Beyond Torque and Speed: The Real Battleground in Motor Design

When discussing electric motors, we often focus first on peak power and torque. But the real engineering challenges lie in the details: How to maintain efficiency under high loads? How to reduce size without sacrificing lifespan? How to achieve both fast and reliable production? The answers often lie not in magnets or control algorithms, but in the most fundamental aspect—how copper wires are placed inside the stator.

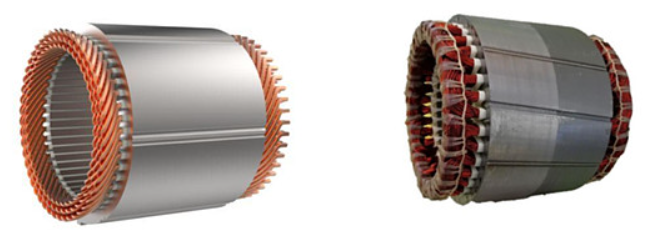

Traditional random winding methods, with their flexibility and low barrier to entry, have dominated for decades. However, in today's pursuit of ultimate performance, their inherent randomness, low slot fill factor, and thermal bottlenecks have become impossible to ignore. It's time to re-examine the motor's "circulatory system." This brings us to today's protagonist—the hairpin motor. It feels less like an evolution and more like a "structural redesign" of the motor's heart.

Deep Dive into Hairpin Windings: How Geometry Redefines Performance

Going beyond the basic advantage of simply "packing more copper," let's explore the geometric benefits of hairpin motors:

-

Combating the Skin Effect: At high frequencies (high RPM), alternating current tends to crowd towards the conductor's surface (the skin effect), increasing resistance. The flat shape of the hairpin motor's windings, compared to round wires of the same cross-sectional area, provides a larger effective perimeter, significantly reducing AC losses at high frequencies. This is key to achieving high efficiency in high-speed motors.

-

Managing the Proximity Effect: This refers to losses caused by magnetic field interactions between adjacent conductors. Hairpin motors, through precise positioning and compact arrangement, allow for better management and prediction of these losses. The unpredictable nature of random winding makes this optimization difficult.

-

Mechanical Rigidity and NVH: Once formed, the hairpin winding acts like a structural component, greatly enhancing the stator's rigidity. This not only improves heat dissipation (thanks to superior thermal conduction paths) but also effectively suppresses vibrations caused by electromagnetic forces, directly contributing to reduced Noise, Vibration, and Harshness (NVH).

The Art of Challenge and Trade-Offs in Hairpin Windings

-

The "Art of Bending" End Windings: The ends of the hairpins require precise bending and welding. This geometric design is a discipline in itself, requiring a balance between electromagnetic performance (shorter ends reduce resistance), manufacturability (feasibility of bending), and insulation reliability.

-

Challenges of the Insulation System: The wide surface contact between flat wires places extremely high demands on the thickness, uniformity, and voltage withstand capability of the insulation enamel. Any flaw can lead to inter-turn short circuits. This drives the adoption of more advanced insulation materials, such as ceramic-filled enamels.

-

Material Cost and Lightweighting Pressure: We acknowledge the cost and weight pressures associated with using more copper. The industry is exploring solutions like using higher-grade copper alloys (increasing strength to allow for thinner insulation) or hollow conductors (serving both conduction and coolant flow purposes).

Evolution of Applications: From Luxury EVs to Ubiquitous High-Efficiency Power

-

Pioneering Field (Electric Vehicles): Hairpin motors are now used not only in main traction motors but are also expanding into brake systems, air conditioning compressors, and other auxiliary motors, pursuing system-level efficiency gains.

-

Core Field (Industrial Power): In scenarios demanding high reliability and low downtime, such as data center pumps, large HVAC compressors, and servo motors, the longevity and energy efficiency benefits brought by hairpin motors far outweigh their initial cost.

-

New Frontiers: Exploring application potential and unresolved challenges in aerospace (extreme power density), renewable energy (large wind turbines), and even concepts like superconducting hairpin windings. The trend is clear: hairpin technology is shifting from a "high-end option" to a "mainstream high-performance solution."

How Automated Production Lines Turn Blueprints into Reality

-

Precision Insertion: This is not simple "insertion." It involves machine vision guiding robotic arms, managing tolerances, and protecting the insulation layer during the pin insertion process.

-

End Forming: The precision of the bending dies determines the consistency of the end-winding shape and the stability of electromagnetic performance. This is a precise "plastic processing" operation.

-

Laser Welding: A deep comparison shows laser welding's advantages over traditional TIG welding: smaller heat-affected zone, less deformation, and exceptional consistency. In-process quality monitoring (like real-time penetration depth monitoring) ensures the reliability of every weld point.

-

Online Testing: How the production line integrates armature testers to perform 100% testing for resistance, insulation withstand voltage, and inter-turn shorts immediately after welding, achieving "zero-defect" output.

Core Argument: The performance and quality of a hairpin motor are essentially "designed in software, solidified in the tooling, and realized on the automated production line." Without top-tier manufacturing processes, even the best design remains theoretical.

At Pumbaaev: Turning Promise into Reality

At Pumbaaev, we understand this deep interdependence. Our new automated production line was built specifically to deliver on the technical promise of hairpin windings.

Concrete Advantages: "Our production line is equipped with laser welding systems and precision servo presses, ensuring micron-level accuracy in every step from insertion to forming. This directly translates into quantifiable advantages in the efficiency and power density of our motor products.

For our customers, this means they don't need to worry about mass production consistency or reliability risks. They receive hairpin motors performing at their full potential, ready for direct integration into their next-generation products, accelerating their time to market."

Riding the Technological Wave, Co-creating the Power Future

The hairpin motor is more than just a manufacturing process; it represents a shift in motor design philosophy from "adequate" to "optimal." It demands closer collaboration between engineers, materials scientists, and manufacturers.

With the application of AI in production line quality control and the development of new materials (like carbon nanotube-enhanced conductors), the next evolution of hairpin windings is something to look forward to. We stand at the dawn of a new era.

When your product performance hits a ceiling, the problem might lie hidden in the details of the windings. Partnering with a deep-manufacturing expert like Pumbaaev means you gain end-to-end technical empowerment, from material selection and electromagnetic design to scalable manufacturing.

Let's discuss how truly advanced hairpin motor technology can inject a decisive advantage into your project. Explore our technical capabilities and case studies at: www.pumbaaev.com