Inverter Brushless Motor

What Is an Inverter Brushless Motor?

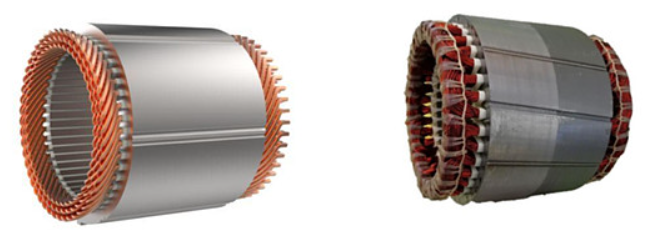

An inverter brushless motor—commonly referred to as a BLDC inverter motor—is a high-efficiency electric motor that combines brushless DC motor technology with advanced inverter-based electronic control. Unlike traditional brushed motors that rely on mechanical commutation, an inverter brushless motor uses solid-state power electronics to control the flow of current to the stator windings, eliminating brushes and commutators.

This design delivers multiple advantages:

-

Higher efficiency through reduced friction and electrical losses

-

Longer lifespan due to minimal wear and tear

-

Compact and lightweight construction for high power density

-

Precision control of speed and torque over a wide operating range

Inverter brushless motors are widely used in electric vehicles, HVAC systems, robotics, industrial automation, and high-performance appliances due to their combination of reliability, quiet operation, and precise motion control.

description2

How BLDC Inverter Motors Work: From Power Electronics to Motion

The operation of a BLDC inverter motor starts with DC power—typically from a battery or rectified AC source—which is fed into an inverter. The inverter’s role is to convert DC into a three-phase AC waveform, precisely timed to energize the stator windings in sequence.

Here’s the process step-by-step:

-

Power Input

The motor receives DC power from a battery, solar array, or power supply. -

Inverter Conversion

The inverter uses semiconductor switches (such as MOSFETs or IGBTs) to generate controlled three-phase AC signals from the DC source. -

Electronic Commutation

Instead of mechanical brushes, the motor uses electronic commutation—Hall-effect sensors or sensorless algorithms detect rotor position, and the inverter energizes the correct stator coils at the right time. -

Electromagnetic Rotation

The energized stator windings create a rotating magnetic field, which interacts with permanent magnets on the rotor to produce torque. -

Feedback and Optimization

The inverter continuously adjusts voltage, frequency, and current to optimize efficiency, torque output, and speed based on load conditions.

This seamless integration of power electronics and motor design allows BLDC inverter motors to deliver instant torque, high acceleration, and smooth operation with minimal noise.

description2

The Role of Inverter Control in Modern Motor Applications

Inverter control is the core intelligence behind modern brushless motor performance. By precisely modulating voltage and frequency, the inverter acts as both a motor driver and a performance optimizer.

Key roles of inverter control include:

-

Speed Regulation – Adjusts motor speed dynamically without mechanical gear changes, enabling smooth acceleration and deceleration.

-

Torque Optimization – Delivers the exact torque needed for the load, improving efficiency and reducing energy waste.

-

Energy Recovery – In applications like electric vehicles, inverter control enables regenerative braking, capturing kinetic energy and converting it back to electrical energy.

-

Thermal Management – Monitors motor temperature and adjusts output to prevent overheating, extending service life.

-

Advanced Control Algorithms – Implements methods such as Field-Oriented Control (FOC) and sensorless control for superior responsiveness and stability.

Modern inverter-controlled BLDC motors are transforming industries by enabling quiet, efficient, and highly controllable motion systems. They are a cornerstone of next-generation electric vehicles, smart appliances, and precision automation.

description2