Motor Revolution: How rare earth permanent magnet materials are reshaping the future of high efficiency and energy saving

As the core device that converts electrical energy into mechanical energy, motors serve as the power heart of modern industrial systems. From household appliances to heavy machinery, from transportation vehicles to industrial production lines, they drive the global economy. Traditional motors primarily utilize electromagnetic induction principles, where current generates magnetic fields in windings to rotate rotors. However, these motors exhibit significant energy efficiency limitations—— Their operation relies on continuous current excitation, with rotor winding losses accounting for 20%-30% of total energy loss, making it difficult to break through efficiency bottlenecks.

Research data reveals that motor systems account for 45%-50% of global electricity generation. In China, industrial motors alone consume up to 60% of the nation's total annual power usage. The situation is particularly dire: Due to design limitations and material constraints, many motors operate inefficiently for extended periods. Statistics show that approximately 46.3% of motors have load rates below 50%, with overall system efficiency typically under 40%. This staggering energy waste underscores the urgent need for material innovation and technological upgrades.

The core breakthrough of permanent magnet motors lies in replacing current excitation with permanent magnets, which completely eliminates rotor copper losses and achieves a qualitative leap in motor efficiency. Among various permanent magnet materials, rare earth permanent magnets have become the "soul material" for high-end, high-efficiency motors due to their outstanding magnetic properties. The incorporation of these materials not only significantly improves motor efficiency at full load but also maintains excellent power performance metrics (the product of efficiency and power factor) under partial load conditions.

The global rare earth permanent magnet market is experiencing unprecedented rapid growth. According to QYR's statistics, the global market sales reached $12.52 billion in 2024 and are projected to climb to $24.95 billion by 2031. In the specialized field of motor permanent magnet materials, growth remains robust, with sales expected to hit RMB 206.28 billion by 2031, achieving a compound annual growth rate (CAGR) of 7.5%.

The application of rare earth permanent magnet materials in motors has completely reconstructed the efficiency boundary and power density limit of motors. Its core value is reflected in three aspects:

1.A revolutionary increase in efficiency

Rare earth permanent magnet synchronous motors achieve an average 5%-8% efficiency improvement over traditional induction motors under full load conditions. Specialized models (e.g., oil field pumping unit motors) can even reduce energy consumption by 15%-20%. This advantage stems from eliminating rotor winding losses – a critical factor: approximately 20%-30% of total losses in induction motors originate from rotor current. Permanent magnet motors fundamentally resolve this issue by utilizing permanent magnets to provide a stable magnetic field.

2. Significant optimization of volume and weight

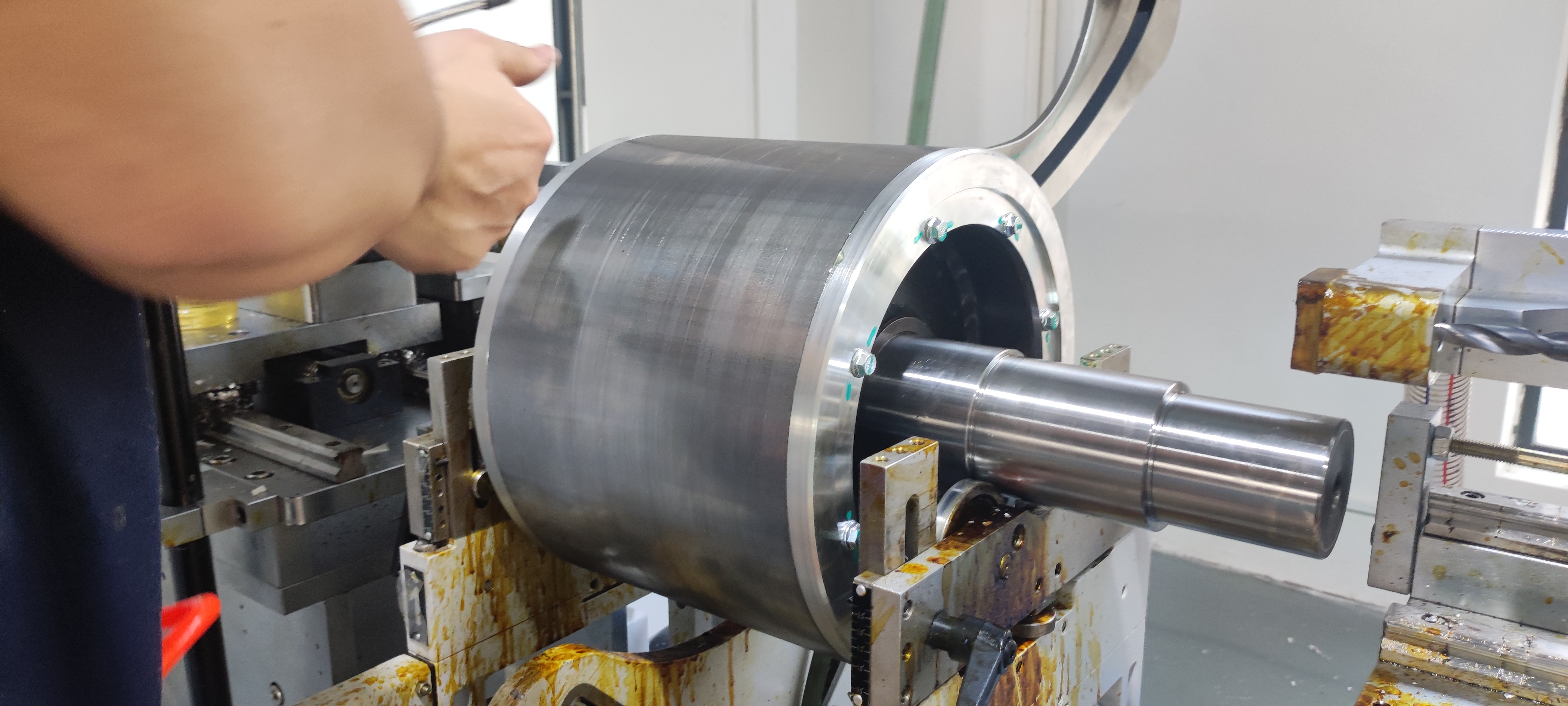

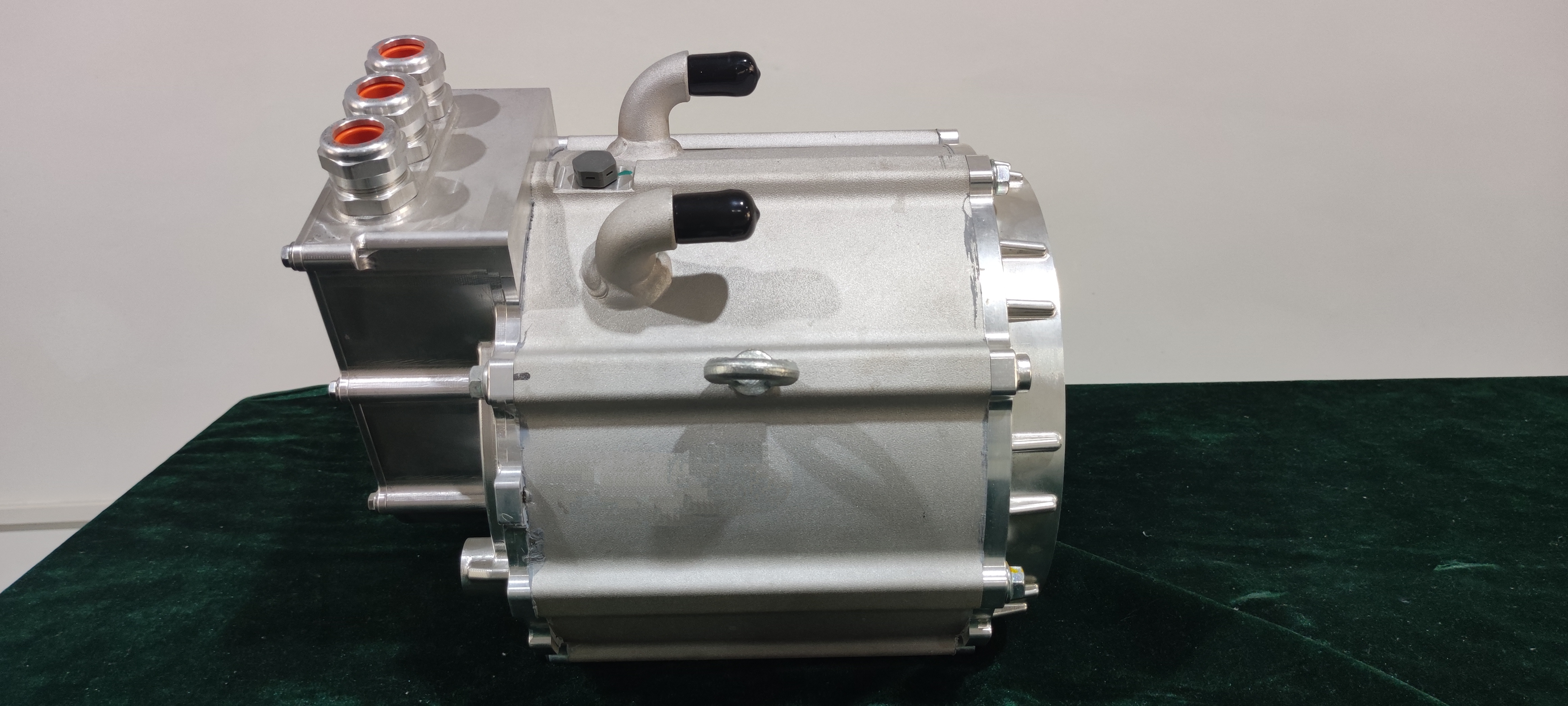

The exceptional magnetic energy product of neodymium iron boron (NdFeB) enables motors to achieve significantly smaller sizes while delivering equivalent power output. Recent case studies demonstrate that permanent magnet drive units can reduce their volume by 50% while boosting torque by 30%. This characteristic proves particularly crucial in electric vehicle and aerospace applications. A prime example is France's 100kW brushless motor for aviation – weighing merely 28kg yet achieving over three times the power density of conventional motors.

3. The absolute advantage of light load performance

In practical applications, most motors operate under partial load conditions. Studies reveal that only 18.1% of motors run at over 75% load, with nearly half operating below 50%. Traditional induction motors experience significant efficiency and power factor drops during light loads, whereas permanent magnet motors demonstrate exceptional performance: At 22% rated load, their power-efficiency ratio (efficiency × power factor) remains as high as 80%, compared to 30% for induction motors at 25% load. This broad economic operating range makes permanent magnet motors an indispensable choice for variable-load applications such as variable-frequency air conditioners and CNC machine tools.

Mainstream rare earth permanent magnet materials and technical trends

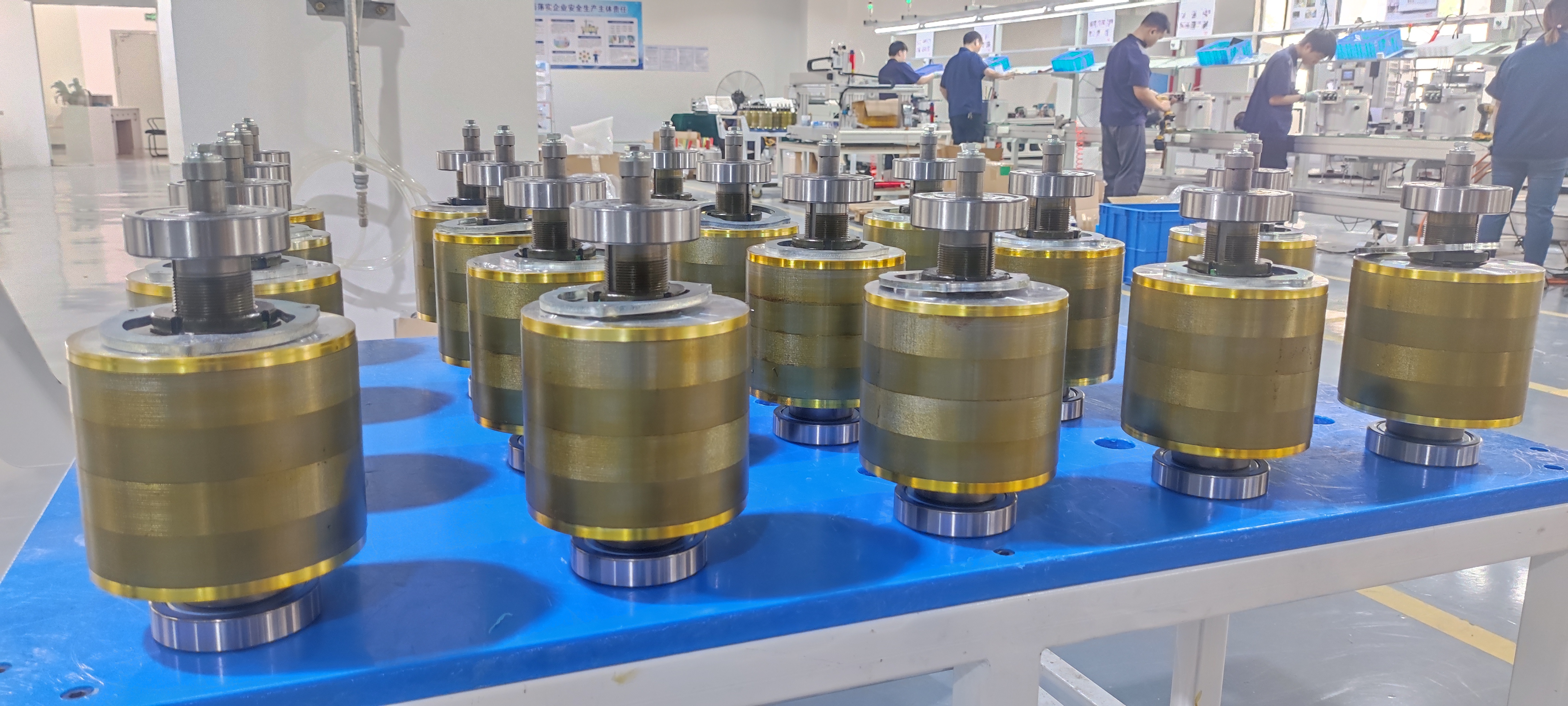

1.Performance Comparison of Three Categories of NdFeB Materials Currently, rare earth permanent magnet materials used in motors are mainly divided into three categories, each with its specific applications: Sintered NdFeB: The mainstream choice, accounting for over 90% of production. Manufactured through powder metallurgy, it offers optimal magnetic performance with a maximum energy product exceeding 50 MGOe, widely applied in new energy vehicle drive motors and wind turbines. However, its drawbacks include high brittleness and low yield rates when processing complex shapes. Bonded NdFeB: Accounts for less than 10%. Mixed with epoxy resin and pressed into shape, it excels in forming intricate structures (such as thin-walled rings) and achieving high dimensional accuracy, though its magnetic performance is only 60-70% of sintered material. Primarily used in hard disk drives and small stepper motors. Hot-pressed NdFeB: Requires high technical barriers and limited production. Through hot deformation processes to obtain highly oriented nanocrystalline structures, it matches the magnetic performance of sintered materials while offering better corrosion resistance. Currently mainly used in automotive EPS motors, it achieves high coercivity without requiring heavy rare earth dysprosium additives, making it a strategic material for premium markets.

2. Dual Drivers of Technological Evolution Current technological development focuses on two key directions: Resource-side innovation: In July 2025, China discovered a new rare earth mineral called "Neodymium Yellow River Ore" at the Bayan Obo deposit, characterized by high neodymium enrichment. This discovery could enhance neodymium extraction efficiency and alleviate supply pressures on critical resources for the new energy vehicle industry. Meanwhile, advancements in recycling technologies have accelerated the process of recovering neodymium iron boron magnets from waste motors, achieving 95% rare earth element recovery rates and gradually establishing a closed-loop resource system.

Motor Design Revolution: Collaborative innovation between materials and motor systems is becoming a trend. Taking the closed-loop vector control technology developed by Baizheng Chuangyuan as an example, this technology, combined with the characteristics of permanent magnet motors, has achieved "four-layer safety protection" for underground rail cars, including breakthroughs such as full-speed range stepless speed regulation and 100% braking energy recovery. Additionally, the heavy rare earth-free formulation technology reduces dysprosium and terbium usage through grain boundary diffusion process, maintaining high coercivity while reducing costs. This technology has been mass-produced by multiple leading enterprises.

Application scenarios: from green energy to intelligent equipment

1. New Energy Vehicles: The Main Battlefield for Drive Motors As the "heart" of electric vehicles, drive motors have extremely stringent performance requirements. High-performance neodymium iron boron (NdFeB) magnets can enhance torque density and efficiency, directly extending driving range. Currently, the new energy vehicle sector accounts for nearly 12%* of global demand for high-performance NdFeB magnets, with per-vehicle usage continuing to grow. Taking the mainstream Model 3 as an example, its permanent magnet synchronous motor uses approximately 4 kilograms of NdFeB blocks. Meanwhile, BYD's Haibin employs an eight-in-one electric drive system that further optimizes magnetic circuit design, achieving a 15% improvement in magnetic material utilization.

2. Wind Power Generation: The "Backstage Driver" of Clean Energy Direct-drive permanent magnet wind turbines eliminate gearbox requirements by harnessing direct interaction between rotor magnets and stator coils for power generation. This design reduces mechanical failure points and enhances the reliability of offshore wind energy systems. A single 6MW direct-drive turbine consumes approximately 1.2 tons of neodymium iron boron (NdFeB), while global wind power installed capacity is projected to exceed 2,000GW by 2030, driving sustained demand for high-end magnetic materials.

3. Industrial Energy Saving: A Transformation Tool for High-Energy-Consuming Industries Rare earth permanent magnet variable frequency motors demonstrate significant energy-saving potential for variable load systems such as pumps and fans. The national mandatory standard GB18613-2020 sets IE3 as the minimum energy efficiency threshold, driving enterprises to phase out inefficient motors.

4. Emerging application scenarios: robotics, high-end equipment and mining innovation.

In July 2025, China's launch of rare earth permanent magnet rail cars marked a revolution in mining transportation. These vehicles feature maintenance-free permanent magnet motors with a lifespan of 100,000 hours, reducing maintenance costs by 50% while delivering 2.5 times the rated torque at startup – effectively solving the challenge of heavy-duty uphill climbing in underground mines. Furthermore, emerging fields such as humanoid robot joint micro-motors and precision linear motors for semiconductor equipment all rely on the miniaturization and high-precision characteristics of neodymium iron boron (NdFeB).

The integration of rare earth permanent magnet materials with motor technology has transcended mere component upgrades, emerging as a pivotal force driving global industrial green transformation. From powering the surge of new energy vehicles to ensuring stable output in wind turbines; from enabling heavy-duty mining trucks to conquer steep slopes to enabling dexterous robotic joints. Under the global consensus of the "dual carbon" goals, rare earth permanent magnet motors will continue to expand their application boundaries, reshaping every dynamic moment from energy production to industrial consumption.