The Role of Electric Car Power Inverters in Enhancing Electric Vehicle Performance

Introduction

As the global automotive landscape transitions rapidly toward electrification, electric vehicles (EVs) have emerged as the front-runners in sustainable transportation. Amid growing environmental concerns, increasing fuel prices, and advances in battery technology, EVs offer a cleaner, more efficient alternative to internal combustion engine (ICE) vehicles. Yet, the performance and reliability of EVs depend not just on the battery or the electric motor, but also on the sophisticated electronics that manage energy flow — one of which is the electric car power inverter.

The power inverter in electric vehicles plays a pivotal role in energy conversion and motor control. Often overlooked by casual users, this component ensures that energy stored in the battery is delivered in the right form, at the right time, and in the right amount. This blog will delve into what an electric car power inverter is, how it functions, and its significance in enhancing EV performance.

What is a Power Inverter in Electric Vehicles?

A power inverter in electric vehicles is a key electronic device that converts direct current (DC) from the EV's battery into alternating current (AC) required by the electric motor. Since most EVs use AC motors due to their efficiency and regenerative capabilities, the inverter acts as a translator between the battery and the motor.

Inverters also manage the reverse process during regenerative braking — converting AC generated by the motor back into DC to recharge the battery. Thus, they serve dual functions: powering the motor and assisting in energy recovery.

These inverters are engineered using advanced semiconductor materials and control algorithms to ensure fast switching, minimal energy loss, and precise control. In essence, without a functioning electric car power inverter, the vehicle's motor cannot operate, making this device indispensable.

How the Electric Car Power Inverter Works

Understanding the functionality of the electric car power inverter involves examining its main roles:

1 DC to AC Conversion

The primary task of the inverter is converting the DC voltage from the battery into AC voltage that the electric motor can use. This conversion is achieved using semiconductor switches such as IGBTs (Insulated Gate Bipolar Transistors) or MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors). These switches turn on and off rapidly to simulate an AC waveform.

2 Frequency and Voltage Control

By adjusting the frequency of the AC output, the inverter controls the speed of the electric motor. Similarly, voltage control determines the motor's torque. This capability allows the inverter to manage acceleration, cruising, and deceleration seamlessly.

3 Regenerative Braking

During braking, the motor acts as a generator, producing AC power. The inverter converts this AC back into DC, which is then stored in the battery. This regenerative process improves energy efficiency and extends the vehicle's range.

4 Real-time Feedback and Control

Modern inverters come with integrated control units that gather real-time data on speed, torque demand, battery state, and more. This data is used to continuously adjust power delivery for optimum performance and safety.

Importance of Power Inverter in Electric Vehicle Performance

The power inverter in electric vehicles significantly influences multiple aspects of vehicle performance:

1 Acceleration and Torque Delivery

By precisely managing voltage and frequency, the inverter ensures smooth and responsive acceleration. Whether you're cruising down a highway or climbing a steep incline, the inverter delivers the necessary power in real-time.

2 Range Optimization

Efficient power conversion means less energy is lost as heat, allowing more stored battery energy to be utilized for driving. This directly translates to better range — a critical factor for EV users.

3 Energy Recuperation

Inverters enable regenerative braking, allowing energy that would otherwise be lost as heat to be stored and reused. This function alone can increase range by up to 10-15%.

4 Customizable Driving Modes

Advanced inverters support various driving modes such as eco, sport, and comfort. These modes alter power delivery patterns, enhancing user experience and adaptability to different driving conditions.

Electric Car Power Inverter and Battery Interaction

The electric car power inverter and the battery work in close coordination to ensure vehicle efficiency and longevity:

Voltage Compatibility

The inverter is designed to match the battery's voltage range, adjusting the AC output accordingly. This alignment is crucial for maintaining stable motor operations and preventing electrical stress.

Battery Management System (BMS) Integration

Inverters work with the BMS to monitor current draw, voltage levels, and thermal conditions. This cooperation prevents overcharging, deep discharging, and overheating — all of which can degrade battery health.

Intelligent Power Distribution

During peak load scenarios like acceleration or hill climbing, the inverter dynamically adjusts power output to balance performance and energy efficiency.

Enhanced Regenerative Efficiency

A sophisticated inverter maximizes regenerative energy capture by fine-tuning motor resistance during deceleration, feeding more energy back into the battery.

Innovations in Electric Car Power Inverter Technology

Technological advances are continuously redefining the capabilities of electric car power inverters:

Silicon Carbide (SiC) Semiconductors

SiC materials offer lower switching losses and can operate at higher temperatures compared to traditional silicon. SiC inverters are more compact, lighter, and more efficient.

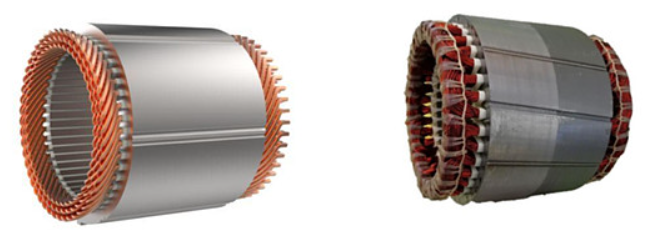

Integrated Motor-Inverter Units

Automakers are developing integrated modules that combine the motor, inverter, and control electronics into a single compact unit. This integration reduces weight, cost, and space requirements.

Machine Learning and AI Algorithms

Smart inverters are using AI to predict driving patterns and environmental conditions, enabling more efficient energy usage and real-time performance tuning.

Wireless Control Interfaces

Next-generation inverters are incorporating wireless communication with vehicle systems, reducing wiring complexity and improving system diagnostics.

Bidirectional Inverters

These allow for vehicle-to-grid (V2G), vehicle-to-home (V2H), and vehicle-to-load (V2L) functionality, turning the car into a mobile energy source.

Power Inverter in Electric Vehicle Efficiency and Range

The efficiency of the power inverter in electric vehicles plays a decisive role in determining vehicle range and overall performance:

Conversion Efficiency

Modern inverters achieve over 95% conversion efficiency, minimizing energy waste and maximizing available power.

Lightweight Design

Advanced materials and compact designs reduce inverter weight, contributing to better vehicle efficiency and extended range.

Intelligent Energy Use

Adaptive load handling ensures that energy consumption is matched precisely to driving needs, whether it’s slow traffic or high-speed travel.

Reduced Cooling Requirements

Efficient inverters produce less heat, which means smaller cooling systems, lower auxiliary power consumption, and improved overall energy economy.

Thermal and Safety Considerations

Given the high power levels involved, electric car power inverters must adhere to strict thermal and safety standards:

1 Thermal Management

- Use of liquid or air cooling systems.

- Heat sinks and thermal pads for efficient heat dissipation.

- SiC-based components that operate at higher temperatures with less heat generation.

2 Safety Features

- Overcurrent Protection: Prevents damage during electrical surges.

- Overtemperature Shutdown: Automatically powers down the inverter when it overheats.

- Short Circuit Protection: Detects and isolates faults instantly.

- Insulation Monitoring: Ensures electrical isolation is intact.

These features are critical to ensure not only the longevity of the inverter but also the overall safety of the vehicle.

Maintenance and Diagnostics of Electric Car Power Inverters

Proper maintenance and early diagnostics are essential to ensure the long-term functionality of the electric car power inverter:

1 Routine Maintenance

- Inspect cooling systems and clean air passages.

- Check electrical connections for corrosion or damage.

- Monitor inverter logs for unusual readings.

2 Diagnostic Tools

- Onboard diagnostics (OBD-II) systems provide fault codes and performance data.

- OEM diagnostic tools offer in-depth analysis and firmware updates.

- Predictive maintenance tools use sensor data and AI to forecast potential failures.

3 User Education

EV owners should understand basic inverter maintenance to recognize early warning signs such as abnormal noise, decreased performance, or dashboard alerts.

Future of Power Inverter in Electric Vehicles

The future of power inverters in electric vehicles is shaped by technological convergence and evolving consumer demands:

1 800V Architectures

Emerging EVs are adopting 800V systems for faster charging and higher efficiency, requiring advanced inverter designs capable of handling higher voltages safely.

2 Integration with Autonomous Driving

Inverters will increasingly interact with AI-driven systems to optimize power flow based on real-time traffic and route data.

3 Enhanced V2X Capabilities

Power inverters will support broader V2X (Vehicle-to-Everything) functions, integrating vehicles into smart homes and energy grids.

4 Modular, Scalable Platforms

Automotive manufacturers will benefit from modular inverter designs that can be adapted across different EV models, reducing R&D costs and production timelines.

5 Advanced Software Control

Future inverters will rely more on software-defined control systems, allowing for remote updates, diagnostics, and customization.

Conclusion

In summary, the electric car power inverter is a cornerstone of EV functionality, directly influencing energy efficiency, performance, range, and safety. As EV adoption accelerates, so too does the innovation surrounding inverter technology — from SiC semiconductors and AI control to V2G capabilities and modular integration.

Understanding the central role of the power inverter in electric vehicles not only highlights its engineering significance but also empowers consumers and developers to appreciate the advanced technologies making EVs a practical and sustainable mobility solution.

With ongoing advancements, the future of electric car power inverters promises even greater contributions to the efficiency, intelligence, and environmental value of tomorrow’s transportation systems.