Why Automotive Electric Motors Are the Heart of EV Revolution

Since the birth of the first mass-produced electric car in 1884, electric vehicles (EVs) have walked a long and winding road. After a brief period of glory in the early 20th century, EVs were pushed aside by internal combustion engine (ICE) vehicles due to their limited driving range, battery life issues, and inconvenient charging. For decades, gasoline-powered cars dominated the roads, setting the standard for speed, convenience, and affordability.

But by the late 20th century, the downsides of ICE cars had become impossible to ignore. Rapid growth in private car ownership meant more air pollution, more greenhouse gas emissions, and deeper dependence on fossil fuels. Governments and automakers worldwide began to revisit the technology once considered obsolete. Then came 2012, when Tesla released the Model S. With its luxury positioning, impressive range, and sleek performance, the Model S not only captured media attention but also changed consumer perception. Suddenly, EVs were no longer seen as quirky experiments—they became aspirational products with real-world advantages.

From that point on, the EV revolution accelerated, with governments introducing subsidies, automakers investing heavily in R&D, and consumers beginning to view EVs as practical alternatives. Yet beneath the headlines about batteries, charging networks, and policy incentives, lies the true beating heart of this transformation: the automotive electric motor.

The Basics of Automotive Electric Motors

At its core, an electric motor is a device that converts electrical energy into mechanical energy. Unlike internal combustion engines, which rely on the burning of fossil fuels to create motion, electric motors operate through electromagnetic fields. This fundamental difference explains why EVs can achieve far higher efficiency than conventional cars. While ICE vehicles typically convert only about 20–30% of the energy in fuel into actual motion, EV motors can achieve efficiencies of over 85–90%.

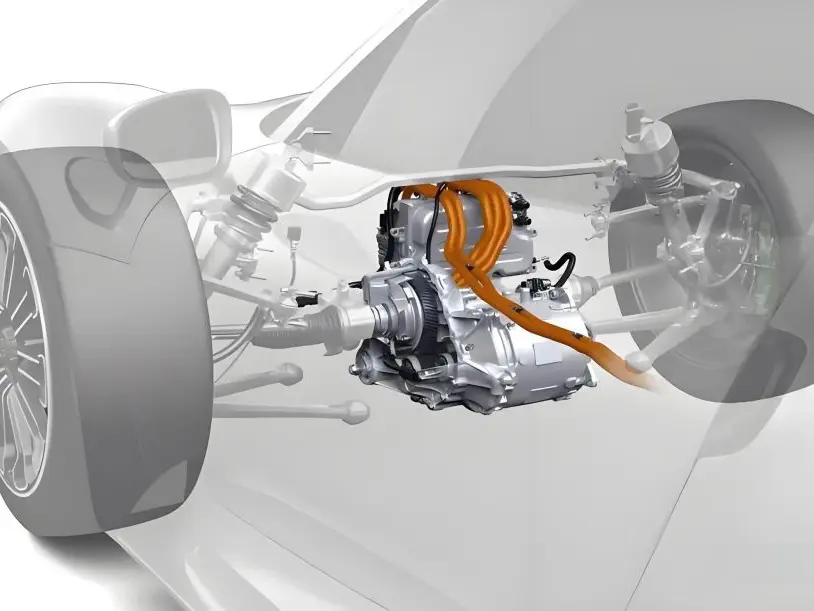

Another defining feature of electric motors is their simplicity. With fewer moving parts, they require less maintenance, operate quietly, and generate minimal vibrations. This not only improves driving comfort but also reduces long-term ownership costs. In addition, the modular nature of motors allows for multiple configurations—from single-motor rear-wheel drive systems to dual-motor all-wheel drive setups, and even wheel-hub motors that eliminate the need for axles.

Types of Automotive Electric Motors

Not all motors are created equal. Automakers use different motor types depending on cost, performance, and efficiency requirements. The four most common are:

DC Brushed Motors – Among the oldest types, they are simple and cheap but suffer from high maintenance needs due to brush wear.

Brushless DC Motors (BLDC) – Widely used today, BLDC motors are efficient, reliable, and lightweight, making them ideal for modern EVs.

Induction Motors (AC Motors) – Popularized by Tesla in its earlier models, induction motors are robust, relatively inexpensive, and perform well under variable loads.

Permanent Magnet Synchronous Motors (PMSM) – Increasingly common, PMSMs are highly efficient and deliver strong torque at low speeds, though they rely on rare earth materials.

Here is a comparison to illustrate their differences:

|

MotorType |

Efficiency |

Cost |

Maintenance |

TorqueDelivery |

CommonUsage |

|

DC Brushed |

Moderate |

Low |

High |

Moderate |

Early EVs, budget scooters |

|

BLDC |

High |

Medium |

Low |

Strong |

Mainstream EVs, e-bikes |

|

Induction |

High |

Medium |

Low |

Smooth, flexible |

Tesla (early models), industrial use |

|

PMSM |

Very High |

High |

Low |

Excellent |

Premium EVs, hybrids |

This variety allows manufacturers to choose the best motor depending on whether they prioritize affordability, efficiency, or high performance.

How Automotive Electric Motors Power EVs

The fundamental role of the electric motor is to convert electricity stored in the battery into motion. Unlike ICEs, which must operate within a narrow range of revolutions per minute (RPM) to achieve peak performance, electric motors can deliver maximum torque from zero RPM. This means that the instant a driver presses the accelerator, the car responds immediately with powerful acceleration.

This characteristic explains why EVs like Tesla’s Model S P85D stunned the world with a 0–100 km/h acceleration time of just 3.1 seconds. Despite weighing as much as a large SUV and carrying up to seven passengers, it outperformed even luxury sports sedans costing several times more. By removing the need for complex transmissions, clutches, and gears, electric motors not only simplify the drivetrain but also unlock unique performance capabilities.

Efficiency and Performance Benefits

One of the strongest selling points of EVs lies in their efficiency. Traditional vehicles waste most of their energy as heat, but EVs use electricity more effectively. Combined with regenerative braking—where motors act as generators to recover energy during deceleration—EVs further minimize waste.

Electric motors also allow flexible design choices. Dual-motor setups make all-wheel drive cheaper and more efficient. Motors placed directly on the wheels open possibilities for precise torque vectoring, where each wheel’s power is independently controlled for superior handling and stability. The result is a smoother, faster, and safer driving experience.

From a cost perspective, while batteries remain expensive, the motors themselves are relatively cheap. This economic advantage is why even entry-level EVs often deliver superior acceleration compared to their ICE counterparts.

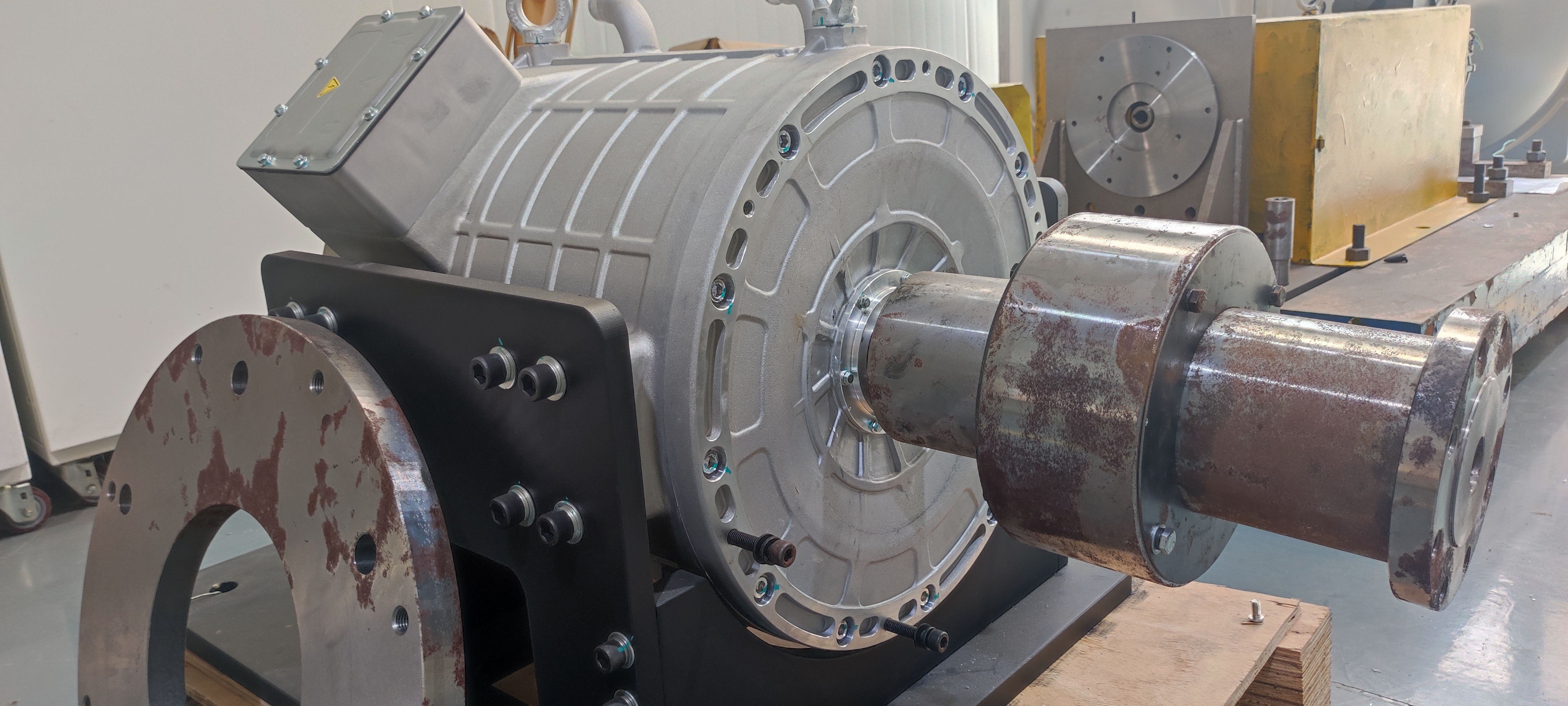

Technological Innovations in Automotive Electric Motors

Innovation continues to reshape the motor landscape. Advances in cooling systems, lightweight materials, and power electronics are pushing performance boundaries. One promising trend is the move toward axial flux motors, which are lighter and smaller than traditional radial flux motors while offering higher torque density. Companies like YASA (acquired by Mercedes-Benz) are already commercializing this technology for next-generation EVs.

In addition, research into reducing reliance on rare earth magnets is gaining momentum. With supply chain risks and environmental concerns surrounding rare earth mining, new designs seek to achieve similar performance without costly materials. Similarly, silicon carbide inverters are enabling motors to operate more efficiently, with less heat loss and better power handling.

Automotive Electric Motors and EV Range

A key concern for consumers remains EV range. While batteries are the primary determinant, motor efficiency plays a crucial role. High-efficiency motors minimize energy waste, directly extending driving distance per charge. For example, PMSMs are often favored in long-range EVs because of their superior efficiency, whereas induction motors, while durable, consume slightly more energy.

Different strategies also exist to optimize range. Some vehicles use dual-motor systems where one motor handles high-demand scenarios, and the other operates efficiently during cruising. By intelligently switching between them, the vehicle balances performance with conservation.

Challenges in Automotive Electric Motor Development

Despite their advantages, motors are not without challenges. Manufacturers must balance efficiency, cost, weight, and sustainability. Permanent magnet motors rely on rare earth elements, which are expensive and geopolitically sensitive. Induction motors, while cheaper, may not deliver the same efficiency at highway speeds.

Cooling is another challenge. As motors operate at high power outputs, heat buildup can reduce efficiency and shorten lifespan. Innovative cooling techniques—such as oil immersion or integrated cooling jackets—are being developed to address this.

Finally, integration with batteries and power electronics requires careful engineering. Motors are only as effective as the systems that support them, and the interplay between motor design, inverter efficiency, and battery chemistry remains a complex engineering puzzle.

The Future of Automotive Electric Motors in the EV Revolution

Looking ahead, electric motors will only grow more central to the EV revolution. As battery costs fall and charging networks expand, motors will increasingly define the driving experience. Future vehicles may feature in-wheel hub motors for ultimate precision, lightweight composite materials for better efficiency, and AI-driven software to optimize torque distribution in real time.

At the same time, the rise of specialized EV categories—such as neighborhood electric vehicles in the U.S. or low-speed electric cars in rural China—shows how flexible motors can be adapted to vastly different market needs. From ultra-fast luxury sedans to low-cost community shuttles, electric motors are proving that they are not just functional components but enablers of entirely new mobility models.

Conclusion

The journey of the electric vehicle has been long, from its early promise in the 19th century, through decades of obscurity, to its resurgence in the 21st century. But what makes EVs truly revolutionary is not only the batteries or the charging infrastructure—it is the electric motor.

Electric motors transform how vehicles move, making them cleaner, faster, and more efficient. They open up new design possibilities, reduce reliance on fossil fuels, and redefine performance benchmarks. Challenges remain, including costs, raw material constraints, and thermal management, but innovation is relentless.

As governments continue to support clean mobility and consumers increasingly demand sustainable yet powerful vehicles, the role of electric motors will only grow. They are not just the heart of EVs—they are the pulse of the automotive revolution itself.