The parts of an electric vehicle You Need to Know

Understanding the parts of an electric vehicle is essential for anyone interested in EV technology. Every component, from the battery pack to the traction motor and power electronics, works in unison to create a smooth, emission-free driving experience. Unlike traditional vehicles, which rely on internal combustion engines, EVs integrate electrical systems that maximize efficiency, reduce maintenance, and improve overall performance. In this article, we explore the essential parts of an electric vehicle and explain how each contributes to the future of mobility.

1. The Power Source Unveiling the Electric Vehicle Battery Pack

At the heart of the parts of an electric vehicle is the battery pack, which stores and supplies electrical energy. Most EVs today use lithium-ion batteries for their high energy density, long life cycles, and safety. Battery packs consist of modules and thousands of individual cells, monitored by a Battery Management System (BMS) that ensures balanced voltage, temperature control, and optimal performance.

Battery size and configuration vary depending on vehicle type:

- Passenger EVs often use 40–100 kWh packs, providing ranges of 200–400 miles.

- Commercial EVs, including trucks and buses, may employ 300+ kWh packs to handle heavy loads over long distances.

The battery pack also contributes to vehicle stability, forming part of the chassis and lowering the center of gravity. Thermal management—using liquid cooling, air channels, or phase-change materials—is critical to prevent degradation and ensure safety.

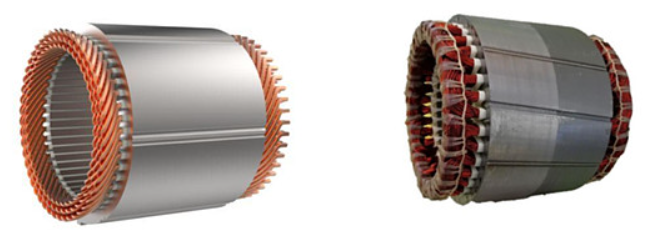

2. The Motor Mind Understanding the Electric Traction Motor

The electric traction motor converts stored battery energy into mechanical power. Commonly, EVs use Permanent Magnet Synchronous Motors (PMSM) or Induction Motors:

- PMSM motors are compact, efficient, and provide instant torque at low speeds, perfect for city driving.

- Induction Motors, known for robustness, reduce reliance on rare-earth materials while offering high-speed durability.

Unlike internal combustion engines, which reach peak torque at higher RPMs, EV motors deliver maximum torque instantly, enabling rapid acceleration. Modern traction motors, paired with Motor Controller Units (MCU), also facilitate regenerative braking, recovering energy during deceleration.

3. The Power Boss How the Power Electronics Controller Operates

Power electronics manage electricity between the battery and motor. The controller adjusts current, voltage, and torque in real time to optimize efficiency. Advanced controllers can integrate regenerative braking, ensuring energy is recovered instead of lost as heat.

Controllers also communicate with the Vehicle Control Unit (VCU), coordinating speed, stability, and safety functions. For high-performance EVs, sophisticated algorithms balance torque delivery, reducing energy loss while maximizing acceleration.

4. Charging Your EV The Onboard Charger and Port Essentials

The onboard charger converts AC from the grid into DC for the battery. Coupled with the charging port, it provides a safe and reliable interface for home or public charging. Fast-charging technologies, like DC fast chargers, can replenish 80% of battery capacity in under 30 minutes, improving usability for long trips.

5. The Voltage Shift The Role of the DC-DC Converter

EVs operate on high-voltage battery systems, while many components (lights, sensors, infotainment) require low voltage. The DC-DC converter steps down voltage, powering auxiliary systems safely and efficiently. Reliable converters prevent voltage spikes and improve overall electrical system stability.

6. Thermal Management Systems Keeping an EV at the Perfect Temperature

Efficient temperature control ensures battery longevity, motor performance, and passenger comfort. Systems may include:

- Liquid cooling for batteries and motors

- Air cooling for lightweight or smaller EVs

- Phase-change materials for thermal buffering

Proper thermal management prevents overheating, which can degrade components and reduce driving range.

7. The Transmission of Power The Single-Speed Gearbox in EVs

Most EVs use a single-speed gearbox because electric motors deliver consistent torque across a wide speed range. This simplifies drivetrain design, reduces maintenance, and improves energy efficiency compared to multi-speed transmissions in combustion-engine vehicles.

8. Giving Power Back How Regenerative Braking Systems Work

Regenerative braking converts kinetic energy into electrical energy during deceleration. Instead of losing energy as heat, the motor acts as a generator, recharging the battery. This system enhances efficiency, reduces brake wear, and extends driving range, particularly in stop-and-go city traffic.

9. The Structural Backbone The EV Platform and Skid Plate

The EV platform integrates all major components into a unified structure. A skid plate protects the battery and electronics from road debris and accidents. The platform also improves rigidity, lowering vibration and noise for a more comfortable ride.

10. The High-Voltage Network Cables and Connectors

EVs rely on a high-voltage network to transmit power safely between the battery, motor, and controllers. Advanced insulation, secure connectors, and safety cut-offs prevent accidental shock and ensure consistent power delivery. Proper design also minimizes energy losses during transmission.

Conclusion

The parts of an electric vehicle—battery pack, traction motor, controllers, chargers, thermal systems, gearbox, regenerative braking, platform, and high-voltage network—work together to deliver a highly efficient, low-maintenance, and eco-friendly driving experience. As EV technology advances, these components continue to evolve, making electric vehicles not only a sustainable choice but also a superior alternative to traditional internal combustion vehicles.