frees up space within the frame rails, the safest part of the chassis, for battery storage. Additional batteries can also be installed outside the frame rails, replacing conventional fuel tanks to further reduce fuel dependency.

- Lower Noise Pollution: Vehicles equipped with e axle systems operate more quietly, reducing noise emissions.

- Enhanced Driving Experience: With instant torque delivery, e axle systems provide a smoother, more responsive driving experience.

Adapting vehicles for the future

For many businesses, purchasing new vehicles is financially unfeasible. Retrofitting existing trucks with e axle systems presents a more cost-effective path to fleet sustainability. Some e axle systems and powertrain systems are designed with a modular architecture that simplifies integration. With multiple transmission options tailored for various applications, including long-range and heavy-load operations, these e axle systems help reduce fuel consumption and promote more sustainable transport solutions.

PUMBAA’s Electric E-axle Motor for Trucks

PUMBAA offers a powerful and efficient solution for electrifying heavy-duty vehicles. Designed with robust torque output and advanced thermal management, PUMBAA’s e-axle motor is engineered to handle the demanding requirements of trucks while maximizing energy efficiency. Its compact, integrated design simplifies installation and reduces overall vehicle weight, enabling improved payload capacity and extended driving range. Whether for fully electric or hybrid configurations, PUMBAA’s e-axle motor delivers reliable performance, lower maintenance costs, and a smoother, quieter ride — making it a compelling choice for fleet operators looking to transition to cleaner, more sustainable transport solutions.

Read More: Understanding EV Power Distribution Units: Essential Components, Types, and Future Trends