E-Axle: The Silent Powerhouse Reshaping Electric Mobility & Heavy-Duty Drives

Engineers face unprecedented challenges: while battery packs devour every inch of chassis space, and 95% transmission efficiency remains an unbreakable glass ceiling, the market demands more—longer range, higher power, and smoother performance. The complex mechanical symphony of the internal combustion era reveals its cumbersome inefficiency in the quiet revolution of electrification. Decoupled layouts—separate motors, gearboxes, and controllers connected via wiring harnesses and brackets—not only consume valuable space but also embed energy losses at every conversion stage.

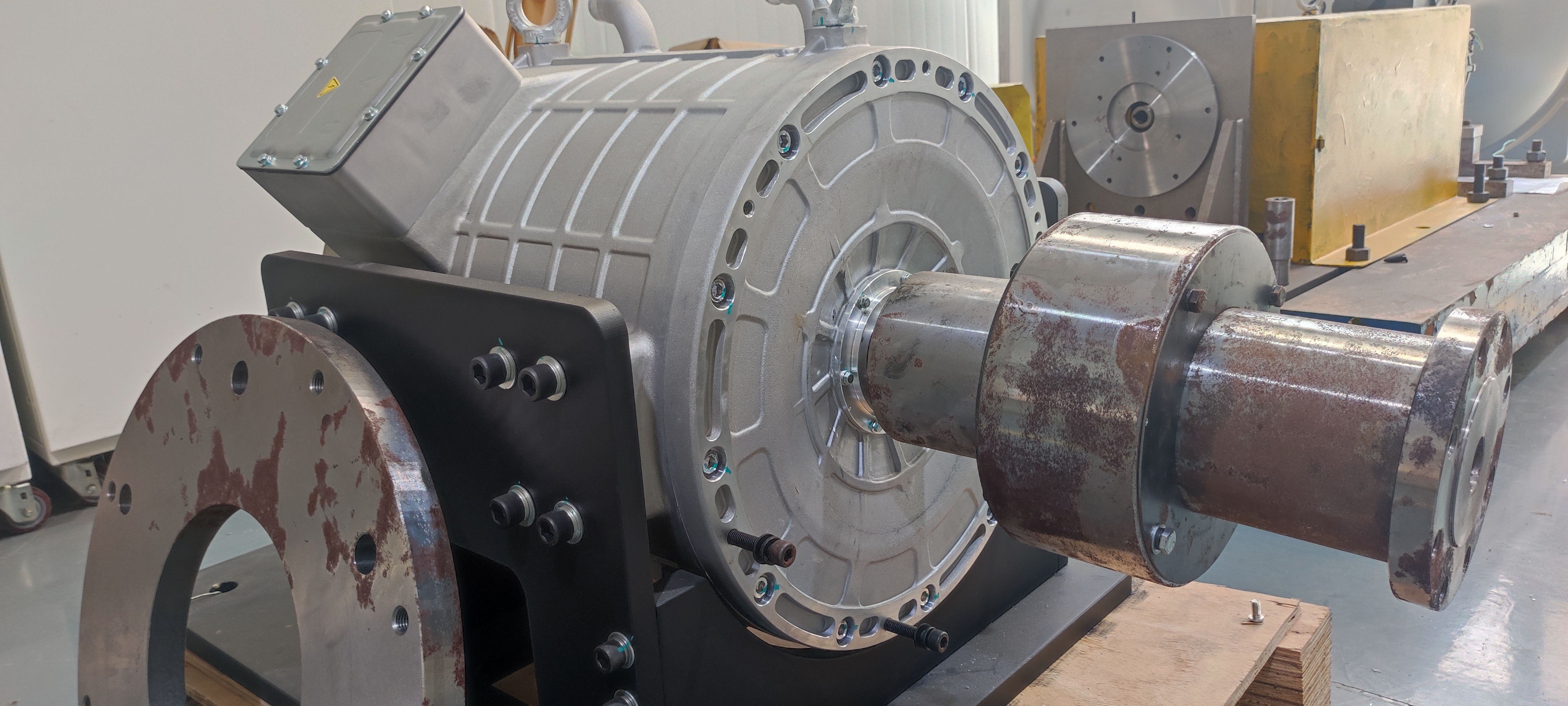

This is no mere upgrade but a fundamental reengineering. The emergence of the e-Axle marks the evolution of powertrains from "mechanical assemblies" to "electronic drive organs." By integrating motors, reduction gears, and power electronics into a compact housing, it liberates physical space while rewriting the rules of efficiency, performance, and control logic.

E-Axle Anatomy: Why "High-Density Integration" Is the Survival Code of the Electric Era

The essence of "multi-in-one" integration extends far beyond saving space. It represents a systemic revolution in energy flow, thermal management, and vehicle dynamics.

-

The Art of Spatial Reconfiguration:

For vehicle architects, e-Axles deliver precious "spatial negentropy." The deeply nested design of planetary gear sets and hairpin flat-wire motors pushes power density beyond 45 kW/L. Liberated space enables larger batteries, more flexible suspension layouts, or superior crash safety structures—shifting engineering priorities from "how to fit" to "how to optimize."

-

The Hardcore Logic of Efficiency Leap:

Eliminating mechanical drive shafts is just the beginning. The true efficiency code lies in materials science and control chips. Next-gen inverters built on silicon carbide (SiC) MOSFETs elevate efficiency curves with higher switching frequencies and lower conduction losses. Paired with direct oil-cooling technology, which bathes hairpin winding ends in coolant, heat dissipation reaches unprecedented levels. System energy loss plummets from >7% to <3%—every watt saved directly extends driving range.

-

Reengineering Handling DNA:

When left and right half-shafts are no longer rigidly linked by mechanical differentials, control dimensions expand exponentially. Native torque vectoring allows millisecond-level torque distribution to outer wheels during cornering, generating yaw moments that guide the vehicle like rails. This replaces traditional ESP braking "corrections" with electric "pre-shaping" and "active guidance," transforming cornering from compromise to precision.

The Devil’s Lair: Engineering Hell for Mass-Produced e-Axles

Bridging the gap between lab prototypes and mass-produced units capable of surviving 10 years or 300,000 km requires conquering an "engineering hell." High-density integration compresses historically separate challenges—NVH (Noise, Vibration, Harshness), thermal management, electromagnetic compatibility (EMC), and mechanical reliability—into a sealed housing, forcing them to interact with unprecedented intensity.

-

The Micro-Battlefield of NVH:

At motor speeds exceeding 16,000 rpm, with planetary gears enduring cyclic stresses measured in tons, micron-level tooth profile errors or bearing clearances amplify into unbearable whines or resonances. This war is waged at the frontier of micro-geometry and material fatigue.

-

Thermal Management’s Paradox Triad:

A single oil circuit must cool high-temperature SiC modules, lubricate high-speed gears and bearings, anddissipate motor heat. Conflicting optimal temperature zones turn flow distribution into high-stakes art—local overheating triggers chain failures.

-

EMC’s Invisible War:

In ultra-compact spaces, high-voltage/high-current switching (dv/dt, di/dt) generates intense electromagnetic interference. This must be contained, absorbed, and filtered withinthe housing to prevent leakage into vehicle networks or the environment—demanding electromagnetic fortification from chip layout to busbar design and shielded enclosures.

"It is in this engineering crucible that Pumba EV forged its competitive edge. We know e-Axle supremacy hinges not on peak specs, but on stable output under extreme conditions and end-of-life reliability."

Our counterattack is a full-stack engineering system spanning materials, design, and manufacturing:

-

Housing: The Rigid-Flex Foundation:

High-pressure vacuum die-casting combined with locally embedded reinforcements and carbon-fiber-reinforced composite supports strikes the precise balance between extreme lightweighting and resistance to massive axial/radial impacts.

-

Gears: Nanometer Silence:

AI-vision-guided honing and grinding delivers tooth surface roughness (Ra) consistently below 0.2μm. This isn’t just data—it enables "whisper-quiet" meshing at peak power, slashing gear rattle noise.

-

Electromagnetic Fortress:

Integrated design from PCB stacking and low-inductance laminated busbars to multi-layer EM-shielded composite housings. Active gate driving dynamically suppresses voltage overshoot, ensuring compliance with stringent CISPR 25 Class 5 standards.

-

Thermal Management Maze:

Dual-loop zoned cooling channels with independent flow control and thermal strategies for high-temp power modules and low-temp gearboxes. Intelligent algorithms maintain hotspot differentials within ±3°C, eliminating thermal runaway.

This culminates in our automated production line. Robotic arms execute hundreds of core processes—from stator pressing and planetary gear alignment to precision oil filling. Every e-Axle undergoes extended full-load endurance testing before shipment—100% inspection, not sampling. We deliver not components, but hardened, ultra-reliable "drive organs."

Beyond Passenger Cars: Heavy-Duty and Specialized e-Axle Evolution

The e-Axle story extends far beyond sedans. By unifying power, transmission, and control, it unlocks electrification for heavy-duty and specialized vehicles:

-

Commercial Vehicles: Revolutionizing Efficiency & Control:

Dual e-Axle architectures enable electronic differentials and intelligent inter-axle torque distribution. On icy or muddy terrain, systems instantly redirect power to wheels with grip, boosting traction by 30%+. Eliminating transfer cases and drive shafts cuts weight, increasing payload capacity and reducing energy consumption.

-

Construction Machinery: Power Meets Precision:

In excavators and loaders, e-Axles directly drive tracks or swing platforms. Millisecond torque response outperforms hydraulic systems, enabling faster, more precise movements. Critically, braking energy regenerates to power implements, boosting overall efficiency by 25%+.

-

Specialized Vehicles: Conquering Extreme Environments:

For mining trucks and airport tugs, e-Axles’ high-torque/low-speed capabilities synergize with planetary gears’ inherent durability. Our reinforced variants feature IP6K9K protection against pressure washing and dust ingress, plus anti-corrosion coatings for chemical exposure.

The Tipping Point: Next-Gen e-Axle Battlegrounds

Technology never rests. The next e-Axle frontier revolves around:

-

Voltage Platform Leap:

800V+ architectures paired with full-SiC power modules will boost efficiency by 1.5–2% while shrinking size/weight.

-

Material Revolution:

Nanocrystalline/amorphous alloy stator cores combat high-frequency iron losses—key to ultra-high-speed efficiency. Polyimide-ceramic hybrid insulation (220°C+) edges toward maturity.

-

Deep System Intelligence:

e-Axles evolve from actuators to smart sensors. Torque-predictive pre-cooling/pre-heating algorithms prevent thermal derating. Fail-operational architectures maintain >50% torque output during controller failures—critical for L4+ autonomy.

At Pumba EV’s R&D center, these are not concepts but active validations:

-

Dual-sided cooling pushes SiC module power density/thermal limits.

-

Active damping control neutralizes driveline torsional vibrations in real time.

-

Zonal e-Axle architectures deeply integrated with autonomous driving systems.

Call to Action: Partner with the Drive Reengineers

Choosing an e-Axle isn’t selecting a component—it’s joining a revolution redefining vehicle propulsion. This revolution hinges on ultimate energy efficiency, extreme dynamic performance, and the limitless potential of future E/E architectures.

Pumba EV’s e-Axle solutions already power diverse platforms—from supercars chasing 0-60 mph records to mining giants demanding 800 km daily range. We don’t sell shelf products; we co-create with partners to deliver scenario-conquering, highly customized drive arsenals.

Discover how next-gen integrated e-Axles can shatter your product’s efficiency, performance, and space boundaries.

www.pumbaaev.com

Transform every precise current pulse into undeniable driving force. Join us to define the future of motion.