Where is the future development direction of permanent magnet synchronous motor?

The development of rare earth permanent magnet materials in the 1970s led to the emergence of rare earth permanent magnet motors. These motors utilize rare earth magnets for excitation, which generate a permanent magnetic field when magnetized. With superior excitation performance, they outperform conventional electrically excited motors in stability, quality, and loss reduction, thereby reshaping the traditional motor market.

In recent years, with the rapid development of modern science and technology, the performance and process of electromagnetic materials, especially rare earth electromagnetic materials have been gradually improved, coupled with the rapid development of power electronics and power transmission technology, automatic control technology, the performance of permanent magnet synchronous motor is getting better and better.

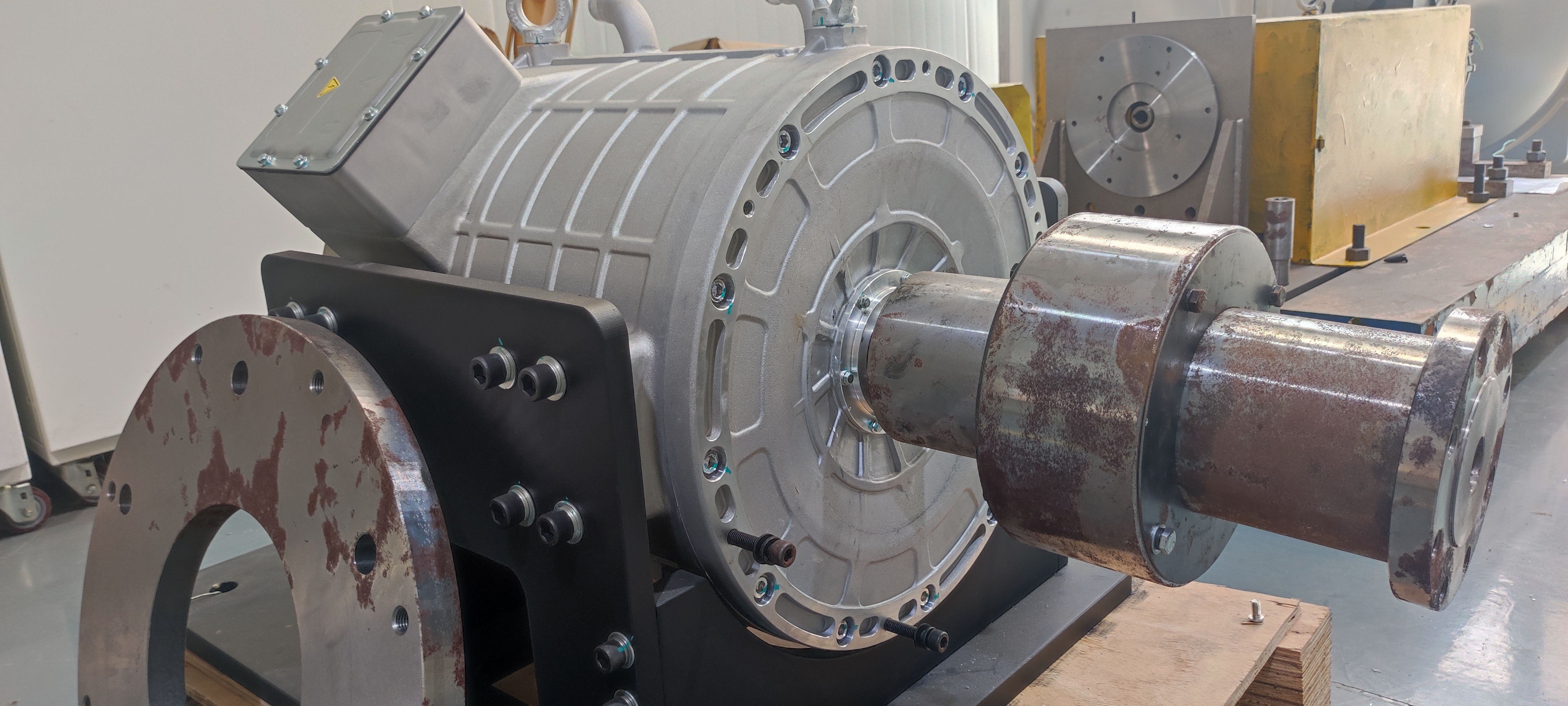

Moreover, the permanent magnet synchronous motor has the advantages of light weight, simple structure, small size, good characteristics and high power density. Many scientific research institutions and enterprises are actively carrying out the research and development of permanent magnet synchronous motor, and its application field will be further expanded.

Development and research status

1. The development basis of permanent magnet synchronous motor

① Application of high performance rare earth permanent magnet materials

Rare earth permanent magnet materials have evolved through three developmental stages: SmCo5, Sm2Co17, and Nd2Fe14B. Today, neodymium iron boron (NdFeB) magnets stand out as the most widely used type due to their superior magnetic performance. The advancement of permanent magnets has driven significant progress in permanent magnet motors. Unlike traditional electrically excited three-phase induction motors, these motors eliminate the need for electrically excited poles, simplify structural design, and eliminate rotor slip rings and brushes. This innovation enables brushless operation, reduces rotor size, enhances power density and torque density, improves energy efficiency, and allows motors to be more compact and lightweight. These advancements have expanded their application scope and accelerated the development of higher-power electric motors.

② Application of new control theory

In recent years, control algorithms have seen rapid development. Among them, vector control algorithms have fundamentally resolved the drive strategy issues for AC motors, enabling them to achieve excellent control performance. The emergence of direct torque control has simplified the control structure while demonstrating strong adaptability to parameter variations and fast dynamic torque response. Indirect torque control technology addresses the issue of significant torque pulsation at low speeds in direct torque control, thereby enhancing both motor speed and control accuracy.

③ Applications of high performance power electronics and processors

Modern power electronics serves as a vital interface between the information industry and traditional sectors, acting as a bridge between low-voltage systems and controlled high-voltage applications. The advancement of power electronics has enabled the implementation of drive control strategies. For instance, the 1970s witnessed the emergence of universal frequency converters that could transform industrial-frequency power supplies into continuously adjustable frequency power sources, thereby creating conditions for AC frequency conversion and speed regulation. These frequency converters feature soft-start capabilities after frequency setting, allowing gradual acceleration from zero to the target frequency at a predetermined rate. The acceleration rate can be continuously adjusted across a wide range, effectively resolving the startup challenges of synchronous motors.

2. Development status of permanent magnet synchronous motor at home and abroad

The first motor in history was the permanent magnet motor. At that time, the performance of permanent magnet materials was relatively poor, and the coercivity and remanence of permanent magnets were too low, so it was soon replaced by the electrically excited motor.

In the 1970s, rare-earth permanent magnet materials like neodymium iron boron (NdFeB) gained prominence due to their exceptional coercivity, remanence, strong demagnetization capability, and high magnetic energy product. These properties propelled high-power permanent magnet synchronous motors onto the historical stage. Today, research on permanent magnet synchronous motors has matured significantly, advancing toward higher speeds, greater torque, higher power output, improved efficiency, as well as miniaturization and intelligent development.

In recent years, high-end permanent magnet synchronous motors have emerged in the industry. A notable example is the 230r/min/1095kW six-phase motor developed by Germany's Siemens in 1986. When used to power naval vessels, this advanced design reduces the motor's size by nearly 60% compared to traditional DC motors while cutting energy losses by approximately 20%. Additionally, Swiss company ABB has built permanent magnet synchronous motors for ship propulsion with a maximum installed capacity of 38MW.

The research on permanent magnet motor started late in China, but with the strong investment of domestic scholars and the government, it has developed rapidly. At present, China has developed and produced 3MW high-speed permanent magnet wind generator, and CRRC Zhuzhou company is also developing more powerful permanent magnet motor.

With the development of microcomputer technology and automatic control technology, permanent magnet synchronous motors have been widely used in various fields. Now, due to social progress, people's requirements for permanent magnet synchronous motors have become more demanding, prompting the development of permanent magnet motors to have a larger speed regulation range and higher precision control.

Due to the improvement of production technology, high-performance permanent magnet materials have been further developed. This makes its cost greatly reduced and gradually applied in various fields of life.

Current technology

1. Permanent magnet synchronous motor design technology

Compared to conventional electrically excited motors, permanent magnet synchronous motors eliminate the need for excitation windings, collector rings, and excitation cabinets. This design not only significantly enhances stability and reliability but also achieves substantial efficiency improvements. In particular, built-in permanent magnet motors demonstrate advantages such as high efficiency, superior power factor, high power density per unit, strong low-voltage speed acceleration capability, and rapid dynamic response, making them ideal choices for drive applications. However, permanent magnets provide the entire excitation magnetic field, which increases cogging torque and consequently causes motor vibration and noise during operation. Excessive cogging torque can compromise both the low-speed performance of speed control systems and the high-precision positioning capabilities of position control systems. Therefore, motor design should prioritize optimizing components to minimize cogging torque.

Research indicates that common methods to reduce tooth slot torque include modifying pole arc coefficients, reducing stator slot width, implementing inclined slots and pole slot coordination, as well as adjusting magnetic pole positions, dimensions, and shapes. However, it's important to note that these measures may adversely affect other motor performance characteristics, such as potentially diminishing electromagnetic torque. Therefore, during design, engineers should strive to balance all factors to achieve optimal motor performance.

2. Permanent magnet synchronous motor simulation technology

The presence of permanent magnets in permanent magnet motors presents challenges for designers when calculating parameters such as no-load leakage permeability and pole arc coefficient. Finite element analysis software is commonly employed to optimize these motor parameters. This software enables highly accurate parameter calculations, and its application in analyzing how motor parameters affect performance yields reliable results.

Finite element computation methods provide a more convenient, efficient, and accurate approach for analyzing electromagnetic fields in motors. As a numerical method developed from the finite difference method, it has been widely adopted across scientific and engineering disciplines. The process involves mathematically discretizing continuous solution domains into discrete elements, followed by piecewise interpolation within each element to form linear interpolation functions (i.e., approximation functions). Through finite element simulation analysis, we can visually observe the magnetic flux line patterns and flux density distribution within motor interiors.

3. Permanent magnet synchronous motor control technology

Enhancing motor drive system performance is equally crucial for industrial control development. This technology optimizes system performance through its fundamental characteristics: delivering high torque during rapid acceleration and stationary acceleration under low-speed conditions, while enabling wide-range constant power speed regulation at high speeds. Table 1 provides a comparison of key motor performance metrics.

Permanent magnet motors demonstrate exceptional reliability, wide speed regulation range, and high efficiency. When paired with appropriate control methods, the entire motor system can achieve optimal performance. Therefore, selecting suitable control algorithms for efficient speed regulation enables the motor drive system to operate effectively across a broad speed range and constant power zones. Vector control methods are widely adopted in permanent magnet motor speed regulation algorithms due to their advantages including extensive speed control range, high efficiency, reliability, stability, and cost-effectiveness. These methods are extensively used in motor drives, rail transit systems, and machine tool servo applications. Different application scenarios require corresponding current vector control strategies.

Features and classifications

1. Characteristics of permanent magnet synchronous motor

Permanent magnet synchronous motors feature a simple structure, low energy loss, and high power factor. Unlike electrically excited motors that require brushes and commutators, they eliminate the need for reactive excitation currents. This design reduces stator current and resistance losses, resulting in higher efficiency, greater excitation torque, and superior control performance. However, they face challenges such as high costs and difficult starting mechanisms. With advancements in motor control technologies—particularly vector control systems—permanent magnet synchronous motors now enable wide-range speed regulation, rapid dynamic response, and high-precision positioning control. These capabilities are driving increased research efforts across various fields.

2. Classification of permanent magnet synchronous motors

① According to the different division of rotor magnetic field waveform formation

Due to the different shapes of the rotor magnets in permanent magnet synchronous motors, the waveforms formed by the spatial distribution of the rotor's magnetic field also vary. Conventionally, they are divided into two types: sinusoidal permanent magnet synchronous motor speed control systems (where the rotor generates a sinusoidal back electromotive force on the stator) and brushless DC motors (BLDCM), where the rotor produces a trapezoidal back electromotive force on the stator.

② According to the different spatial structure of permanent magnets in the rotor

Permanent magnet synchronous motors are classified into surface-mounted and built-in types based on the spatial arrangement of permanent magnets in the rotor. Surface-mounted models feature tile-shaped magnets that adhere tightly to the outer surface of the rotor core. A key characteristic of these motors is that the inductance values for both direct-axis and alternating-axis configurations remain identical.

In built-in permanent magnet motors, the permanent magnets are housed within the rotor core. Between the outer surface of these magnets and the inner circumference of the stator core, there are pole shoes made of ferromagnetic material. These pole shoes serve to concentrate magnetic flux, thereby enhancing air-gap magnetic density and improving the waveform of the no-load air-gap magnetic field. A key feature of this type of permanent magnet motor is its asymmetric configuration between the direct-axis and alternating-axis magnetic circuits.

The performance of these two motors is different. Compared with the surface permanent magnet motor, the built-in permanent magnet motor has the advantages of weak magnetic speed expansion ability, fast dynamic response and small cogging torque.

Development trend of permanent magnet synchronous motor

1.Permanent magnet brushless DC motor (BLDCM)

Since the 1980s, control technologies—particularly control theory strategies—have seen rapid development. Advanced approaches like sliding mode control and variable structure control are now being integrated into controllers for permanent magnet brushless motors. This advancement has paved the way for high-performance systems to evolve into intelligent, flexible, and fully digitalized solutions. As living standards continue to rise and environmental protection awareness grows, the adoption of high-performance motor systems has become an inevitable trend in the motor industry. These systems are also expected to see broader applications in small motor sectors such as electric vehicles and household appliances in the coming years.

2. Development trend of PMSM

PMSM servo system will develop in two directions due to its own technology and application field:

① Simple and low-cost servo systems in the fields of office automation equipment, simple CNC machine tools, computer peripheral equipment, household appliances and industrial motion control with low performance requirements;

② High-precision CNC machine tools, robots, precision feed drive for special processing equipment, as well as high-performance fully digital, intelligent and flexible servo systems for aviation and aerospace. The latter can better reflect the advantages of servo systems and will be the main direction of future development.

Classification of design methods for permanent magnet synchronous motors

1.Magnetic circuit method:

The non-uniform alternating magnetic field in a motor can be equivalently modeled as a corresponding magnetic circuit, transforming magnetic field calculations into magnetic circuit computations. However, since the equivalent magnetic circuit calculation employs numerous correction coefficients, its exact values cannot be theoretically determined. Therefore, empirical data is typically used. If the preliminary design fails to meet requirements, designers must recalibrate the correction values and recalculate the results.

2. Finite element method:

To ensure accurate calculations, electromagnetic field analysis is essential, including factors like permanent magnet pole configuration and local demagnetization. Utilizing finite element analysis software for numerical computation has significantly reduced product development costs while providing precise data for motor optimization. Advancements in computing power have enabled the evolution of various analytical methods in electromagnetic field numerical computation. The finite element method essentially transforms problems into structurally solvable systems, idealizing continuous systems with infinite degrees of freedom into finite sets of unit cells. Currently, ANSYS stands as the most widely used finite element simulation software, capable of conducting comprehensive joint simulations for entire motor systems.

3. Field road combination method:

While the magnetic circuit method offers rapid computation speed, it lacks precision. Although computer-based methods provide high accuracy, they are computationally intensive and require advanced hardware. By integrating finite element analysis with traditional magnetic circuit techniques in electromagnetic motor numerical calculations, we can enhance both computational efficiency and accuracy—a practical approach with significant value for motor parameter design. The field-circuit integration methodology follows a three-step process: First, geometric models are preliminarily established using magnetic circuit calculations. Subsequently, finite element analysis is applied to accurately determine the coefficients requiring correction in the equivalent magnetic circuit method.