Why Use Flat Wire Motor Winding in EV Motors?

When people talk about electric vehicles, the conversation usually revolves around battery range or charging speed.

But what really drives an EV’s performance isn’t just the battery—it’s the motor. And inside that motor, a quiet revolution is taking place.

The shift from traditional round wire windings to flat wire designs is reshaping what EVs can do, and the implications go far beyond what meets the eye.

Let’s break it down—without the technical jargon.

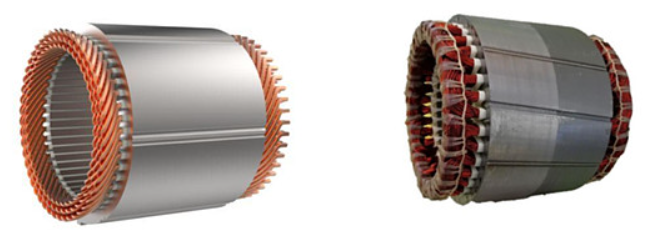

More Than Just a Shape: It’s a Space Revolution

Imagine trying to fill a suitcase with round oranges. No matter how neatly you pack them, gaps will remain.

Now imagine stacking rectangular chocolate bars—they fit snugly, with almost no wasted space. That’s the fundamental difference between round and flat wire windings.

Flat wires allow manufacturers like us at Pumbae to achieve what engineers call a “high slot fill factor.”In simple terms?

We pack more copper into the motor. More copper means more conductive material, which translates into higher power density. That’s why a motor built with flat wire windings can deliver greater torque and efficiency, often in a smaller and lighter package. For EV makers, this opens up new possibilities—whether it’s improving acceleration, extending range, or freeing up space for other components.

The Hidden Perk: Stiffness and Cooling

But there’s more to flat wire windings than just efficient packing. The shape itself brings mechanical advantages. A flat wire is stiffer, more robust. When you’re dealing with high rotational speeds and intense electromagnetic forces, that stiffness matters. It reduces vibrations and noise, leading to a quieter, smoother ride—a subtle but noticeable refinement drivers appreciate.

Then there’s cooling. EVs demand a lot from their motors, especially under heavy loads. Round wires, with their curved surfaces, only make point contact with each other, trapping heat. Flat wires, by contrast, align closely, creating broad pathways for heat to escape. This improved thermal performance means the motor can sustain high power output for longer periods without overheating. Whether you’re climbing a steep hill or pushing the vehicle on a track, that thermal resilience makes all the difference.

Manufacturing: Where the Magic Really Happens

Building a flat wire motor isn’t easy. The process—shaping rigid copper into precise hairpin forms, inserting them into the stator, and laser-welding the ends—requires advanced equipment and expertise. Many manufacturers stick with round wires simply because they’re easier to handle.

At Pumbaaev, we see this complexity as an opportunity. We’ve embraced automated production lines specifically designed for flat wire motor assembly.

For us, overcoming these manufacturing challenges isn’t just part of the job—it’s what sets our components apart. It’s where precision engineering meets real-world performance, and it’s why more EV manufacturers are turning to specialized partners like us.

Real-World Impact: What This Means for Your EV

You might not see the motor when you look at an electric vehicle, but you’ll feel its influence every time you drive.

A flat wire motor doesn’t just improve efficiency on a spec sheet—it changes the driving experience.

Quicker acceleration, quieter operation, and consistent performance even under stress are all tangible benefits. And because these motors are more durable, they also contribute to the long-term reliability of the vehicle.

This isn’t just an incremental step forward. It’s a fundamental upgrade—one that aligns with the broader shift in the automotive industry toward smarter, more sophisticated electric drivetrains.

Looking Ahead

As electric vehicles continue to evolve, components like motors will play an increasingly central role.

At Pumbaaev, we’re committed to staying at the forefront of this evolution—not just by keeping up with trends, but by setting them. From design to manufacturing, we focus on delivering solutions that balance performance, durability, and efficiency.

Ready to explore how advanced motor technologies can elevate your electric vehicle projects? Learn more about our manufacturing expertise and product offerings at www.pumbaaev.com.