Explosive Growth in the Electrification of Construction Machinery: How Can Motors Achieve Technological Breakthroughs?

It is reported that the global electrification rate for construction machinery was still below 2% in 2025. However, industry forecasts suggest that after achieving technological breakthroughs and substantial cost reductions, this penetration rate is expected to exceed 30%. From high-altitude tunnels to deep-sea mines, electric drive systems are becoming the core driving force behind the green transformation of construction machinery. Major markets such as China, the United States, and the European Union have all identified electrification as the future strategic direction for the construction machinery sector, signaling a market transformation worth trillions.

I. The Industry Wave

The electrification of construction machinery is no longer a conceptual idea but an unfolding reality. Since 2024, China has newly released 20 national standards related to construction machinery, with 13 more under development, all focused on the transition towards electrification, intelligence, and green development. This series of standards covers the entire industrial chain, from terminology and complete machines to energy consumption testing and power battery safety, providing technical support for the industry's high-quality development. The standardization not only reduces the risk of failures but also promotes the concentration of resources in leading enterprises.

II. Performance Challenges

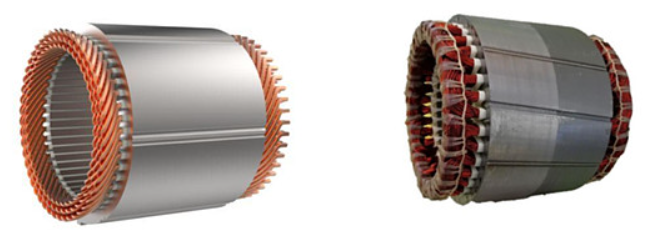

The core challenge for the electrification of construction machinery lies in meeting performance requirements under extreme operating conditions. Compared to traditional fuel-powered systems, electrified systems must overcome three major hurdles: energy conversion efficiency, operational duration (range), and battery cost. Professional motors must withstand the construction machinery's characteristic severe load fluctuations, intense vibrations, and strong impacts. Voltage adaptability has also become a critical metric. Electrified construction machinery products need to cover a power range from 20 kW to 200 kW, with input voltage adapting to a wide range of 270–850 V. The issue of power attenuation in high-altitude environments also requires specific solutions. Cooling systems are another key focus for technological. The cooling system must incorporate high-strength insulation design to ensure the motor's efficiency meets the Grade 2 energy efficiency requirements specified in the GB30254-2013 standard.

III. Technological Breakthroughs

The development of electrification technology for construction machinery exhibits distinct stages. The first stage primarily involved replacing the fuel-powered energy system with an electric one, while retaining the traditional centralized hydraulic architecture.

The second stage began to partially replace hydraulic transmission with electric drive systems.

The third generation of technology is advancing toward a highly integrated direction.

Low-speed, high-torque permanent magnet direct-drive motor technology has emerged as a significant breakthrough. These motors directly drive the load without needing a gear reducer, which can substantially reduce the energy consumption of the drive system and enhance the reliability of mechanical equipment.

The advancement of intelligent control systems also opens new possibilities for the electrification of construction machinery.

IV. Applications

The application of electrification in construction machinery has expanded across various scenarios. In the mining sector, products like electric excavators and electric mining trucks have achieved commercial application.

The infrastructure construction field is also experiencing the penetration of electrification. Electric construction machinery products have been rapidly adopted in major national projects such as the Sichuan-Tibet Railway, successfully addressing issues like power output decline in high-altitude environments and the high transportation costs for key spare parts and fuel.

In urban construction projects, products such as electric mixer trucks and electric pump trucks are gradually gaining popularity. It is reported that in July 2024, the domestic penetration rate of electric wheel loaders reached 15.7%, a year-on-year increase of 11.1 percentage points. The penetration rates of new energy mixer trucks, mining trucks, and heavy-duty trucks are also continuously rising. In terms of overseas market expansion, China's electric construction machinery products have successfully entered the international high-end market based on their technological advantages. Zoomlion's pure electric mixer truck, compliant with EU CE certification standards, has successfully entered the German market.

V. Dual Opportunities

The future development of construction machinery electrification is driven by two key forces: cost reduction and technological iteration.

Lithium batteries account for up to 40% of the cost breakdown for electric construction machinery. Therefore, reducing lithium battery costs is central to enhancing the competitiveness of electrified construction machinery. China possesses the world's most comprehensive and advanced lithium battery industry chain. The cost of lithium iron phosphate (LFP) batteries is 17% lower than in South Korea and 40% lower than in the United States, providing China's construction machinery electrification with a significant cost advantage. Regarding technological iteration, improving the efficiency of electric drive systems and increasing battery energy density will be the primary directions. The current core factors hindering the increase in the electrification rate of construction machinery are the high battery costs and limited operational duration (range) resulting from the relatively low energy conversion efficiency of hydraulic systems. As the dual carbon strategy advances, the electrification of construction machinery will become a crucial component of global green mine construction.